- Oct 3, 2007

- 1,539

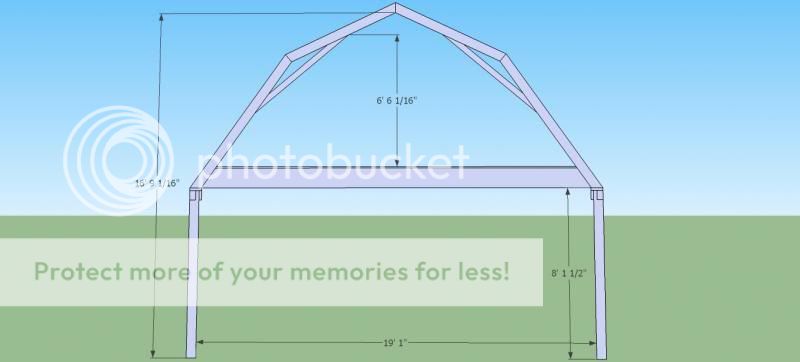

I came up with another idea for a pole barn because the last one I was thinking of building would have been too small. This one will be 16 x 24, so not overly large, but probably the biggest I can accommodate on my .25 acre lot. Here's the basic idea:

-6 x 6 x 12' poles sunk 48" deep

-2 x 6 pressure treated girt board around the bottom

-2 x 12s bolted to the inside and outside of the tops of the 6 x 6s (is that overkill?)

-2 x 2 x 16 floor joists for the loft, 16" OC

-3/4" OSB subfloor up top

-Home built gambrel roof trusses made from 2 x 4 x 8s and OSB web plates on both sides spaced 24" OC

-Steel roofing and siding

-Sliding 8' wide door

-Compacted crusher run floor

I figure I can build it for about $5000 doing the work myself, the question is, is it a sound design? I'm basing it off of a barn I saw built on another forum and am pretty much copying it exactly. The guy was in Indiana so it definitely sees plenty of snow. Here's a cross section of the framing:

The goal is as small a footprint as possible with as much storage as possible, hence the huge gambrel truss. That's the part I'm wondering about the most. Should I use 1 x 6 bracing instead of the OSB webbing?

-6 x 6 x 12' poles sunk 48" deep

-2 x 6 pressure treated girt board around the bottom

-2 x 12s bolted to the inside and outside of the tops of the 6 x 6s (is that overkill?)

-2 x 2 x 16 floor joists for the loft, 16" OC

-3/4" OSB subfloor up top

-Home built gambrel roof trusses made from 2 x 4 x 8s and OSB web plates on both sides spaced 24" OC

-Steel roofing and siding

-Sliding 8' wide door

-Compacted crusher run floor

I figure I can build it for about $5000 doing the work myself, the question is, is it a sound design? I'm basing it off of a barn I saw built on another forum and am pretty much copying it exactly. The guy was in Indiana so it definitely sees plenty of snow. Here's a cross section of the framing:

The goal is as small a footprint as possible with as much storage as possible, hence the huge gambrel truss. That's the part I'm wondering about the most. Should I use 1 x 6 bracing instead of the OSB webbing?

Yeah...pretty sure the weight of the plywood would collapse the floor if I used 2 x 2 x 16s

Yeah...pretty sure the weight of the plywood would collapse the floor if I used 2 x 2 x 16s  I think max span for #2 Doug Fir 2 x 12s is 17'. My span will only be 14' 10" between the inside eve headers. Maybe I should look at using 2 x 10s instead to save a little $$$ I'll look into the 14' poles too-the big box stores don't have them but the local lumberyards might.

I think max span for #2 Doug Fir 2 x 12s is 17'. My span will only be 14' 10" between the inside eve headers. Maybe I should look at using 2 x 10s instead to save a little $$$ I'll look into the 14' poles too-the big box stores don't have them but the local lumberyards might.