My outdoor wood furnace is not exchanging heat very well between the furnace and the water and the water and the heat exchanger. I am guessing that there is corrosion or scaling built up from the sediment from the water. Does anyone know of a safe way to clean this out without ruining the heat exchanger. Does anyone know of any specific products that work well? I would greatly appreciate it because last winter I ended up using lp gas and paid through the nose with the high prices.

How to get rid of water corrosion

- Thread starter steviestevie88

- Start date

-

Active since 1995, Hearth.com is THE place on the internet for free information and advice about wood stoves, pellet stoves and other energy saving equipment.

We strive to provide opinions, articles, discussions and history related to Hearth Products and in a more general sense, energy issues.

We promote the EFFICIENT, RESPONSIBLE, CLEAN and SAFE use of all fuels, whether renewable or fossil.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

- Status

- Not open for further replies.

jebatty

Minister of Fire

Where is the corrosion occurring, in the furnace or in the heat exchanger? What type of heat exchanger do you have: water to water, water to air, plate, other, describe? Is the corrosion on the wood furnace side or on the heat to you house side of the heat exchanger? Describe the corrosion that is occurring. When did the corrosion first become evident? What did you do about that?

What is the type of outdoor wood furnace you have, how old is it, and what is the water capacity of the furnace? Have you ever tested the water in your outdoor furnace, and if so what were the test results? Have you used or do you use a water treatment for your outdoor furnace, and if so what is it?

Corrosion in hot water systems typically comes from oxygen in the water and/or water with pH which is acidic or not basic enough (low pH). There are other causes of corrosion as well, but oxygen and low pH likely are the most critical causes. If the corrosion is severe, it is possible that the hot water system itself has been seriously compromised with extensive damage that is not reversible.

What is the type of outdoor wood furnace you have, how old is it, and what is the water capacity of the furnace? Have you ever tested the water in your outdoor furnace, and if so what were the test results? Have you used or do you use a water treatment for your outdoor furnace, and if so what is it?

Corrosion in hot water systems typically comes from oxygen in the water and/or water with pH which is acidic or not basic enough (low pH). There are other causes of corrosion as well, but oxygen and low pH likely are the most critical causes. If the corrosion is severe, it is possible that the hot water system itself has been seriously compromised with extensive damage that is not reversible.

Phoenix Hatchling

Minister of Fire

My service contract for my boiler gives a simple going over every year. This year I had them run this stuff called "Sizzle" through it to clear out any scale build up. This process apparently had never been done by the previous owners either, and the difference it made was HUGE! They did need to install an extra valve in to allow it to be added, and circulated through the system.

jebatty

Minister of Fire

maple1

Minister of Fire

I don't think I've heard of the problem of corrosion causing poor heat conduction - I think it would be more likely that if corrosion was that present, it would be causing leaks first. It is quite common for heat exchangers to get scale or mineral buildup though especially in an open system that might see frequent water additions or replacements. What kind of boiler & HX and what is the age and service history of them? It should be possible to flush the HX with something common & harmless like CLR, but you might need to make some plumbing changes/additions first to get it done, if it wasn't set up for it to start with. Scale buildup in the boiler itself is another level of the same thing - might want to check with local OWB places or the manufacturer on product & methods.

And have you had this setup since it was new - or are you new to it?

And have you had this setup since it was new - or are you new to it?

TimfromMA

Minister of Fire

If you have a service contract, sounds like your contractor is the one to solve your problem.

In my experience, these service contracts do not cover the water portion of the boiler.

I have a Heatmoor wood furnace. I have noticed that over the years, it has taken longer and longer for the furnace to get the water hot at start up. I also noticed that the hot air going into my house has been less and less hot. I am guessing there is scaling from the hard well water I add to my unit every year, usually about 10 gallons a year. Sorry, I should have used the word scaling instead of corrosion in my description but I really don't know because I haven't seen the inside of my wood furnace and heat exchangers.Where is the corrosion occurring, in the furnace or in the heat exchanger? What type of heat exchanger do you have: water to water, water to air, plate, other, describe? Is the corrosion on the wood furnace side or on the heat to you house side of the heat exchanger? Describe the corrosion that is occurring. When did the corrosion first become evident? What did you do about that?

What is the type of outdoor wood furnace you have, how old is it, and what is the water capacity of the furnace? Have you ever tested the water in your outdoor furnace, and if so what were the test results? Have you used or do you use a water treatment for your outdoor furnace, and if so what is it?

Corrosion in hot water systems typically comes from oxygen in the water and/or water with pH which is acidic or not basic enough (low pH). There are other causes of corrosion as well, but oxygen and low pH likely are the most critical causes. If the corrosion is severe, it is possible that the hot water system itself has been seriously compromised with extensive damage that is not reversible.

Isn't Sizzle HCl (Hydrochloric Acid)? If it is, doesn't that corrode the metal in your furnace and heat exchangers?My service contract for my boiler gives a simple going over every year. This year I had them run this stuff called "Sizzle" through it to clear out any scale build up. This process apparently had never been done by the previous owners either, and the difference it made was HUGE! They did need to install an extra valve in to allow it to be added, and circulated through the system.

Phosphoric acid [available from Home Depot] will clean fine rust from a HX. It comes in gal jugs, and is sold as a tile cleaner. Probably a weak version too, if they sell it, but it does work. If you have rust in your tank, you shoud deal with that too.

jebatty

Minister of Fire

Hydrochloric acid (aka muriatic acid) is used to clean scale (lime and/or other mineral deposits) from hot water systems, but acid is extremely corrosive to steel and must be used under a regimen to insure that its harmful effects do not outweigh its beneficial use.

A swimming pool test kit can give a pretty good picture of boiler water chemistry: pH, total alkalinity, hardness. Boiler water must not be acidic, as acidic boiler water is very corrosive to steel. I have seen manufacturer recommendations for boiler water to have pH between 7.0 (neutral) and as high as 11 (high basic), although most seem to be in the range of about 8-9 (low basic). Drinking water standards allow pH of about 6-8.Using drinking water for boiler water with pH above 7.0 will result in steel corrosion.

EDIT FOR ERROR CORRECTION, SHOULD READ: Using drinking water for boiler water with pH BELOW 7.0 will result in steel corrosion.

In a pressurized, closed system, oxygen usually is not an issue as any entrapped oxygen quickly oxidizes metal components and then the oxygen's harmful effects are over. The system must not admit additional oxygen, and oxygen barrier pex or steel or copper pipe should be used.

In an open system, especially one in which additional water is added periodically or one which has large surface exposure to the atmosphere, oxygen admission can be a serious problem and may cause significant corrosion. Usually an oxygen scavenger chemical is used regularly to neutralize oxygen in such systems.

Hard water also can be a problem due to mineral content, especially again if additional water is added periodically.

A swimming pool test kit can give a pretty good picture of boiler water chemistry: pH, total alkalinity, hardness. Boiler water must not be acidic, as acidic boiler water is very corrosive to steel. I have seen manufacturer recommendations for boiler water to have pH between 7.0 (neutral) and as high as 11 (high basic), although most seem to be in the range of about 8-9 (low basic). Drinking water standards allow pH of about 6-8.

EDIT FOR ERROR CORRECTION, SHOULD READ: Using drinking water for boiler water with pH BELOW 7.0 will result in steel corrosion.

In a pressurized, closed system, oxygen usually is not an issue as any entrapped oxygen quickly oxidizes metal components and then the oxygen's harmful effects are over. The system must not admit additional oxygen, and oxygen barrier pex or steel or copper pipe should be used.

In an open system, especially one in which additional water is added periodically or one which has large surface exposure to the atmosphere, oxygen admission can be a serious problem and may cause significant corrosion. Usually an oxygen scavenger chemical is used regularly to neutralize oxygen in such systems.

Hard water also can be a problem due to mineral content, especially again if additional water is added periodically.

Last edited:

Do you know of any way to get rid of scaling without corroding the metal in the furnace and heat exchanger?Hydrochloric acid (aka muriatic acid) is used to clean scale (lime and/or other mineral deposits) from hot water systems, but acid is extremely corrosive to steel and must be used under a regimen to insure that its harmful effects do not outweigh its beneficial use.

A swimming pool test kit can give a pretty good picture of boiler water chemistry: pH, total alkalinity, hardness. Boiler water must not be acidic, as acidic boiler water is very corrosive to steel. I have seen manufacturer recommendations for boiler water to have pH between 7.0 (neutral) and as high as 11 (high basic), although most seem to be in the range of about 8-9 (low basic). Drinking water standards allow pH of about 6-8. Using drinking water for boiler water with pH above 7.0 will result in steel corrosion.

In a pressurized, closed system, oxygen usually is not an issue as any entrapped oxygen quickly oxidizes metal components and then the oxygen's harmful effects are over. The system must not admit additional oxygen, and oxygen barrier pex or steel or copper pipe should be used.

In an open system, especially one in which additional water is added periodically or one which has large surface exposure to the atmosphere, oxygen admission can be a serious problem and may cause significant corrosion. Usually an oxygen scavenger chemical is used regularly to neutralize oxygen in such systems.

Hard water also can be a problem due to mineral content, especially again if additional water is added periodically.

BTW the pH of the well water that I add to the boiler has a pH of 8.3Do you know of any way to get rid of scaling without corroding the metal in the furnace and heat exchanger?

jebatty

Minister of Fire

pH of 8.3 is good. Note my error correction above: "Using drinking water for boiler water with pH BELOW 7.0 will result in steel corrosion."

QuantityPewPew

New Member

Phosphoric acid [available from Home Depot] will clean fine rust from a HX. It comes in gal jugs, and is sold as a tile cleaner. Probably a weak version too, if they sell it, but it does work. If you have rust in your tank, you shoud deal with that too.

Isn't that stuff extremely dangerous? I mean its toxic even after use and might get into the air and therefore lungs and eyes...

Isnt there a non-toxic kind of way of doing it?

Isnt there a non-toxic kind of way of doing it?It's in CocaCola, how bad can it be? You'll have to look it up, read about it and decide if it's something you want to use. For me, with a plugged up [with rust] HX in January, short of buying a new HX, there was no other cure. Think about this though, ever since humans got tired of living in caves with no heat, trade offs have to be made - Whether it's wood smoke, oil spills, or by products from manufacturing our stoves & boilers, there are toxic products in most every step of it. I like to think I live as clean as anyone, certainly cleaner than the person that sprays every form of pesticide, herbicide, fertilizer, etc on their lawn. I guess I'm off topic a little now...........

I am still looking for a way to get rid of scaling without corroding the metal in my furnace and heat exchanger. Anyone have any solutions? I would greatly appreciate it.

Trex83

Member

I am still looking for a way to get rid of scaling without corroding the metal in my furnace and heat exchanger. Anyone have any solutions? I would greatly appreciate it.

Folks here have recommended citric acid, or phosphoric acid.

I gave 10% acetic acid to my father because i didn't want the brazed copper plate in the HX to get eaten away with phosphoric acid. Soaked it for a couple of hours and saw some deposits come out. It does work but is a "weak acid".

Good luck.

Bob Rohr

Minister of Fire

Folks here have recommended citric acid, or phosphoric acid.

I gave 10% acetic acid to my father because i didn't want the brazed copper plate in the HX to get eaten away with phosphoric acid. Soaked it for a couple of hours and saw some deposits come out. It does work but is a "weak acid".

Good luck.

I am still looking for a way to get rid of scaling without corroding the metal in my furnace and heat exchanger. Anyone have any solutions? I would greatly appreciate it.

Hercules Sizzle would be the correct product IF it is a scale build up from hard water. Yes, you do need to flush after the cleaning and it's best to check the ph.

Some of the brands of acid based cleaners are two part and you add the neutralizer after the acid has done it's work. Steward Hall, a RectorSeal brand is one of the two part products I have used.

The directions on the Sizzle bottle tell you how to blend it and flush. Sizzle has been used in boilers, DHW tanks and other heat exchangers for many years, proper use of any chemical is the key.

Hydrochloric is generally the "nasty" option, has the strongest effect, works quicker, not as safe to the user, etc. My work (trash to energy power plant) uses 98% H2SO4 for pH control in the cooling tower. That is NASTY STRONG stuff and is not fun to mess with.

Muriatic is essentially diluted hydrochloric. My work uses a lot of this for de-scaling piping & heat exchangers and for cleaning up lime and ash messes. Much safer than H2SO4. You can get some that has a buffer agent added to it so it is friendlier to your skin if you come in contact with it.

Phosphoric is a weaker acid as well. It is the active ingrediant in "naval jelly" (typically used in auto body work) that is "stops" rust. Actually it converts the rust into a black magnetite that is less prone to further corrosion.

CLR is mor along the lines of "homeowner" grade strength, safer to use, etc.

No matter what you use, you want to use good protective equipment, safety glasses, face shield, goggles are best to prevent eye splashes, etc.

Here's a good link to check out. They talk about a lot of issues & solutions in laymens terms. Not sure of how good of a company they are or how good their products are but they seem pretty straight forward and legit. http://www.woodboilersolutions.com/

Are your pumps ok? Someone last winter posted a similar problem, OWB heating up and cycling a lot but house not getting the heat. They wound up having a bad impeller on the boiler pump, so the boiler side of the HX was not getting sufficient flow (heat) so the house side of the HX was running too cool to heat effectively.

Muriatic is essentially diluted hydrochloric. My work uses a lot of this for de-scaling piping & heat exchangers and for cleaning up lime and ash messes. Much safer than H2SO4. You can get some that has a buffer agent added to it so it is friendlier to your skin if you come in contact with it.

Phosphoric is a weaker acid as well. It is the active ingrediant in "naval jelly" (typically used in auto body work) that is "stops" rust. Actually it converts the rust into a black magnetite that is less prone to further corrosion.

CLR is mor along the lines of "homeowner" grade strength, safer to use, etc.

No matter what you use, you want to use good protective equipment, safety glasses, face shield, goggles are best to prevent eye splashes, etc.

Here's a good link to check out. They talk about a lot of issues & solutions in laymens terms. Not sure of how good of a company they are or how good their products are but they seem pretty straight forward and legit. http://www.woodboilersolutions.com/

Are your pumps ok? Someone last winter posted a similar problem, OWB heating up and cycling a lot but house not getting the heat. They wound up having a bad impeller on the boiler pump, so the boiler side of the HX was not getting sufficient flow (heat) so the house side of the HX was running too cool to heat effectively.

Very important - If you chose to use an acidic cleaner / de-scaler, you need to make sure you flush the system very thoroughly afterward to ensure all the acid (low pH water) is gone, or use another chemical to neutralize to system, then flush, re-fill, re-treat for long term corrosion protection, etc. http://www.woodboilersolutions.com/ mentions this as well.

JTWALL

Member

Seems like vinegar might work as a safer alternative. I have used it before to descale metal/radiators.

Any thoughts?

Any thoughts?

Trex83

Member

Seems like vinegar might work as a safer alternative. I have used it before to descale metal/radiators.

Any thoughts?

Yes, if you get 10% and let it work a couple of ours.

https://www.hearth.com/talk/threads/how-to-get-rid-of-water-corrosion.129244/#post-1741306

Cheers

Bob Rohr

Minister of Fire

Yes, if you get 10% and let it work a couple of ours.

https://www.hearth.com/talk/threads/how-to-get-rid-of-water-corrosion.129244/#post-1741306

Cheers

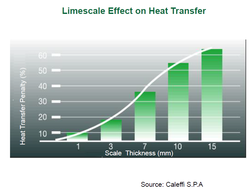

It doesn't take much of a layer of scale to really start hampering HX efficiency. If hard fill water is added on a regular basis, and the furnace is run at bhigh temperatures you will need to de-scale the system more often.

It will take a lot of product to treat that volume of water. If in fact you fill water is hard, above 12 grains or more, you might consider re-filling with DI water after you clean the system.

You can purchase DI water, take some plastic 55 gallon barrels, or rent a DI tank for a day.

Man

Yes, if you get 10% and let it work a couple of ours.

https://www.hearth.com/talk/threads/how-to-get-rid-of-water-corrosion.129244/#post-1741306

Cheers

Did you check the hardness of the fill water. If you have a limescale build up, it is from the water you are filling and adding. Also the hotter you run the system, the more mineral will precipitate and coat the surfaces.

With that much fluid in the Heatmor you will need a bit of cleaner, so a strong acid, diluted as per the directions on the bottle, would be my choice.

Ideally you would refill the system with DI water. You can purchase DI water, take a few plastic barrels and they will fill them. Or in many areas you can rent the DI filter, connect a hose and fill the system.

In my area Culligan will rent the DI filters, or sell the water if you drive to their location.

I would also add conditioners for corrosion protection to the fill water, being an open system it will always take on O2. The inhibitors are to scavange the O2 before it corrodes the ferrous components. Adding inhibitors it will be an ongoing ritual.

Here is a chart showing how a very thin layer of build up hampers HX performance. Both at the OWF and any HXs in the system.

We had a GEO expert present a webinar on Fluid Quality a few years back, here is the DI unit he fills his systems with. The light indicates when it needs to be re-beded.

Attachments

maple1

Minister of Fire

I use regular store vinegar to clean my SS syrup evaporator at the end of the season. About 10 gallons, it has to sit in it for a few days though, it's not fast.

Getting a bit off topic here, but we've found the best thing for that is to just use the last run of sap & let it sour in the pans. Maybe dilute it a bit. It'll be nasty looking when you drain & clean, but the gunk should come off pretty good. We lot ours sit for like 3 months.

- Status

- Not open for further replies.

Similar threads

- Replies

- 10

- Views

- 1K

- Replies

- 8

- Views

- 2K

- Replies

- 9

- Views

- 902

- Replies

- 20

- Views

- 732