Yep, they overfire with the damper open. I find this to be the case within 10 - 20 minutes, no matter how far I shut down the air control. With the damper closed, they're infinitely controllable.

I have three thermometers on each my stove, but I'm an anal-retentive geek, so that may be a wee bit of overkill. In any case, here's my setup, and how I run it:

Therm 1: Condar magnetic dial on top center of top loading door (very fast reacting spot)

Therm 2: Magnetic dial on stovepipe, about 15" above stove collar

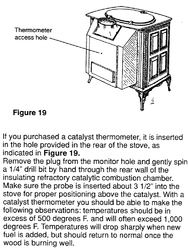

Therm 3: Catalytic probe thermometer. For this, I use a custom high-temp K-type thermocouple probe from Omega, with a cheap Amprobe thermocouple meter. There are better options out there for cat probe thermometers, but this works for me.

On reload:

1. Open bypass, rake coals, load stove.

2. Leave one front door cracked up to a minute or three, if necessary, never longer than it takes for load to light.

3. Close and latch doors, set iPhone timer for 5 - 8 minutes, depending on size of load and how vigorously it lit up.

4. When timer goes off, check stove top and stove pipe temp. If both are > 500F, and load looks well-charred, close bypass damper. If stovepipe is getting > 600F, and stove top is still cool or wood isn't well charred, then lower primary air and re-set iPhone timer for 3 minutes.

5. Check again, and adjust air as necessary to keep stovepipe from getting too hot, until stovetop is > 500F and load is well-charred.

6. Close bypass damper and set iPhone timer for 5 minutes.

7. When timer goes off, verify that cat temp is > 700F. If so, lower air to 1/2, and reset timer for 5 minutes. If not, wait until it is, then lower air to 1/2, and reset timer for 5 minutes.

8. When timer goes off, lower air to 1/4, and reset timer for 5 minutes.

9. When timer goes off, lower air to final setting. This "final setting" is full-closed on my stove with the 27 foot chimney, but maybe on the "minus" symbol for my stove with the shorter chimney. I find that going full-closed on the stove with the shorter chimney results in some back-puffing, unless temps are screamingly cold outside.

If I were strapped for cash, I would probably skip the stovetop thermo before skipping on the cat thermo. However, using mechanical thermometers for each, you're probably looking at under $100 for all three. You can use a small mirror to read a mechanical probe thermo in the back of the stove, in a pinch. There are pre-packaged electronic cat probe thermometers, but they usually cost more than the mechanicals.[/quote

Yeh, actually condar mentioned a rather expensive option that went in the back of stove im prety sure they said in the 150 dollar range . ill start out using cheaper version . any suggestions on brand , i read on condars site they were like the pioneers of the thermostats i thought i read first magnet therm . i could be wrong with out scanning back to thier site . Ill start with a magnet type and as we get into the colder weather ill try and get as you describe @ least two one on pipe and one on cover . then next year . i could buy a probe type . if you can post a pic of these , set ups you have might help me understand where that cat probe one goes and how it mounts in there . im clueless . thats why i thought mag type to at least keep my temps down . So do you think a normal burn temp woulld be 500 to 600 or what temp do you say woe back off jack on the magnet type ? so ill know i could cause damage to internals . i thought these stoves went way up over 600 and still safe but i guess im wrong ! Should be interesting to see how my stove operates after all new parts and gaskets . and using a thermostat . for first time in 19 years ! do you use a blower to disperse the heat from stove ?

They told me to use it, so I use it. I figure someone must have had a good reason to add this expensive silly little piece to the design, even if I don't understand what it is.

They told me to use it, so I use it. I figure someone must have had a good reason to add this expensive silly little piece to the design, even if I don't understand what it is.