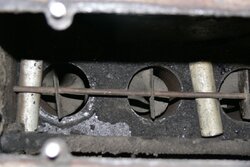

I'm in the process of cleaning a biomass 40 that I bought used in the spring. I have the turbulators out now and I was wanted to know if there are any hints to putting them back easily. Do I assemble the turbs on the cross member and drop it in or one at a time? I took them out one at a time but they didn't fall down the exchanger tubes because it was never cleaned. Also what should I use for a gasket on the lower side cover with 4 bolts? New Horizons doesn't sell one and said use hi temp silicone no gasket. Seems like the ceramic gasket is important to me.

cleaning biomass

- Thread starter davem3261

- Start date

-

Active since 1995, Hearth.com is THE place on the internet for free information and advice about wood stoves, pellet stoves and other energy saving equipment.

We strive to provide opinions, articles, discussions and history related to Hearth Products and in a more general sense, energy issues.

We promote the EFFICIENT, RESPONSIBLE, CLEAN and SAFE use of all fuels, whether renewable or fossil.