Looking for any tips/tricks/advice for this project.

What we are working with:I'm the 3rd owner of this old house, the last one was a mason and installed a massive stone fireplace in the addition he tacked on to the house (bringing the total square footage to 1200 sq ft). One of the first things we did was add in my Jotul C550 Rockland with a liner. It's been heating us like a champ for a few years now. Sadly, in spite of the fireplace being massive and dominating the living room - it feels a bit... naked. Here is a shot from one of our Christmas's:

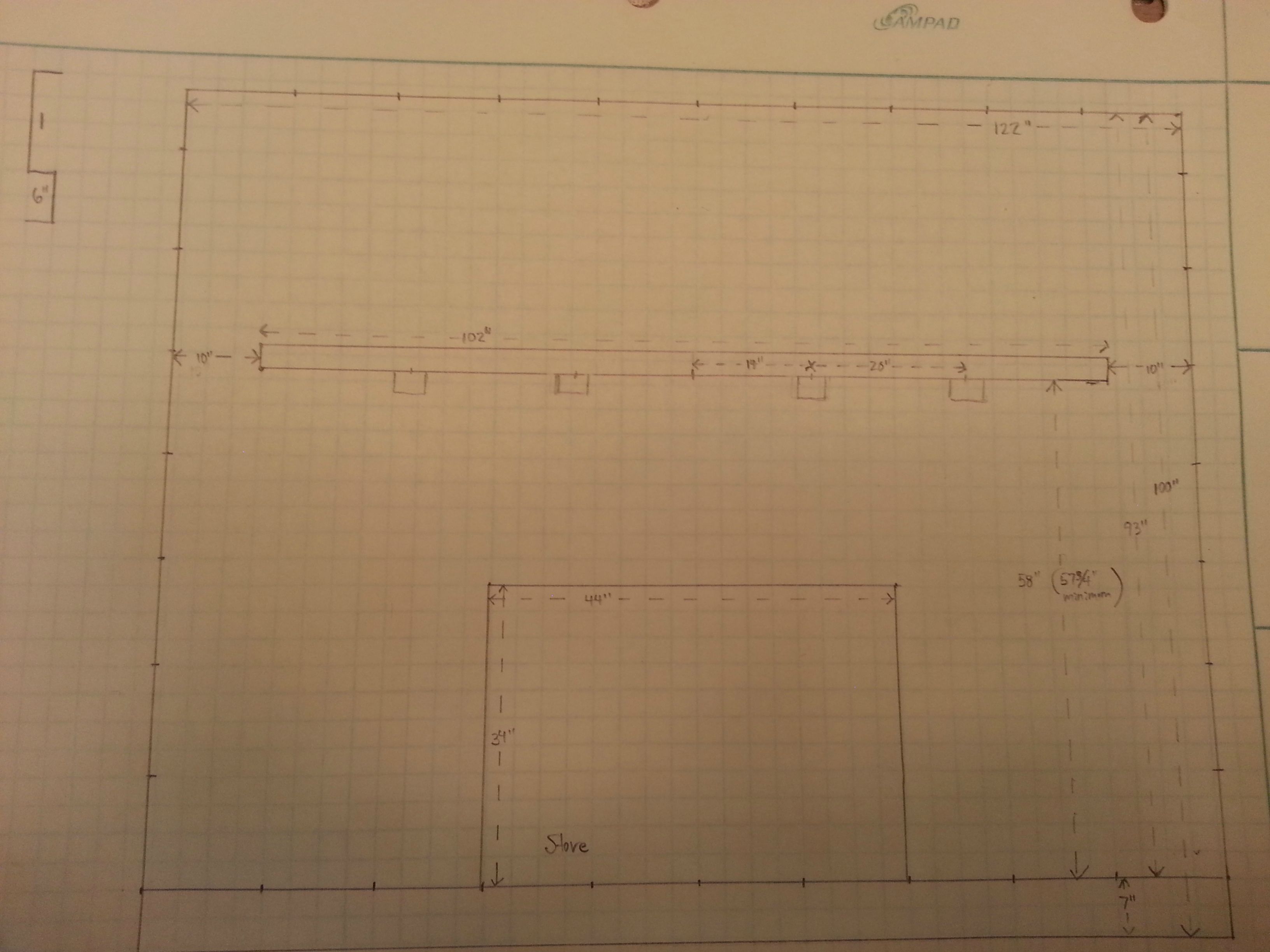

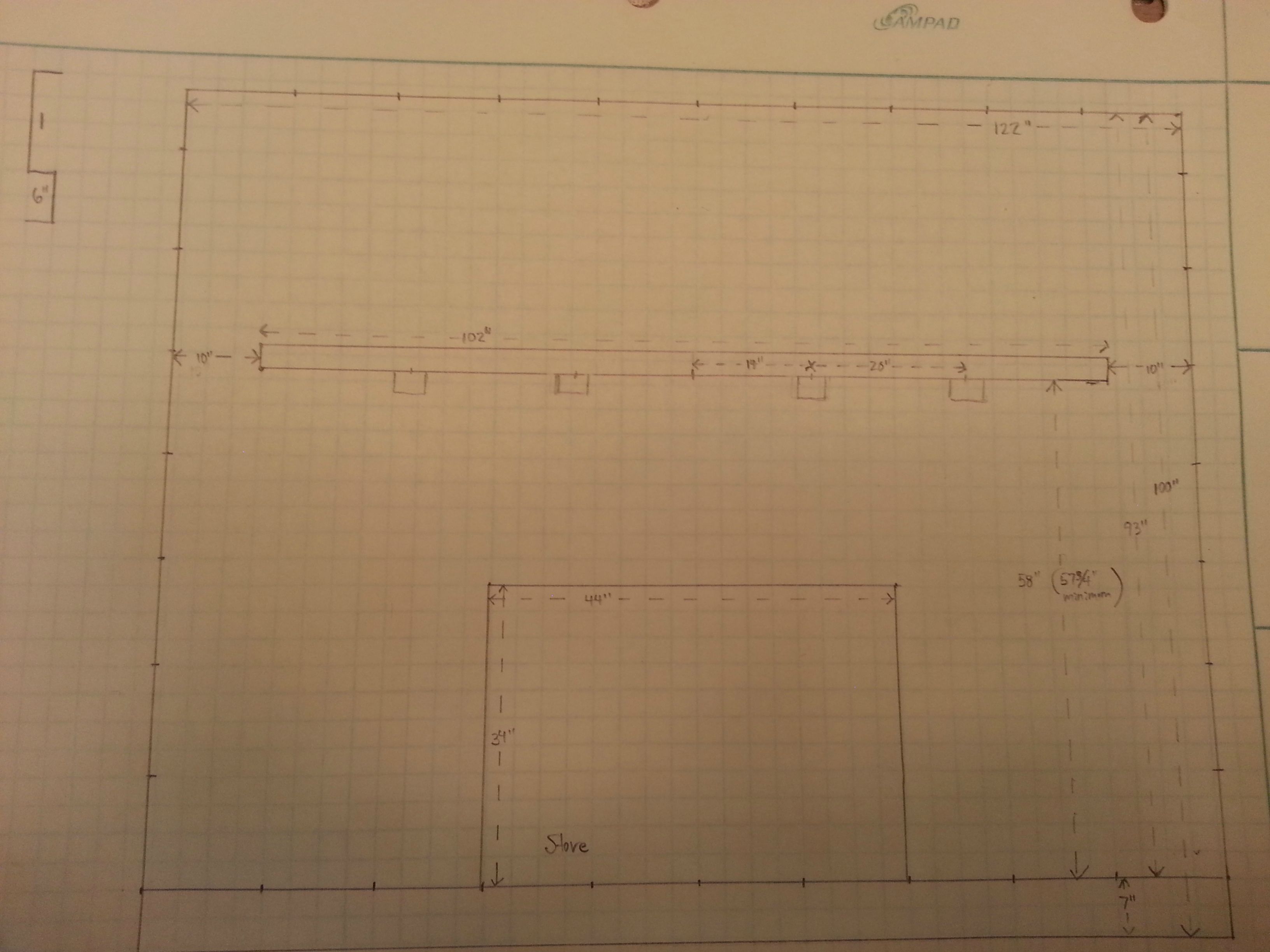

The stone work is 93" high (reaches the ceiling) and about 122" wide. We want a mantel.

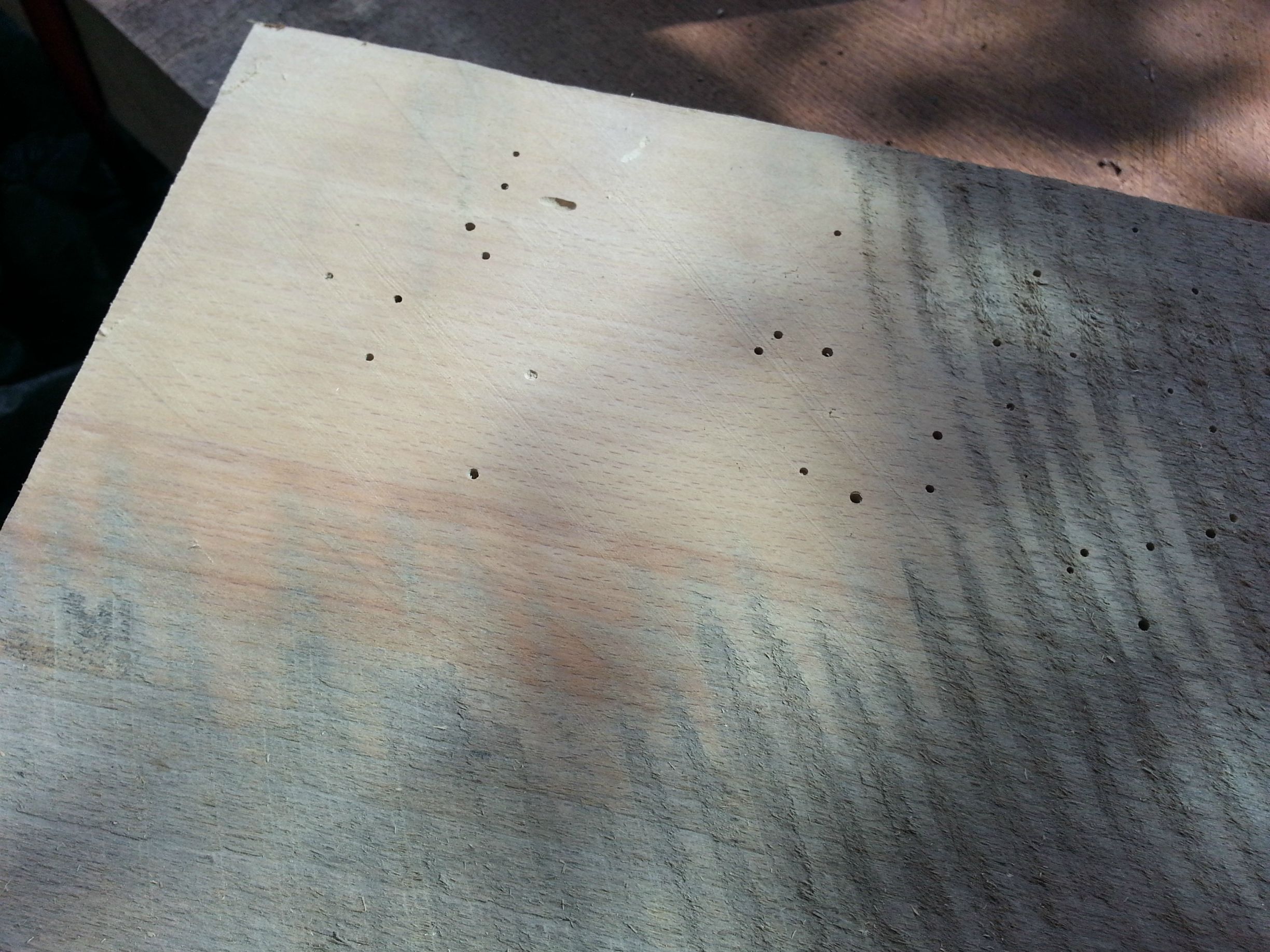

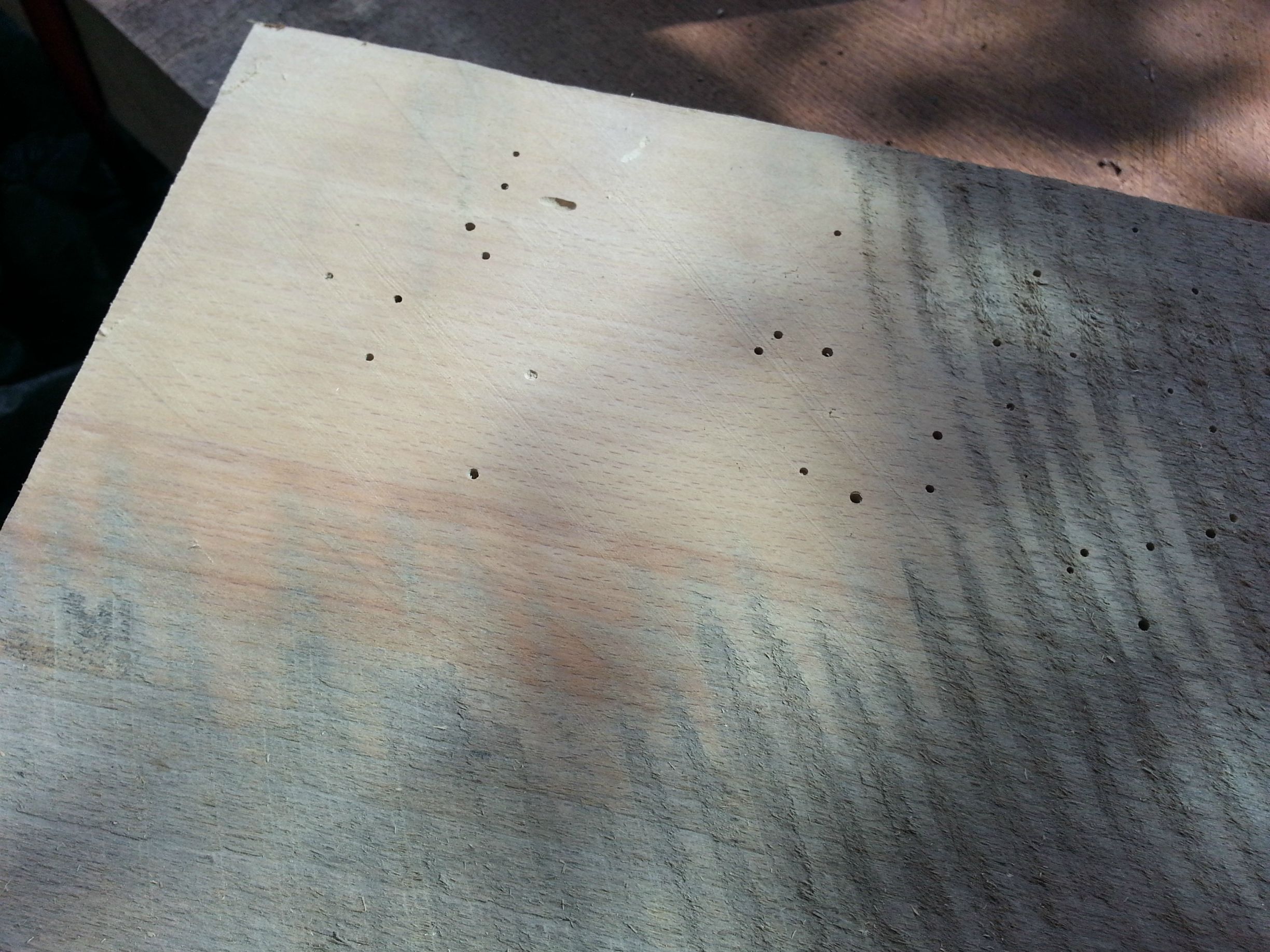

I've since procured a rough cut board that is about 3" x 12" x 14'. It had been sitting in a local barn since 1955 when it came down in a hurricane and it was a screaming deal. Not sure what it is exactly, possibly poplar or elm? There is also lots of ash around here but I don't think it's that. It's been bit up a little by powder post beetles but I can live with imperfections since I want a rustic look anyways and I like wood that has a little history.

The tentative plan:

I'm going to plane down the board and chop it down to 102", to make a floating shelf style mantel with a 10" gap on either end. I'll use some of the extra to make some faux supports (4 of them) spaced across the bottom, with the end grain facing out so they look as if they are actually sunk into the masonry.

Once I have all the wood cut and put together I'm planning on "tenting" off the area (and all the door ways too) with plastic and making an exhaust to outside with some fans and using an angle grinder to grind down the stones where the mantel will attach to make it flat. I had considered trying to scribe the back of the wood - and while the grinding will be wayyyyy messier I think it'll be faster and less overall work since then I'll have two flat surfaces to attach to each-other.

Don't mind the little fairy walking by in my shot... she wanders around anytime I'm working on a project.

Once I have two prepared surfaces I'm going to use a hammer drill to make holes somewhere between 8-12" into the masonry and drill holes 8" into the back of the mantel to match them. I'm planning on having about 8 sets of matching holes. I'll cut lengths of iron pipe that fit into the holes and after vacuuming and and ensuring the holes are cleaned out will epoxy the pipes into the masonry.

After the epoxy sets I'll put the mantel up. I plan to tap into at least two of the holes in the mantel from the top so that I can have a small metal pin drop in to keep the mantel from falling off the wall (and I'll hide those with some plugs).

Once everything is up and looking good I'll experiment on some of the scraps to see what, if any, kind of finish I'll apply. I like darker looking wood and I might try aging or lightly distressing the wood, too.

Any ideas or critiques would be welcomed. Of course once I'm done more pics will follow but I'm determined that we'll finally have something better than nails to hang our stockings from this year!

What we are working with:I'm the 3rd owner of this old house, the last one was a mason and installed a massive stone fireplace in the addition he tacked on to the house (bringing the total square footage to 1200 sq ft). One of the first things we did was add in my Jotul C550 Rockland with a liner. It's been heating us like a champ for a few years now. Sadly, in spite of the fireplace being massive and dominating the living room - it feels a bit... naked. Here is a shot from one of our Christmas's:

The stone work is 93" high (reaches the ceiling) and about 122" wide. We want a mantel.

I've since procured a rough cut board that is about 3" x 12" x 14'. It had been sitting in a local barn since 1955 when it came down in a hurricane and it was a screaming deal. Not sure what it is exactly, possibly poplar or elm? There is also lots of ash around here but I don't think it's that. It's been bit up a little by powder post beetles but I can live with imperfections since I want a rustic look anyways and I like wood that has a little history.

The tentative plan:

I'm going to plane down the board and chop it down to 102", to make a floating shelf style mantel with a 10" gap on either end. I'll use some of the extra to make some faux supports (4 of them) spaced across the bottom, with the end grain facing out so they look as if they are actually sunk into the masonry.

Once I have all the wood cut and put together I'm planning on "tenting" off the area (and all the door ways too) with plastic and making an exhaust to outside with some fans and using an angle grinder to grind down the stones where the mantel will attach to make it flat. I had considered trying to scribe the back of the wood - and while the grinding will be wayyyyy messier I think it'll be faster and less overall work since then I'll have two flat surfaces to attach to each-other.

Don't mind the little fairy walking by in my shot... she wanders around anytime I'm working on a project.

Once I have two prepared surfaces I'm going to use a hammer drill to make holes somewhere between 8-12" into the masonry and drill holes 8" into the back of the mantel to match them. I'm planning on having about 8 sets of matching holes. I'll cut lengths of iron pipe that fit into the holes and after vacuuming and and ensuring the holes are cleaned out will epoxy the pipes into the masonry.

After the epoxy sets I'll put the mantel up. I plan to tap into at least two of the holes in the mantel from the top so that I can have a small metal pin drop in to keep the mantel from falling off the wall (and I'll hide those with some plugs).

Once everything is up and looking good I'll experiment on some of the scraps to see what, if any, kind of finish I'll apply. I like darker looking wood and I might try aging or lightly distressing the wood, too.

Any ideas or critiques would be welcomed. Of course once I'm done more pics will follow but I'm determined that we'll finally have something better than nails to hang our stockings from this year!