Does anyone know of a source of information regarding the variables that control the rate at which wood fuel will burn and how to calculate that burn rate if those variables are known? Also, what controls the minimum possible burn rate achievable by limiting the primary air to just enable continuing gasification, i.e. the file is just self-sustaining?

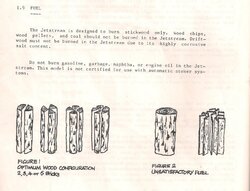

I have a free source of wood that is unfortunately all mixed sizes, from normal splits to almost twigs. I would like to get a handle on how much faster the smaller bits could be burning and if this can damage the combustion chamber if I overload it with such small stuff.

Aside from that, the information would just be interesting to know!

I have a free source of wood that is unfortunately all mixed sizes, from normal splits to almost twigs. I would like to get a handle on how much faster the smaller bits could be burning and if this can damage the combustion chamber if I overload it with such small stuff.

Aside from that, the information would just be interesting to know!