I'm having trouble trying to figure out how to put my air scoop on the highest pipe in the system. Problem is its pretty close to the ceiling in the boiler room. Can it go in the horizontal pipe between the boiler and the tanks. That piece won't be as high of an elevation as the horizontal piece that goes into the top of the top tank. ?

Air scoop location

- Thread starter nwomatt

- Start date

-

Active since 1995, Hearth.com is THE place on the internet for free information and advice about wood stoves, pellet stoves and other energy saving equipment.

We strive to provide opinions, articles, discussions and history related to Hearth Products and in a more general sense, energy issues.

We promote the EFFICIENT, RESPONSIBLE, CLEAN and SAFE use of all fuels, whether renewable or fossil.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

- Status

- Not open for further replies.

tuxedoblack11

New Member

- Feb 3, 2014

- 9

Try to locate it as near top of the piping as possible. I wouldn't recommend an air scoop as they are pretty much useless compared to a spirovent air eliminator. They offer both horizontal and vertical if space is a constraint.I'm having trouble trying to figure out how to put my air scoop on the highest pipe in the system. Problem is its pretty close to the ceiling in the boiler room. Can it go in the horizontal pipe between the boiler and the tanks. That piece won't be as high of an elevation as the horizontal piece that goes into the top of the top tank. ?

You should do a search on air scoops there is a lot on them. You want to purge the air from the highest location but you should have the scoop or Spirovent style located just before your primary circulator and expansion tank. However if you are using a loading valve that is not necessarily where you want the Spirovent. With a loading valve you would have the expansion tank then loading valve then circulator & boiler and then on your hot water out... Then you would put the Spirovent.

It really depends on the placement in the overall system. "Hot Rod" has written about this.... Ideally you want placement at point of lowest pressure which would be just before a circulator.

It really depends on the placement in the overall system. "Hot Rod" has written about this.... Ideally you want placement at point of lowest pressure which would be just before a circulator.

STIHLY DAN

Minister of Fire

Keep in mind a spirovent can suck air in. I personally don't like them on the lowest pressure area. Have seen many issues in that application.

BoilerMan

Minister of Fire

This is from improper design. Sorry to be blunt, but that is the science of hydronics.Keep in mind a spirovent can suck air in. I personally don't like them on the lowest pressure area. Have seen many issues in that application.

TS

STIHLY DAN

Minister of Fire

This is from improper design. Sorry to be blunt, but that is the science of hydronics.

TS

Yes it is, But sucks air in no the less, there is improper design all over the place.

Keep in mind a spirovent can suck air in. I personally don't like them on the lowest pressure area. Have seen many issues in that application.

How can that be? If the system is pressurized to even 3-4PSI it

Yes it is, But sucks air in no the less, there is improper design all over the place.

I don't see how it would be physically possible to admit air into the system if there is anything close to normal operating pressure in the boiler regardless of location.

Any and all automatic vents working with a float will be open to the atmosphere if there is no pressure so a typical Taco or B&G vent on top of a CI air scoop would do the same thing.

As has been said above, the best place for the air scoop is right on top of the expansion tank and that assembly should be located just "upstream of the main circulator in the system regardless of actual elevation.

Installing a purge setup (boiler drain/ball valve/boiler drain) at the appropriate spot in any system will get rid of 95% of the air when filling the system initially.

STIHLY DAN

Minister of Fire

OK, seems people don't understand so here is a quick, crude example. Circ pump on the return of boiler which used to be done all the time. expansion tank on the supply side put in at stock 12-15 psi. 3 story home, Spirovent on the return so you start at 12 psi feeding all 3 floors retuning at 0 or less psi before pump. This happens often. More so on larger commercial heating or cooling applications. I have gone to a number of calls where the pump keeps getting air bound and this is the problem, I have stood there and watched it happening. Many plumbers have no idea of head pressure, pressure drop, or velocity. I am NOT saying that as a blanket statement or accusing, anyone here of not being a good plumber. Or implying that one should know these things. There are many variables with heating/cooling with water.

Here is my problem, even though with a gas not the wood boiler, and wonder if it was caused by the spirovent sucking air when the primary pump and boiler shut down due to an error code. The Taco 011 overheated and made a clicking sound when I caught the error. The Taco Zone Controller still saw a call for heat so the secondary pump was running but the boiler was in error mode and shut down. Thus a big drop in pressure. I corrected the error--apparently the boiler was sucking exhaust through the concentric vent under those particular atmospheric conditions, so I'll have to raise the interior exhaust pipe above the exterior air pipe to separate them more. In the meantime I just disconnected the air and will be sucking it from the house temporarily.

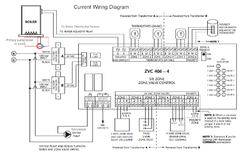

I guess I will have to figure out how to wire the pumps to be sure this doesn't happen again. I put them on separate circuits so it will be a challenge to shut the secondary down when the other goes off. But should I also move the spirovent? I'm using the existing manifold system for the zones so the hot is below the cold return. I was going to pipe the hot on top but decided I didn't want to turn all the zone valves around.

Here is a photo of the system and the Taco pump that was damaged is in the red rectangle. It will cost $160 to buy the rebuild kit. Rats.

I guess I will have to figure out how to wire the pumps to be sure this doesn't happen again. I put them on separate circuits so it will be a challenge to shut the secondary down when the other goes off. But should I also move the spirovent? I'm using the existing manifold system for the zones so the hot is below the cold return. I was going to pipe the hot on top but decided I didn't want to turn all the zone valves around.

Here is a photo of the system and the Taco pump that was damaged is in the red rectangle. It will cost $160 to buy the rebuild kit. Rats.

STIHLY DAN

Minister of Fire

No, the expansion tank is keeping it pressurized. Unless it's flooded, but even then I doubt it. It's really not that common, I was just stating that it CAN happen.

Thanks for that thought, this is a pretty new setup, so I doubt it was flooded. The spirovent did its job and had trickled all the air out, which I could tell by the noise in the pipes fading away. I had bled the system but there was still some air in it.

The tank is a bit further from the spirovent than normal but not so far that it wouldn't keep the system under pressure I guess. Still, the pump did fail. As long as I have it apart thought I'd ask about moving the spirovent too. Would rather not have to rethink the piping again though.

The tank is a bit further from the spirovent than normal but not so far that it wouldn't keep the system under pressure I guess. Still, the pump did fail. As long as I have it apart thought I'd ask about moving the spirovent too. Would rather not have to rethink the piping again though.

Vizsla

New Member

It takes a pretty seriously bad design to admit air via any air elimination device. Like 2 stories above the waterlevel on an open system. Or how about a pl-36 pump were a 15-58 was originally. A 40psi differential and more at starts and stops.

I think you might be going overboard with spirovents letting air in. Every thread that comes up. Anything is possible in any circumstance, but extremely rare and unlikely.

I think you might be going overboard with spirovents letting air in. Every thread that comes up. Anything is possible in any circumstance, but extremely rare and unlikely.

Your circ needs mounted horizontal for the water to properly lubricate the bushings, unless system pressure is higher than 35psi (if memory serves me right).

the best location for a central air removal device is at the highest temperature point, or close to the outlet of the boiler. It doesn't really need to be up high in the piping to work an many vertical devices are now used on wall hung type boilers.

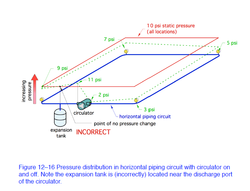

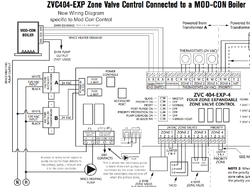

It is possible to pull some air into a float type vent if you pull low of negative pressure at the vent. An example would be a medium or high heat pump pumping at the expansion tank. Depending on the delta P the circ develops you can, and will suck air into a closed loop system. The drawing below photo credit: Modern Hydronic Heating shows a fairly small circ pumping towards an expansion tank in a system with a 12 psi static fill pressure. Imagine if this system had a pump capable of a 8-10 psi or higher delta P, you would have negative pressure at the inlet. If the air purger was located there, problems will arise.

A micro bubble type of air eliminator is a multi pass device, it may take several hours to expel the air if you didn't have a clean purge when you filled. As long as the air is pumping around the piping and flowing through the air separator, it will be captured and released.

Unless of course the air valve is plugged or the float stuck inside.

http://www.caleffi.us/en_US/caleffi/Details/Magazines/pdf/idronics_2_2007_us.pdf

It is possible to pull some air into a float type vent if you pull low of negative pressure at the vent. An example would be a medium or high heat pump pumping at the expansion tank. Depending on the delta P the circ develops you can, and will suck air into a closed loop system. The drawing below photo credit: Modern Hydronic Heating shows a fairly small circ pumping towards an expansion tank in a system with a 12 psi static fill pressure. Imagine if this system had a pump capable of a 8-10 psi or higher delta P, you would have negative pressure at the inlet. If the air purger was located there, problems will arise.

A micro bubble type of air eliminator is a multi pass device, it may take several hours to expel the air if you didn't have a clean purge when you filled. As long as the air is pumping around the piping and flowing through the air separator, it will be captured and released.

Unless of course the air valve is plugged or the float stuck inside.

http://www.caleffi.us/en_US/caleffi/Details/Magazines/pdf/idronics_2_2007_us.pdf

Attachments

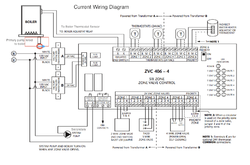

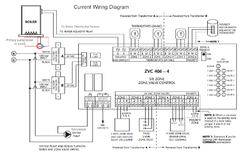

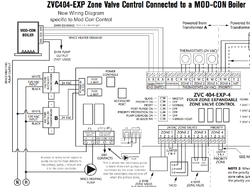

I didn't see the last 2 posts--thought I was getting email updates but guess not. Fixed the pump and the system is back in operation. In case anyone gets back to this perhaps hijacked thread. The pump is situated horizontal and pumps away from the spirovent and the pressure tank and fill valve are located below the vent on the hot supply side. So unlikely that it drew in air and failed. Could have just failed even without the situation where the secondary pump was pumping and the primary was not. I found a Taco wiring guide that is specific to the type of boiler I am using (gas in this case not wood which I'm still hooking up.)

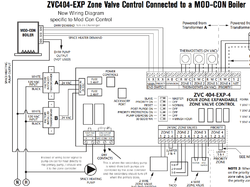

It is a wall hung mod con and the primary pump is controlled by the boiler while the secondary is controlled by the Taco zone control. I have to re-wire it so that the boiler control is sent to the zone control instead of directly to the pump and that should avoid the problem I had in the future.

The difference is shown in these diagrams:

It is a wall hung mod con and the primary pump is controlled by the boiler while the secondary is controlled by the Taco zone control. I have to re-wire it so that the boiler control is sent to the zone control instead of directly to the pump and that should avoid the problem I had in the future.

The difference is shown in these diagrams:

Attachments

I completed the rewire and it appears to be working well. Both pumps are triggered now by the boiler but they are switched through the taco zone controller. They will either both be on or off now. A little different from the wiring suggested by the boiler installation instructions but make sense after the secondary pump overheated during a fault condition and again when the hot water heater priority shut down the boiler while the call for heat was still active. I've noticed these pumps run pretty hot, but I have read that is normal. Thanks for the help with the original air intake issue.

- Status

- Not open for further replies.

Similar threads

- Replies

- 8

- Views

- 687

- Replies

- 2

- Views

- 570

- Replies

- 0

- Views

- 1K

- Replies

- 8

- Views

- 1K