Flatbedford

Minister of Fire

There is always this:

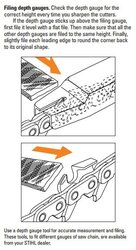

http://www.stihlusa.com/products/chain-saws/accessories/filing-tools/2in1file/

View attachment 130089

Suppose to lower your depth gauges as you file.

That looks pretty cool. Never saw that before. I found this youtube video on it.