New griddle gasket, old VC Intrepid

This is the second time since maybe Y2K that I replaced this gasket on my pre-1988 heater. It was long overdue. Sometimes when the fire was just starting, before the draft got going I would see a puff or two coming from the griddle seam. That's not supposed to happen!

The old gasket was a real bee-otch to get out. I used a flat blade screwdriver, mainly, and a hammer with a VERY gently touch. I also used a metal punch to drag the channel for cleaning, but the small flat blade worked best. I hammered the screwdriver forward, like a tiny chisel. It probably took me 45 mins to an hour. I'd think I was done, wipe some water on it, look again with a flashlight and there'd be more. I'm sure there's no need to clean it completely pristine. That's just me.

The night before I had broken one of the hinges off the griddle, so I was reminded how fragile are these old castings. The griddle fell against my arm as I was jockeying the last split in, and as I moved my arm to lessen the burn, I must have force the hinge on the right side against the piece of wood inside the stove.

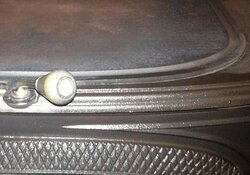

You can see with the new gasket the griddle sits way above the stove top. Before I changed it, it sat flush. That's how much the old one was compressed. I think I replaced it the first time back in 1999 or 2000.

The adhesive that WoodsmansPartsPlus dot com sold me along with the metallic mesh/fiberglass gasket is clear cement. The last time, I'm pretty certain, I did it with Rutland black. I pretty much filled the gasket channel with the clear stuff. It was messy. Of course I was wearing latex gloves. I don't even like to handle the gasket without gloves; there's stray fiberglass sticking out all over.

It's been a few weeks since I did this and there's absolutely no smoke any more thru the griddle when back-puffing. I also changed the location of the gasket seam. It was in the back, now it's in front. For a top loader, smoke is least likely to come out at the front of the griddle. I could have done a better job on the seam if I had cut both ends of the gasket, not just the one end for length. And maybe a 45* angle is best.

Looking at the pictures I can see it's time for some stove black.

This is the second time since maybe Y2K that I replaced this gasket on my pre-1988 heater. It was long overdue. Sometimes when the fire was just starting, before the draft got going I would see a puff or two coming from the griddle seam. That's not supposed to happen!

The old gasket was a real bee-otch to get out. I used a flat blade screwdriver, mainly, and a hammer with a VERY gently touch. I also used a metal punch to drag the channel for cleaning, but the small flat blade worked best. I hammered the screwdriver forward, like a tiny chisel. It probably took me 45 mins to an hour. I'd think I was done, wipe some water on it, look again with a flashlight and there'd be more. I'm sure there's no need to clean it completely pristine. That's just me.

The night before I had broken one of the hinges off the griddle, so I was reminded how fragile are these old castings. The griddle fell against my arm as I was jockeying the last split in, and as I moved my arm to lessen the burn, I must have force the hinge on the right side against the piece of wood inside the stove.

You can see with the new gasket the griddle sits way above the stove top. Before I changed it, it sat flush. That's how much the old one was compressed. I think I replaced it the first time back in 1999 or 2000.

The adhesive that WoodsmansPartsPlus dot com sold me along with the metallic mesh/fiberglass gasket is clear cement. The last time, I'm pretty certain, I did it with Rutland black. I pretty much filled the gasket channel with the clear stuff. It was messy. Of course I was wearing latex gloves. I don't even like to handle the gasket without gloves; there's stray fiberglass sticking out all over.

It's been a few weeks since I did this and there's absolutely no smoke any more thru the griddle when back-puffing. I also changed the location of the gasket seam. It was in the back, now it's in front. For a top loader, smoke is least likely to come out at the front of the griddle. I could have done a better job on the seam if I had cut both ends of the gasket, not just the one end for length. And maybe a 45* angle is best.

Looking at the pictures I can see it's time for some stove black.