Snuck out & snapped some quick pics.

For me, 'easy collapsability' is a big thing so they don't take up so much room when they're empty, and you can move around a few at a time when empty & piled up.

I've got 2 configurations going on. Wire between the upper portions of the uprights are important to both. Double stack on both.

The first one is borrowed from wood handling on the farm. Main parts are 4x4. Uprights are boards. Here is collapsed, waiting for me:

Here is ready for wood:

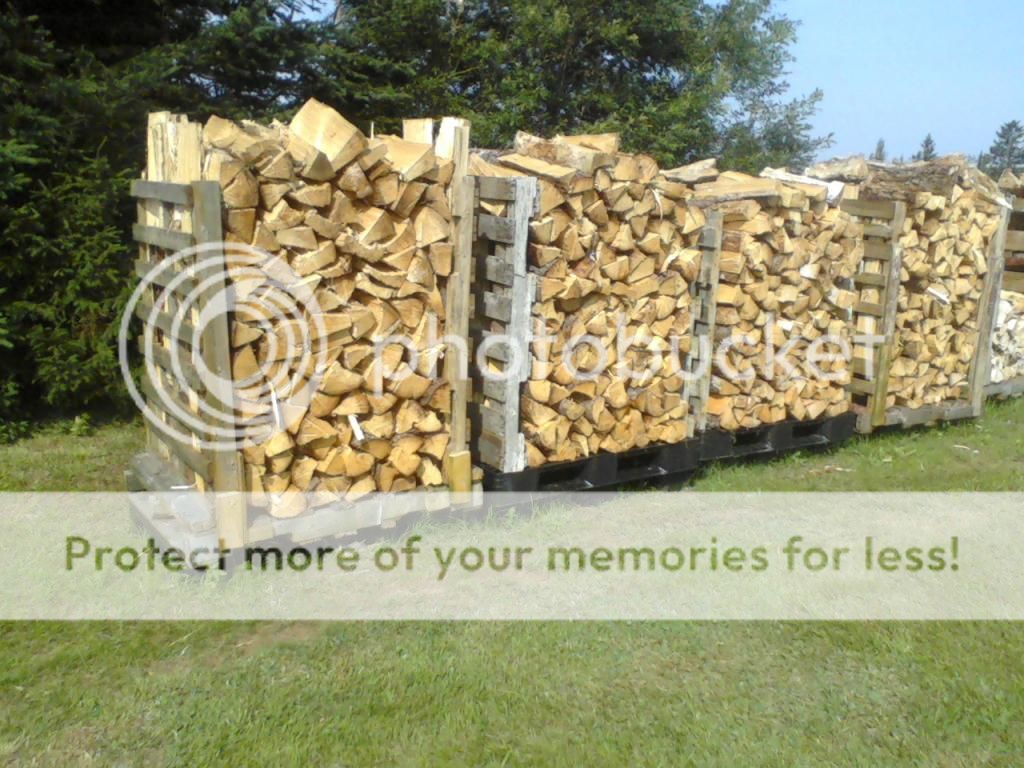

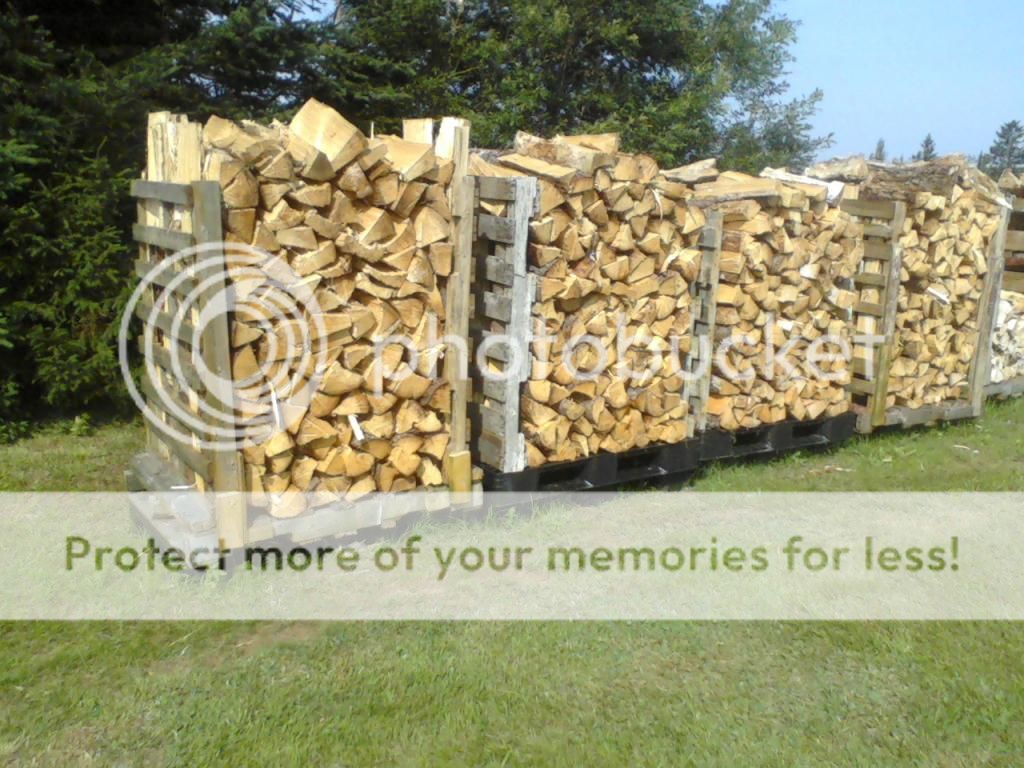

Here is some all piled up & drying:

Those ones get set on top of two dollies by the FEL, then wheeled into the basement. It's a real tight fit getting around a corner & through the second doorway & usually involves colourful language. So I came up with version 2, based on ordinary pallets, that I roll in with a pallet jack. V2.1 used wood pallets, v2.2 used some plastic ones I found last year.

Here is one half-full, this is wood that is way past prime & I'm getting rid of it over the summer while keeping our water hot. Shows the wire:

There is currently a hornets nest behind the upright of the pallet on the right - discovered the hard way last weekend.

Here's a few loaded & drying:

Collapsing is easy - pull each upright straight up out of the blocks or hole it's in, and lay them down. The plastic ones have an X brace buried in the middle, made out of 2 scrap pieces of metal drywall corner with a screw thru each end. Not likely necessary but figured I'd try it and I have all these pieces of drywall corner laying around.

Here's my unused as yet plastic pallets:

I got enough that I also now lay one on the ground before putting down & piling on the wood ones. So all my v2 pallets are sitting on a second plastic pallet that's just laying on the ground. The farther you can get them off the ground the better. The first type, I just set them on top of a split under each corner. And, I am trying to get them all sprayed with wood preservative as I go (everything wood), to try to help them last longer. Hopefully there's a few years in them between the preservative & keeping them off the ground.