Hi All, I've read a lot on this forum about the gasification boilers and it looks like an ideal heating solution for me. We have been supplementing our oil furnace with a old fireplace insert the last two winters and it has worked out very well. We live on 15 acres of dense forest and have been cutting walking trails and a small area for a meadow, as such I have more wood than I could ever hope to burn.

The reasons I want to add a wood boiler and use it instead of the current insert are

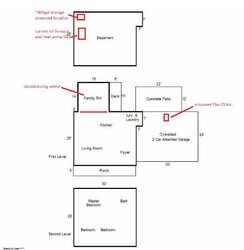

The Eko 25 seems like a good fit, as we are not replacing our current heating system, only adding the wood in parallel. Would also like to add radiant to the family room and a modine type water to air heater in the garage for occasional use. The garage is very well insulated as well and the current 3kW electric heater does a decent job making it comfortable in there.

At some point it makes sense to add a sidearm heat exchanger to the input to the GE heat pump water heater, but I don't want to get ahead of myself yet!

Thoughts? Feedback?

The reasons I want to add a wood boiler and use it instead of the current insert are

- we have a newborn and his main play area is the same room the fireplace is currently, would like to move the source of heat and smoke out of the living area

- Wife would like the bark and ash to stay out of the house

- Would like to add heat to the garage and to the family room off the back of the house (they are both heated by electric currently and thus not used often)

The Eko 25 seems like a good fit, as we are not replacing our current heating system, only adding the wood in parallel. Would also like to add radiant to the family room and a modine type water to air heater in the garage for occasional use. The garage is very well insulated as well and the current 3kW electric heater does a decent job making it comfortable in there.

At some point it makes sense to add a sidearm heat exchanger to the input to the GE heat pump water heater, but I don't want to get ahead of myself yet!

Thoughts? Feedback?