as long as I've been on this site I should know this stuff by now.but I brought home my solo + MK II 60kw used boiler. Looks very good. but also in my travels today I found a gentleman that has a thousand gallon propane tank and will weld whatever size fittings in it for me. Good price too. I need 10%expansion tanks also? Which would be 100gals of expansion? Correct? How about location of inlet and outlet on propane tank? Is it better to have 1000 gal tank horizontal or vertical? I can do either In my space.

1000 gals press storage

- Thread starter flyingcow

- Start date

-

Active since 1995, Hearth.com is THE place on the internet for free information and advice about wood stoves, pellet stoves and other energy saving equipment.

We strive to provide opinions, articles, discussions and history related to Hearth Products and in a more general sense, energy issues.

We promote the EFFICIENT, RESPONSIBLE, CLEAN and SAFE use of all fuels, whether renewable or fossil.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

- Status

- Not open for further replies.

BoiledOver

Minister of Fire

5% for expansion is good...... 4.3% is the maximum expansion from 33F to 210F

If you have many cast iron rads and huge lengths of pipe then you would need to figure the added volume.

If you have many cast iron rads and huge lengths of pipe then you would need to figure the added volume.

Mike Fromme

Burning Hunk

If you are using diaphragm expansion tanks remember the acceptance volume is what matters.

Coal Reaper

Minister of Fire

Vertical! Port in the top with diffuser and bottom one a few inches up.

Clarkbug

Minister of Fire

as long as I've been on this site I should know this stuff by now.but I brought home my solo + MK II 60kw used boiler. Looks very good. but also in my travels today I found a gentleman that has a thousand gallon propane tank and will weld whatever size fittings in it for me. Good price too. I need 10%expansion tanks also? Which would be 100gals of expansion? Correct? How about location of inlet and outlet on propane tank? Is it better to have 1000 gal tank horizontal or vertical? I can do either In my space.

As coal reaper said, vertical will be better for stratification purposes, so you can really steal that last little bit of heat out of the tanks, or also keep your boiler at full heat transfer by pulling cold water. Just be sure to figure out a good way to secure it! Thats a LOT of weight that could get sideways in a hurry and do a lot of damage.

As coal reaper said, vertical will be better for stratification purposes, so you can really steal that last little bit of heat out of the tanks, or also keep your boiler at full heat transfer by pulling cold water. Just be sure to figure out a good way to secure it! Thats a LOT of weight that could get sideways in a hurry and do a lot of damage.

vertical..as the congress agreed on is the way to go but how thick and what quality is your slab ?????

8300#+1700# stacked is quite the dangerous behemoth

are u using a ring base??

scott

Last edited:

as long as I've been on this site I should know this stuff by now.but I brought home my solo + MK II 60kw used boiler. Looks very good. but also in my travels today I found a gentleman that has a thousand gallon propane tank and will weld whatever size fittings in it for me. Good price too. I need 10%expansion tanks also? Which would be 100gals of expansion? Correct? How about location of inlet and outlet on propane tank? Is it better to have 1000 gal tank horizontal or vertical? I can do either In my space.

use weldolet fittings...seen structural failures with some other brands on the market ...

Bob Rohr

Minister of Fire

If you are using diaphragm expansion tanks remember the acceptance volume is what matters.

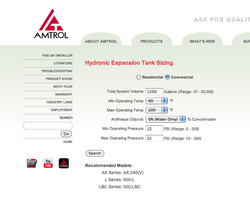

I would use a bladder type expansion tank. Also use the free sizer program at Amtrol.

Looks like a 132 gallon tank, 46 acceptance. It could be multiple smaller tanks, sometimes works out less $$

Attachments

5% for expansion is good...... 4.3% is the maximum expansion from 33F to 210F

If you have many cast iron rads and huge lengths of pipe then you would need to figure the added volume.

I will have 4 "modine" type heaters. These will be in the corners of a 35x75 truck garage.

Thanks

vertical..as the congress agreed on is the way to go but how thick and what quality is your slab ?????

8300#+1700# stacked is quite the dangerous behemoth

are u using a ring base??

scott

The tank will be from a fabricator, so if I do this, he will fabricate a base. This is on a 6 inch slab.

I would use a bladder type expansion tank. Also use the free sizer program at Amtrol.

Looks like a 132 gallon tank, 46 acceptance. It could be multiple smaller tanks, sometimes works out less $$

Thanks will follow your suggestions.

Much appreciated.

NE WOOD BURNER

Minister of Fire

- Dec 30, 2012

- 754

The tank will be from a fabricator, so if I do this, he will fabricate a base. This is on a 6 inch slab.

should be all good, with proper rebar and good cure you should be at 10,000psi to 12,000 psi

me being insane...I would put down a square of insulation and then a steel plate as a spreader....not needed but helps me sleep better....

pix, pix,pix

good luck brother

Scott

Chris Hoskin

TarmSalesGuy

I meant to say new nozzle. That ole' girl was heavy. It was 110 miles away. I didn't want to haul my 9000lb tractor all the way up and back. I knew I could haul the boiler on my pickup easy. Made a few calls, found a guy right next door....."oh yeah I can pick that easy with my tractor." Wasn't easy, damn near dropped it. But we got it. Scratched our heads a few times. Basically he started lifting and two of us helped lift by pulling on the forks.....its a wonder we didn't get hurt. But its home.

The tank will be from a fabricator, so if I do this, he will fabricate a base. This is on a 6 inch slab.

Tell him to weld an old solid rim on it...

and make it a wide one..oh and make sure he cuts an access hole on the side of the base/rim, so you can pipe out a bottom clean out pipe/drain..so you can flush out the gunk from the bottom of the tanks ...

scott

Last edited:

Tennman

Minister of Fire

FC, I bought Sch 40, 1 1/2" nipples ~14" or 16" long and cut them in half for our tank ports. Wanted to avoid a threaded joint under the foam so we have a 1 1/2" NPT male outside the foam surface. We are ceiling height limited for our (2) vertical 500gal tanks, so the bottom dome is only ~2=3" off the floor. We cut a rather long elliptical hole so the bottom port is nearly flush with the bottom of the tank and serves as a drain and boiler return port. Even after this the tanks had to be positioned between the barn rafters due to added height with the foam. I chose to weld four 3"x1/4" angle legs vs the ring base... personal preference. If you go weld flanges Weldolet brand is the best. I got some "NPT weld flanges" from McMaster and they were some cheap pressed steel crap from China. Best wishes... and whatever you do soapy water leak check. Of the 10 ports, we had ~3 pin hole leaks.

Well, got ahead of myself a bit. Vertical is not gonna work. Horizontal will have to do. But thanks for the thoughts on going vertical.

Is 4 inches of spray on foam enough? R-28-ish?

Is 4 inches of spray on foam enough? R-28-ish?

NE WOOD BURNER

Minister of Fire

- Dec 30, 2012

- 754

Are you short of 16'?Vertical is not gonna work

Well, got ahead of myself a bit. Vertical is not gonna work. Horizontal will have to do. But thanks for the thoughts on going vertical.

Is 4 inches of spray on foam enough? R-28-ish?

WHAT????????

GIVING UP ON VERTICAL JUST LIKE THAT?

take out a couple of joists and reinforce around them..

cut a hole ....and build a sofa platform over the tank....toasty....

oh man

jebatty

Minister of Fire

Vertical is not the sole answer in all applications. OP is using 4 "modine" type unit heaters. These typically take quite hot water, 140-180F, and return water at a 20F temp drop; also often quite high flow. If any of this is true, this storage tank will see lots of mixing because very warm water is being returned.

The challenge, whether vertical or horizontal, will be two-fold: 1) porting to insure the hottest water is available to the maximum extent on the supply to the unit heaters, and 2) somewhat limited usefulness of storage if return temperatures are quite high which may result in the need to fire the boiler more frequently to insure sufficient hot water is available to the unit heaters.

The challenge, whether vertical or horizontal, will be two-fold: 1) porting to insure the hottest water is available to the maximum extent on the supply to the unit heaters, and 2) somewhat limited usefulness of storage if return temperatures are quite high which may result in the need to fire the boiler more frequently to insure sufficient hot water is available to the unit heaters.

maple1

Minister of Fire

Do you know what you will be pumping the heaters with?

If you can do it with a variable speep Alpha, you could also vary flows to widen your delta-T and lower your return temps and reduce mixing. Maybe?

If you can do it with a variable speep Alpha, you could also vary flows to widen your delta-T and lower your return temps and reduce mixing. Maybe?

Right now this isn't even drawn out on paper yet. I'm thinking of 4 modine type units, may go with two, who knows. I think i'll get a more balanced/even room temps with 4. Picture 35x75(16ft ceiling) two bay truck garage with at least one, sometimes two 65ft long trucks parked in there, only 12 hours of the day though. Plan on 45f room temp when not occupied by a human. When I'm in there I'll go to maybe 60/65f ? I plan on having the boiler plumbed up similar like my house, which is done per Tarms diagrams. The system will have a T-valve(I think termovar 1) so that when the unit heaters are calling for heat, that will be priority over heating storage.

And yes, i agree jebatty, in the absence of boiler running, storage will loose btu's pretty quickly. Not big deal if it drops below temp in the garage. What i need to learn is location of inlet and outlet into propane tank. Didn't know much about it, other than returning wtaer to tank it should be on the bottom. Would like advice on where to locate inlet and outlet.

I'll be in and out of garage, with truck, basically a 12 hour schedule. I usually leave with truck at 4am and return 3 to 4pm. Usually the garage will stay empty in between those times. If i get home a 3pm and storage is depleted, i will build a fire. If i need to do a few hours of work at that time, I will crank up t-stats and go up to the house for lunch or whatever. I should have 165f+ water rolling thru modines in an hour. 185f+ water shortly after that. With the 4 modines, shouldn't take long to make it toasty in there. In years past I used an oil fired unit heater for heat when I was in garage. It was shut off. most of the time when i wasn't there. Burned 200 to 250 gals a yr. But i want to maintain garage at 45f all the time.

With your guy's input, this should work quite well. I bought that Tarm solo 60kw boiler for $1700, or I should say i kinda stole it. A welder/fabricator, who has done these propane tank conversion before, has given me a price of $950 for tank, all fittings in place. Also he will pressure test it too. I will hire to have everything installed. But that will be with my BIL, he installed the system in my house. Very capable and will treat me fair on price.

What i'm finding out, is with the advancement of pellet boilers, you can find some decent deals on used wood boilers. People lost the interest in handling cord wood, which I feel their pain sometimes. Just be patient and you can find a boiler, maybe.

Maple, I'll look inti variable speed units, but I have a grundofoss 3 speed on my house system, once i found the right setting, i haven't touched it again.

And yes, i agree jebatty, in the absence of boiler running, storage will loose btu's pretty quickly. Not big deal if it drops below temp in the garage. What i need to learn is location of inlet and outlet into propane tank. Didn't know much about it, other than returning wtaer to tank it should be on the bottom. Would like advice on where to locate inlet and outlet.

I'll be in and out of garage, with truck, basically a 12 hour schedule. I usually leave with truck at 4am and return 3 to 4pm. Usually the garage will stay empty in between those times. If i get home a 3pm and storage is depleted, i will build a fire. If i need to do a few hours of work at that time, I will crank up t-stats and go up to the house for lunch or whatever. I should have 165f+ water rolling thru modines in an hour. 185f+ water shortly after that. With the 4 modines, shouldn't take long to make it toasty in there. In years past I used an oil fired unit heater for heat when I was in garage. It was shut off. most of the time when i wasn't there. Burned 200 to 250 gals a yr. But i want to maintain garage at 45f all the time.

With your guy's input, this should work quite well. I bought that Tarm solo 60kw boiler for $1700, or I should say i kinda stole it. A welder/fabricator, who has done these propane tank conversion before, has given me a price of $950 for tank, all fittings in place. Also he will pressure test it too. I will hire to have everything installed. But that will be with my BIL, he installed the system in my house. Very capable and will treat me fair on price.

What i'm finding out, is with the advancement of pellet boilers, you can find some decent deals on used wood boilers. People lost the interest in handling cord wood, which I feel their pain sometimes. Just be patient and you can find a boiler, maybe.

Maple, I'll look inti variable speed units, but I have a grundofoss 3 speed on my house system, once i found the right setting, i haven't touched it again.

goosegunner

Minister of Fire

Vertical is not the sole answer in all applications. OP is using 4 "modine" type unit heaters. These typically take quite hot water, 140-180F, and return water at a 20F temp drop; also often quite high flow. If any of this is true, this storage tank will see lots of mixing because very warm water is being returned.

The challenge, whether vertical or horizontal, will be two-fold: 1) porting to insure the hottest water is available to the maximum extent on the supply to the unit heaters, and 2) somewhat limited usefulness of storage if return temperatures are quite high which may result in the need to fire the boiler more frequently to insure sufficient hot water is available to the unit heaters.

I was going to post similar a few days ago but couldn't quite get the wording right. I have 1000 gallon tank horizontal. It works well but I sometimes wonder if I am mixing too much. My tank stratifies well but at some point with my forced air exchanger the return water is higher than the bottom of the tank temp.

Some day I would like to add a small buffer tank in my house to set up my DHW. I could also use it to deplete the water down to a determined temp before sending it back to the 1000 gallon storage tank. The big question is it worth the extra complexity of the controls. Running off storage seems to be a moving target. When your supply temps range from 190 down to 140 it makes my head spin trying to figure out the best method with a buffer tank.

I honestly believe that a vertical tank could cause more mixing than a horizontal tank when using forced air exchangers if you do not set up to deplete temperature before sending it back to storage.

gg

- Status

- Not open for further replies.

Similar threads

- Replies

- 34

- Views

- 6K

- Replies

- 19

- Views

- 2K

- Replies

- 75

- Views

- 6K

- Replies

- 22

- Views

- 2K