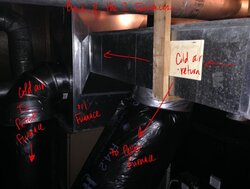

I recently had a Harman PF100 installed next to an existing oil furnace. I am wondering if the dampers were installed correctly. I am new to home ownership and the HVAC world so I don't know much about it but I don't think it was done properly. I am hoping for some answers as researching it didn't get me too far.

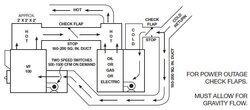

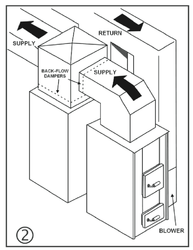

The installer placed dampers in the ductwork that connects the hot air plenum of the pellet furnace to the hot air plenum of the oil furnace. This way if the oil furnace did need to kick on it wasn't backfeeding air into the pellet furnace. I get that, it makes sense.

However, I am uncomfortable with this only because I felt like hot air was backfeeding into the oil furnace. I know this to be true because my oil furnace's blower will short cycle on and off as I assume it is trying to cool down.

Should there be a damper in my oil furnace's pelnum to stop the PF100's air from backfeeding into it, or does that not matter?

The installer placed dampers in the ductwork that connects the hot air plenum of the pellet furnace to the hot air plenum of the oil furnace. This way if the oil furnace did need to kick on it wasn't backfeeding air into the pellet furnace. I get that, it makes sense.

However, I am uncomfortable with this only because I felt like hot air was backfeeding into the oil furnace. I know this to be true because my oil furnace's blower will short cycle on and off as I assume it is trying to cool down.

Should there be a damper in my oil furnace's pelnum to stop the PF100's air from backfeeding into it, or does that not matter?