Just realized I never did get back to update this thread last year... Whoops!

Anyway, I did swap the elbow above for a cleanout T, actually put a newer/easier thumb-screw style at the stove exit and put the older style up top and since it has a "[" handle I bolted some brass trim to that - bling!

For my 2014/2015 season I burned 3 tons of my Okie Plats, one from the prior year, plus some random 6-packs for testing. The old ton survived outside storage OK, but the new ones were considerably ashier. I'll try to get back and post my 6-bag test results for several different pellets. Hard to say for certain but it looks like those 3 tons (plus a cord and 3/4ton giant pellets) saved me at least 400 gallons of oil. Plus, for the first time in my 57 Massachusetts winters, I had a warm house...

I found that with the T replacing the elbow I had a lot less buildup in my horizontal pipe but more in my down pipe. Pretty much as I'd expect, and still not enough to worry about. A 1 hr clean every ton or so with a full breakdown end-of-season and it's good to go.

I did rig up a cap for my OAK and used a large red rubberband on the door to indicate it was in place. With that and a can of damp-rid I saw no new rust, although the paint is now pretty well blasted off my baffle and the heat exchanger does show a skim of surface rust. I suspect that's inevitable.

I have gotten exactly "nowhere" on either the back panel that doesn't fit a 4" double wall outlet pipe or on the vent kit. The change to the cleanout T pushed the exhaust pipe and therefore the stove a good 2" further from the wall, I want to make sure the vent kit fits before I try to push it back. Unfortunately the vent kit did not come with a block-off plate so I have to make something before I can put it all together, otherwise the heat will still come out in the basement room rather than go out the vent pipes.

So far for 2015/2016 I ran a few more 6-bag tests and have burned my leftover ton from last year. Since I started that ton then "took a break" trying other pellets before choosing this season's recipe, an enterprising rodent "moved in" despite my covers. I'm presuming chipmunks. Made a stinky icky mess of the bags but the pellets themselves were OK, albeit a touch odiferous. I deployed Irish Spring in vented covered "dishes" underneath the tons, hope that works this time. Last year I tried that I just left it in open containers and it got nibbled and shat upon etc.

I tried out a few pellets from a pellets direct cash-n-carry sale (plus a ton of giant pellets for the insert) and wound up needing a tow home - my truck failed its' stress test (3200lbs) and needs a new injector pump. That is actually good news since this was much better than finding this out with a camper and car trailer on the way to Nebraska. Nabbed my season supply from Hamshaw again but this year they're onto me, delivery jumped up to $50. Oh well. Not bad really at about $1/mile, but I got spoiled the last two years.

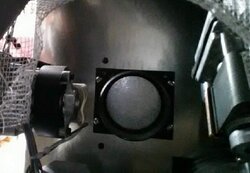

I've just done my first "1 ton clean" and found I'd packed some ash into the exhaust "manifold" although the fan itself looks fine. I think from the way it's running I've got some buildup in the vacuum port - I catch it "paused" every so often then resumes feeding with a faint click (quieter than a snap disk). Can't find it from the burnpot side, I guess I'll try blowing it out - from the switch end of the tube, of course.

I haven't yet started my cordwood insert, probably will this week. In the one really cold night so far I did kick the Maxx up to "4" and was surprised it was not a lot louder than at 3. Door temp went up a good 100 degF, I'm going to look forward to that setting once I've got the ducting worked out. Well, except for the increased consumption - this thing can eat some fuel!

I took a stab at adding some baffle to the burn pot to help reduce pellets going directly to the ash bin and getting burned there. Had a dead sawzall blade and broke it off symmetrically then JB-Welded it to the "flap", this worked reasonably until the stove cooled and the JB "no longer welded". I drilled and tapped a couple holes to capture it with screws. Here are some snapshots (added looong after this post, always meant to get better shots but these are better than nothing

):

Before (stock):

After:

In action:

.

This has significantly reduced, but not eliminated, raw pellets landing in the ash bin. I debated a bigger piece but didn't want to disrupt the airflow that much, not knowing what the "tolerance" would be to mucking with that...

Cheers/later,

- Jeff

):

):