Hello.

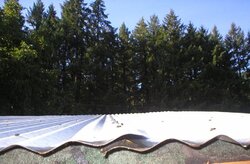

I have a 30 by 12 foot structure that is about 30-40 years old with 2X4 rafters @24"OC and a low slope shed type corrugated metal roof which is bright and shiny but leaking at the seams. I bought some BlackJack fibered roof coating for it But I need to seal the seams first before I coat the roof. It appears to be leaking Only because of the seams which are overlapped one corrugation and there doesn't appear to be any sealant in between them. I guess I need to get up there somehow and apply some sealant then tape then more sealant and then let that fix cure before I apply the aluminized fibered roof coating. I have Never done this before but it does sound simple enough. However I am concerned about the age and spacing of the 2X4 rafters (they are old but seem sound). Under the metal roofing is some old gritty tar [paper and under that are long 30 foot tongue & groove one inch boards.

Of course just getting up there will be an accomplishment cause I don't like ladders or openair heights. If I don't look down and concentrate on my Job though I should be ok.

Should I build some sort of scaffolding ? What would be the best way to do this job short of hiring out as I don't have the money to do that?

The front of the roof is about nine and a half feet high but I can reach the top of the back as it is less than six feet.

Any suggestions?

Thanks

I have a 30 by 12 foot structure that is about 30-40 years old with 2X4 rafters @24"OC and a low slope shed type corrugated metal roof which is bright and shiny but leaking at the seams. I bought some BlackJack fibered roof coating for it But I need to seal the seams first before I coat the roof. It appears to be leaking Only because of the seams which are overlapped one corrugation and there doesn't appear to be any sealant in between them. I guess I need to get up there somehow and apply some sealant then tape then more sealant and then let that fix cure before I apply the aluminized fibered roof coating. I have Never done this before but it does sound simple enough. However I am concerned about the age and spacing of the 2X4 rafters (they are old but seem sound). Under the metal roofing is some old gritty tar [paper and under that are long 30 foot tongue & groove one inch boards.

Of course just getting up there will be an accomplishment cause I don't like ladders or openair heights. If I don't look down and concentrate on my Job though I should be ok.

Should I build some sort of scaffolding ? What would be the best way to do this job short of hiring out as I don't have the money to do that?

The front of the roof is about nine and a half feet high but I can reach the top of the back as it is less than six feet.

Any suggestions?

Thanks

Incognito like.

Incognito like. to tear down and replace with a more proper building ... maybe even as a Very Large addition and connect the two and try to keep the old Barn look going so it all would fit in nicely up here.

to tear down and replace with a more proper building ... maybe even as a Very Large addition and connect the two and try to keep the old Barn look going so it all would fit in nicely up here.