We bought a new blaze king for this fall. I figure to get the most out of it, we should give it very dry wood. We have heated with wood for a long time. Up until now, we stored our cut/split wood under tarps that are on frames to keep it (mostly) off of the wood. That mostly worked, but it was hard to get the wood under 14-15% moisture content.

You will get long term reports of course, but the short term report is awesome!

This is a hoop house type greenhouse, made of 3/4" emt. It was relatively inexpensive to put up (well under a thousand dollars). It has plywood/framing walls for the ends, and 5 year greenhouse plastic for the roof/covering. You don't get much of a wood framed shed for a thousand bucks any more...

I think the key is that I put vapor barrier plastic down on the ground, because the ground can pump mass quantities of water vapor into a hot greenhouse. I put black tar paper over that, to give the sun something black to hit, and to protect the integrity of the vapor barrier somewhat. The second key is the 18 dollar box fan on a timer. There is a 21" window on each end, one holds the box fan and the other allows the hot humid air to leave. And man is it hot and humid.

I set the timer so the fan doesn't come on until 2 pm and the greenhouse is already quite hot. And it shuts off at 6:00, so I'm not spending a ton on electricity, and the fan runs when the moisture is removed most efficiently.

The greenhouse has a door on each end, so no old dry wood gets trapped by new/wet wood.

The wood is stacked on pallets.

I'll try to post a picture this week sometime.

Water can't get on the wood at all, and water (vapor) is being pumped out in a hurry by heat and forced circulation.

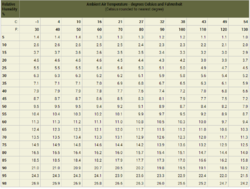

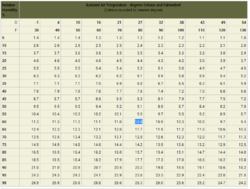

I know that more moisture = more wasted BTU's in my firewood. But how much? I thought I had seen a chart with moisture content on one axis and energy or efficiency lost on the other axis.

Any hard data laying around???

thanks!

troy

You will get long term reports of course, but the short term report is awesome!

This is a hoop house type greenhouse, made of 3/4" emt. It was relatively inexpensive to put up (well under a thousand dollars). It has plywood/framing walls for the ends, and 5 year greenhouse plastic for the roof/covering. You don't get much of a wood framed shed for a thousand bucks any more...

I think the key is that I put vapor barrier plastic down on the ground, because the ground can pump mass quantities of water vapor into a hot greenhouse. I put black tar paper over that, to give the sun something black to hit, and to protect the integrity of the vapor barrier somewhat. The second key is the 18 dollar box fan on a timer. There is a 21" window on each end, one holds the box fan and the other allows the hot humid air to leave. And man is it hot and humid.

I set the timer so the fan doesn't come on until 2 pm and the greenhouse is already quite hot. And it shuts off at 6:00, so I'm not spending a ton on electricity, and the fan runs when the moisture is removed most efficiently.

The greenhouse has a door on each end, so no old dry wood gets trapped by new/wet wood.

The wood is stacked on pallets.

I'll try to post a picture this week sometime.

Water can't get on the wood at all, and water (vapor) is being pumped out in a hurry by heat and forced circulation.

I know that more moisture = more wasted BTU's in my firewood. But how much? I thought I had seen a chart with moisture content on one axis and energy or efficiency lost on the other axis.

Any hard data laying around???

thanks!

troy

. 141 degree air temp is ferocious!

. 141 degree air temp is ferocious!