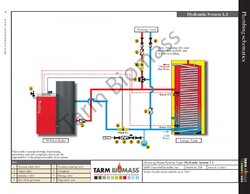

I wonder if anyone who's interested could please review my schematic, created in Taco's HSS (.hvp project file available upon request). I based it on the Tarm schematics for a Pellet Boiler with storage, hydraulic system 2.1, and for the pellet boiler with Energy Tank, hydraulic system 1.1, below.

( http://woodboilers.com/images/stories/documents/p4_pellet_plumbing_schematics_8.5x11.pdf )

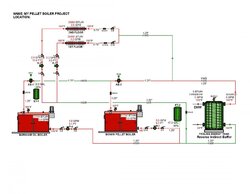

Several things:

-DHW not detailed

-Water addition, low level protection, etc, not yet represented

-I couldn't really figure out how to model the reverse indirect, which has 118 gal on the tank side and 11 gal in the dhw coil. It does indeed create big btu/hr draw-33k plus at 1gpm dhw flow

-The boiler outputs, pump gpms, head losses are CALCULATED based on the imposed baseboard loads, which come from measured baseboad lengths and characteristics and estimates of piping lengths.

-Attempted to model existing system, with location of expansion tank and air separator.

-Boiler pumps are new

Observations:

-The flo-chks add 1.5 ft head loss each

-It says the air separators adds 3 ft head each

Questions:

-The main question is: Will this work?

-Can I get maybe get away with one air separator, like a Spiro, by the pellet boiler and delete AS-1? They'll only be 6' apart or so, and the pellet boiler will be on most of the time.

-I've read that expansion tanks should go upstream of the pump. I did that with new ET-2 which should be larger than shown because ET-1 is really 4.4 gal, not 6.2 gal. Since I might be deleting AS-1 (original air scoop), I could also delete the original expansion tank, ET-1, and enlarge ET-2, so that they'll be upstream of the boiler pumps.

-Would auto pressure feed pumps be the way to go since there are three changing loads? Thing is, you would want excess boiler capacity to charge up the EnergyTank, but even only 1gpm provides 45,000 btu/hr. I'm leaning towars an auto pressure pump, e.g., and EcoCirc Auto.

Thanks.

VF

![p4_pellet_plumbing_schematics_8.5x11[1] 8.jpg p4_pellet_plumbing_schematics_8.5x11[1] 8.jpg](https://www.hearth.com/talk/data/attachments/131/131743-b6fb8759fc409df6c09a96e172744a8a.jpg)

( http://woodboilers.com/images/stories/documents/p4_pellet_plumbing_schematics_8.5x11.pdf )

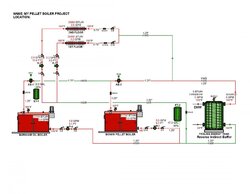

Several things:

-DHW not detailed

-Water addition, low level protection, etc, not yet represented

-I couldn't really figure out how to model the reverse indirect, which has 118 gal on the tank side and 11 gal in the dhw coil. It does indeed create big btu/hr draw-33k plus at 1gpm dhw flow

-The boiler outputs, pump gpms, head losses are CALCULATED based on the imposed baseboard loads, which come from measured baseboad lengths and characteristics and estimates of piping lengths.

-Attempted to model existing system, with location of expansion tank and air separator.

-Boiler pumps are new

Observations:

-The flo-chks add 1.5 ft head loss each

-It says the air separators adds 3 ft head each

Questions:

-The main question is: Will this work?

-Can I get maybe get away with one air separator, like a Spiro, by the pellet boiler and delete AS-1? They'll only be 6' apart or so, and the pellet boiler will be on most of the time.

-I've read that expansion tanks should go upstream of the pump. I did that with new ET-2 which should be larger than shown because ET-1 is really 4.4 gal, not 6.2 gal. Since I might be deleting AS-1 (original air scoop), I could also delete the original expansion tank, ET-1, and enlarge ET-2, so that they'll be upstream of the boiler pumps.

-Would auto pressure feed pumps be the way to go since there are three changing loads? Thing is, you would want excess boiler capacity to charge up the EnergyTank, but even only 1gpm provides 45,000 btu/hr. I'm leaning towars an auto pressure pump, e.g., and EcoCirc Auto.

Thanks.

VF

![p4_pellet_plumbing_schematics_8.5x11[1] 8.jpg p4_pellet_plumbing_schematics_8.5x11[1] 8.jpg](https://www.hearth.com/talk/data/attachments/131/131743-b6fb8759fc409df6c09a96e172744a8a.jpg)