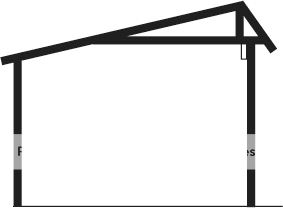

I've added some detail from the suggestions given here. Added in the diagonal bracing, hurricane clips, and bracing for the overhang. As drawn now the woodshed is 96 sq ft, I haven't check into local laws about permitting, tax implications, ect. yet. I wanted to have a good idea of what I was going to be building before I got into it too much. The slats on the wall as drawn are 1x6 dimensional lumber (.75 x 5.5 actual) with 2" spacing. This may change once I see it in person, its hard for me to picture what the right spacing would be.View attachment 127987

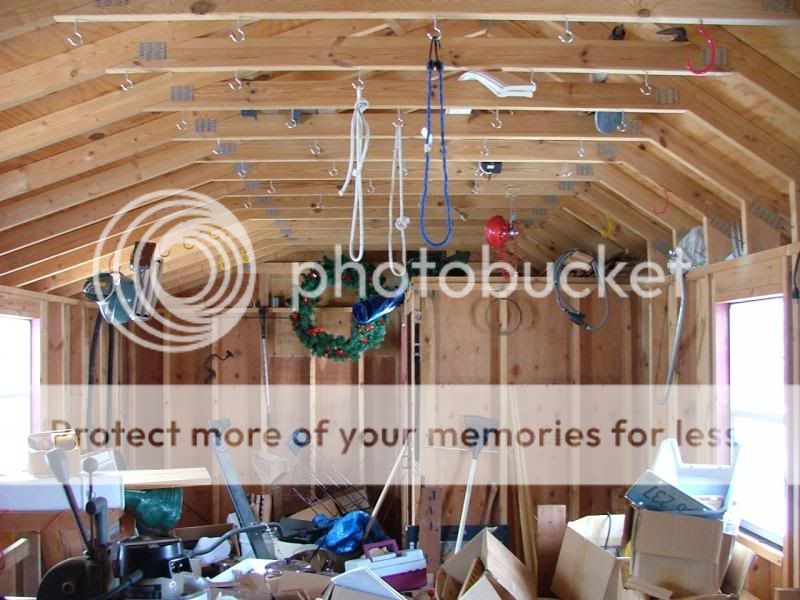

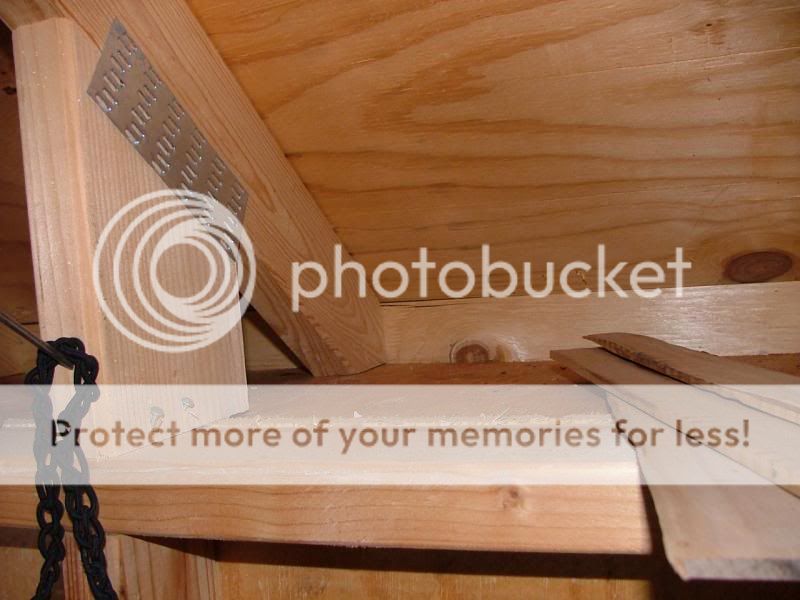

Throw some of these into the rafters. Very strong.

http://tcsportcharlotte.com/simpson-h11z-hurricane-clip-tie-z-max.aspx