hot water heater for storage

- Thread starter buck0123

- Start date

-

Active since 1995, Hearth.com is THE place on the internet for free information and advice about wood stoves, pellet stoves and other energy saving equipment.

We strive to provide opinions, articles, discussions and history related to Hearth Products and in a more general sense, energy issues.

We promote the EFFICIENT, RESPONSIBLE, CLEAN and SAFE use of all fuels, whether renewable or fossil. -

Super Cedar firestarters 30% discount Use code Hearth2024 Click here

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

- Status

- Not open for further replies.

Honestly , I thought about it but a lot of work for 40 -50 gallons. I can't figure out why a storage tank is so expensive. A round barrel with two 1" holes in it. How much can it really cost. I'm surprised some guy hasn't started making them and selling here on Hearth. Only has to hold 50PSI?

Honestly , I thought about it but a lot of work for 40 -50 gallons. I can't figure out why a storage tank is so expensive. A round barrel with two 1" holes in it. How much can it really cost. I'm surprised some guy hasn't started making them and selling here on Hearth. Only has to hold 50PSI?

3 reasons:

1. Codes

2: Product liability laws

3: Lawyers who love #2

Injured, scalded and burned children whose parents love lawyers who think products should not injure, scald and burn children. Otherwise, the market likely would be flooded with ... "Somewhere in the 22000 pounds range... I wouldn't trust a barrel."3: Lawyers who love #2

So, you're saying the pellet boiler runs at a lower output and keeps the buffer charged without the usual starts and stops? That's very nice. Do you still run the wood stove at all, and when you do, how does the boiler/tank react then? I'm thinking in terms of the stove heating the near areas and the boiler heating the farther areas.Using an 80 gallon Superstor as a buffer with my Kedel and it works great. I have usually 2-3 starts of the pellet boiler a day even in the heel season. If it wasn't for my day/night time set back it would run all day whenever its below 25*F or so.

So, below 25F, with the storage tank, the Kedel only runs 2 or 3 times a day to heat the 80 gallons?Using an 80 gallon Superstor as a buffer with my Kedel and it works great. I have usually 2-3 starts of the pellet boiler a day even in the heel season. If it wasn't for my day/night time set back it would run all day whenever its below 25*F or so.

No, If I didn't do setback on my thermostats in the house (like on weekends when we're home), the Kedel doesn't shut down at all unless it needs to clean itself which I have set for every 80 lbs.So, below 25F, with the storage tank, the Kedel only runs 2 or 3 times a day to heat the 80 gallons?

I don't NEED the buffer tank, but it greatly reduces cycling with a multiple zone baseboard set up. If I had radiant heat or radiators with TRV's I wouldn't have even considered using a buffer tank since circulation is constant, the flow to the zones simply vary.

My boiler only started twice today and only once yesterday.

I've been tempted to fire the Pensotti up to see how long it runs with the buffer tank. Buffers are really good for on/off systems as well especially when a 100mbtu boiler is firing on and off for a cycling 15mbtu zone.That's really great. My oil boiler cycles a bunch.

DZL_Damon,

Could you please describe more in detail how the buffer tank works with the pellet boiler? Does the boiler change its output when it charges the buffer or does it run at 100%

Would it have been possible to convert to constant circulation? I have no idea how that works.

Thanks.

Could you please describe more in detail how the buffer tank works with the pellet boiler? Does the boiler change its output when it charges the buffer or does it run at 100%

Would it have been possible to convert to constant circulation? I have no idea how that works.

Thanks.

DZL_Damon,

Could you please describe more in detail how the buffer tank works with the pellet boiler? Does the boiler change its output when it charges the buffer or does it run at 100%

Would it have been possible to convert to constant circulation? I have no idea how that works.

Thanks.

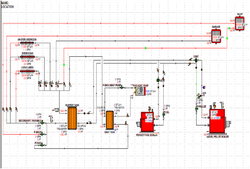

The boiler has its own pump that runs constantly into the top of the tank and pulls off the bottom. There is a 2nd pump that pulls off the top of the tank to the zones and returns at the bottom of the tank. I have x4 on/off zone valves and an indirect DHW loop. This is why I wanted to use the buffer tank so the boiler has room to modulate to higher firing rates and ramp down to lower firing rates when a zone shuts off. The boiler will slowly ramp down to idle and charge the tank up a little before the next zone valve calls vs having the boiler cycle on/off whenever a zone calls. The boiler does not have the thermostats connected to T-T to control it, the boiler only comes on when the buffer tank is down to 145*F and shuts off at 180*F. The boiler modulates to maintain 170*F output.

As for constant flow to the house, if I had that I wouldn't have installed the buffer tank. The constant flow system will vary how much high temperature water goes to the zone and how much gets bypassed and goes back to the boiler inlet. Since this is a gradual process and the zone is rarely off (just throttled) the boiler can easily follow the load needed to maintain temperature. Since on/off zones are abrupt, having 80 gallons of hot water already stored up it acts like a cushion so the boiler doesn't need to ramp to such a high firing rate and inversely ramp down to nothing (or shut off) after the zone is satisfied.

clear as mud?

Thanks. I think I have it now. What I didn't get was the boiler modulating its firing rate to maintain 170 in the buffer tank.

Can I ask a couple more details?

-The boiler modulates to maintain 170 but shuts off when the buffer tank is 180? How does that happen?

-Where do you have the sensor on the buffer tank? Near the top, I imagine? Is there a thermowell (if that's the right term)?

-I started another thread on understanding constant flow, but in my case, which uses 3 circ water pumps to the load (1 per floor and dhw), do variable speed pumps exist that modulate their flowrates to match the load, so instead of varying the temperature you are varying the flow?

Can I ask a couple more details?

-The boiler modulates to maintain 170 but shuts off when the buffer tank is 180? How does that happen?

-Where do you have the sensor on the buffer tank? Near the top, I imagine? Is there a thermowell (if that's the right term)?

-I started another thread on understanding constant flow, but in my case, which uses 3 circ water pumps to the load (1 per floor and dhw), do variable speed pumps exist that modulate their flowrates to match the load, so instead of varying the temperature you are varying the flow?

If there is no load (zone valves closed because it's warm) the boiler will go to 10% firing rate eventually as the outlet temperature starts to increase and the tank will start warming up. It will do this for about 2 hours or so if there is no more demand for heat, after that it will hit the high temperature in the tank and shut down. With that much hot water stored, I can circulate for about an hour to one of my zones before the boiler needs to come back on.

Sensor is 3/4 from the bottom. A small tank like this is surprisingly not that much different from the top and bottom. I have another sensor well at the bottom but that one had more wild fluctuations of temperature when a cold zone would cycle on... the top stayed more consistent so I used that one instead. I installed a thermowell in the original pressure relief valve location. The pressure relief is not necessary anymore since it's coupled with x2 boilers that have their own.

Sensor is 3/4 from the bottom. A small tank like this is surprisingly not that much different from the top and bottom. I have another sensor well at the bottom but that one had more wild fluctuations of temperature when a cold zone would cycle on... the top stayed more consistent so I used that one instead. I installed a thermowell in the original pressure relief valve location. The pressure relief is not necessary anymore since it's coupled with x2 boilers that have their own.

Vent on the top, it's not exactly the same as in the diagram (the software didnt have a tank set up this way). This tank does NOT have an internal coil in it, the boiler water and tank water are all the same.

Also, that aquastat at the bottom is not used to turn the Kedel on, it turns on the oil boiler if it's too cold for 10 minutes (a timer is wired in with it). I will move this sensor to the Kedel itself later when the heating season is over and I can put in the correct style thermowell that holds the aquastat right.

That's a fair amount of piping.

But it is acting as a boiler, so that's to be expected.

The only question that popped into my head, and it wasn't brilliant, was 'what kind of insulation is that? It kind of looks like the usual gray stuff from HD and the like, but maybe it's that more expensive rubbery stuff for A/C. I wasn't happy with the way the gray stuff didn't prevent condensation on cold water lines in my basement that was too damp last summer. It also melted when it got near the boiler outlet. And I did a great job mitering the elbows and everything-I think the foam is porus. I've had the rubbery stuff near the boiler for a while now and it hasn't melted.

But it is acting as a boiler, so that's to be expected.

The only question that popped into my head, and it wasn't brilliant, was 'what kind of insulation is that? It kind of looks like the usual gray stuff from HD and the like, but maybe it's that more expensive rubbery stuff for A/C. I wasn't happy with the way the gray stuff didn't prevent condensation on cold water lines in my basement that was too damp last summer. It also melted when it got near the boiler outlet. And I did a great job mitering the elbows and everything-I think the foam is porus. I've had the rubbery stuff near the boiler for a while now and it hasn't melted.

I got the insulation from F W Webb which is a regional commercial supplier. Its 1/2" thick foam insulation with self adhesive strips with an R value advertised of 3.2. The HD stuff is 3/8 usually. I have that thicker foam rubber like insulation on the 2 boilers piping which is all black iron to the ceiling. I started with some reclaimed fiberglass insulation reclaimed from demo'd projects at work, but I sadly got the wrong sizes or not nearly enough in the right size. I used some of that on a few short sections and couldn't believe how cool to the touch they were. The foam feels like 90*f or so when circling water. The fiberglass is encased with a reflective foil facing inward which helps with radiant heat loss tremendously.

I will be paying more attention in the future for demo'd insulation on piping systems at work. My next house will have as much of that as I can find.

And your remark about it being like a boiler is an excellent way to describe it really. Its the distribution point while the oil and pellet boiler simply supply the heat to it.

I will be paying more attention in the future for demo'd insulation on piping systems at work. My next house will have as much of that as I can find.

And your remark about it being like a boiler is an excellent way to describe it really. Its the distribution point while the oil and pellet boiler simply supply the heat to it.

- Status

- Not open for further replies.

Similar threads

- Replies

- 16

- Views

- 892

- Replies

- 5

- Views

- 1K

- Replies

- 8

- Views

- 733

- Replies

- 6

- Views

- 2K