Now that storage design is solidified, the next phase of my boiler planning is sorting out the heat distribution.

Current setup is two zones which seem grossly out of balance and an oil boiler with a pump of unknown size. I figure it its strong enough to circulate through zone 1, it's got to be blasting water through zone 2, which is supported by the extremely loud creaking and popping I hear from the radiators when zone 2 valve opens.

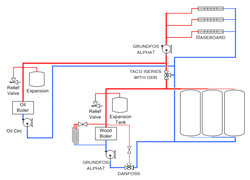

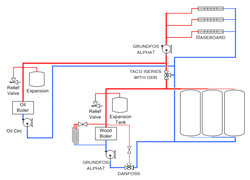

For my new setup I was inspired by the simplicity of Noah's constant circulation with ODR setup. While I don't have radiant emitters (yet) I do have way more baseboard than needed which I'm hoping will allow me to run lower water temps and get more out of my storage. I'd like to split the big zone in two so I end up with three roughly equal zones. I'll ditch the zone valves, go to constant circulation and use a 3-way Taco iSeries mixing valve with ODR to vary water temp to match demand.

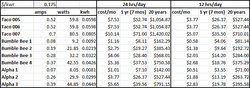

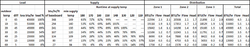

In the little spreadsheet, calculations are based on 180 water. In the big spreadsheet, the flow/head calculations are based on the BTU/hr needed to match heat loss but if I understand the Taco circulator selection PDF, that is really just the minimums required to move that amount of heat... targeting 2-4 gpm flow in all zones at all temps seems like it would work. Also min supply temp is really min average supply temp.

In terms of balancing the system, rooms with more baseboard/sq ft will be warmer than those with less... same with those at the beginning of the zone vs the end. I'm figuring I can plumb the rooms with less to get heat first and maybe it will all work out. If not, I can pick the next highest ODR curve and wrap some foil around the fins of the hot room. If whole zones are too warm, maybe I can throttle down flow with a ball valve?

For the oil boiler backup I will keep the thermostats and bypass the mixing valve, straight to zones. Heat loss calcs are some estimation, some experience. Over time I hope to improve insulation to reduce load and add radiant in different parts of the house.

I've crunched lots of numbers and on paper at least this seems like it might work, however I also read this article and just math doesn't cut it. Also apart from the published output charts (which I used in these calculations) I couldn't find much practical experience running low temp baseboards.

Looking for some input from the more experienced on potential pitfalls.

Current setup is two zones which seem grossly out of balance and an oil boiler with a pump of unknown size. I figure it its strong enough to circulate through zone 1, it's got to be blasting water through zone 2, which is supported by the extremely loud creaking and popping I hear from the radiators when zone 2 valve opens.

For my new setup I was inspired by the simplicity of Noah's constant circulation with ODR setup. While I don't have radiant emitters (yet) I do have way more baseboard than needed which I'm hoping will allow me to run lower water temps and get more out of my storage. I'd like to split the big zone in two so I end up with three roughly equal zones. I'll ditch the zone valves, go to constant circulation and use a 3-way Taco iSeries mixing valve with ODR to vary water temp to match demand.

In the little spreadsheet, calculations are based on 180 water. In the big spreadsheet, the flow/head calculations are based on the BTU/hr needed to match heat loss but if I understand the Taco circulator selection PDF, that is really just the minimums required to move that amount of heat... targeting 2-4 gpm flow in all zones at all temps seems like it would work. Also min supply temp is really min average supply temp.

In terms of balancing the system, rooms with more baseboard/sq ft will be warmer than those with less... same with those at the beginning of the zone vs the end. I'm figuring I can plumb the rooms with less to get heat first and maybe it will all work out. If not, I can pick the next highest ODR curve and wrap some foil around the fins of the hot room. If whole zones are too warm, maybe I can throttle down flow with a ball valve?

For the oil boiler backup I will keep the thermostats and bypass the mixing valve, straight to zones. Heat loss calcs are some estimation, some experience. Over time I hope to improve insulation to reduce load and add radiant in different parts of the house.

I've crunched lots of numbers and on paper at least this seems like it might work, however I also read this article and just math doesn't cut it. Also apart from the published output charts (which I used in these calculations) I couldn't find much practical experience running low temp baseboards.

Looking for some input from the more experienced on potential pitfalls.

Last edited: