An infrared thermometer is a lot handier as long as one can get a beam on the actual stove top. Inserts and stoves that have a fully convective top are sometimes more challenging in this regard. The other advantage of using the Auber unit with a thermocouple is that it has high/low temp alarms you can set. This is very useful, particularly on startups and reloads. Busy people tend to get involved and forget to turn the air down if they are not watching the time. I like to carry a timer with me (cell phone works well) and set it to 7 or 10 minutes.

New Guy; forced into burning for primary heat.

- Thread starter newburner

- Start date

-

Active since 1995, Hearth.com is THE place on the internet for free information and advice about wood stoves, pellet stoves and other energy saving equipment.

We strive to provide opinions, articles, discussions and history related to Hearth Products and in a more general sense, energy issues.

We promote the EFFICIENT, RESPONSIBLE, CLEAN and SAFE use of all fuels, whether renewable or fossil.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

- Status

- Not open for further replies.

Latest test fire info:

Last night temps were mid 40's. Started the fire at 7:30pm using 3 bio bricks and added 2 splits a half hour later.

Thermo still peaked at only 400° after an hour so I decided to put it in the box just to see. Once in the box, temps peaked at 700°. So I will assume that the real stove top temp was ~550?

By 9:30pm the flames were almost gone. 10:30 saw a red hot coal bed. Temps were still ~550° and the fan was blowing plenty of heat.

Unfortunately, according to my notes on previous tests, I did not see ANY increase in either temp (measured outside the box) or longevity of flames using the bio bricks. I will increase the number of bricks used on the next test. I really want to get this right and feel confident about what I'm doing before the cold weather sets in.

3 BioBricks is a very small fire. I burnt 13-15 at a time. You must follow their instructions to do this!

http://originalbiobricks.com/howtoburn

https://www.hearth.com/talk/wiki/biobricks/

3 BioBricks is a very small fire.

Agreed and I knew it would be. I was following the advice of others to start small until I am familiar with how they burn.

Would you think I'd be better served by skipping the intermediate step and going to a box full? From what I've seen from 3, I don't expect to be overwhelmed with 6.

There is a point where multiple bricks will combust too quickly if they are not stacked loosely and incorrectly. I would follow the mfg instructions if the intent is burn a sustained heating fire.

HotCoals

Minister of Fire

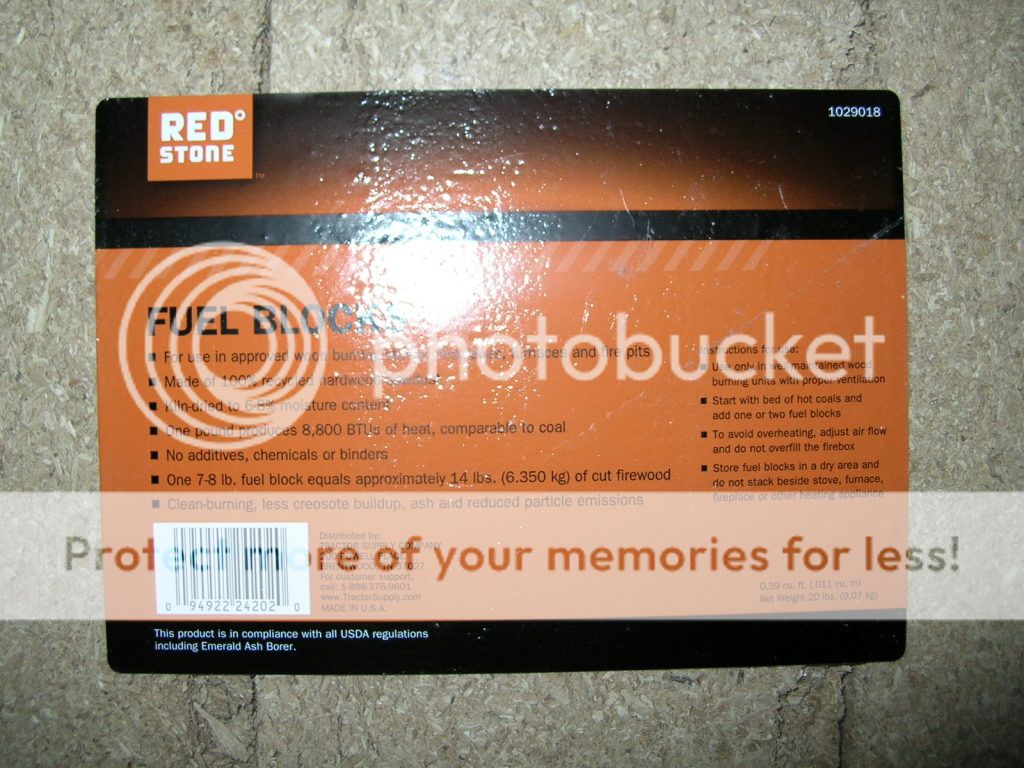

I just bought a ton of those at TSC myself. I wanted Eco Brick brand but the manager said they are only carrying their Redstone bricks now. She claimed that they are made by Eco Brick, just larger - three in a pack instead of six.

Thats what I was told also.

Did you notice on the package it says 8,800 btu's per pound but yet it also says same output as coal . They are a little mixed up..lol.

They also say at their site that a ton = a cord of hard wood,I have a hard time buying into that more so know that I put a ton in my trailer where a face cord of wood fits.

They also claim on the label that7-8 lbs of brick= 14 lbs of wood. I question that also but will know more when I get serious when the cold gets here.

cookin2night

Member

Those laser thermometers are pretty awesome. I used my father in laws the other day. Checked the floor vs. Ceiling of every room. Checked the windows. Checked the doors. Very good for finding heat loss. I'm going out to buy one this weekend.An infrared thermometer is a lot handier as long as one can get a beam on the actual stove top. Inserts and stoves that have a fully convective top are sometimes more challenging in this regard. The other advantage of using the Auber unit with a thermocouple is that it has high/low temp alarms you can set. This is very useful, particularly on startups and reloads. Busy people tend to get involved and forget to turn the air down if they are not watching the time. I like to carry a timer with me (cell phone works well) and set it to 7 or 10 minutes.

cookin2night

Member

I would say that a laser thermometer might be the best tool one could carry when trying to make your home as warn as possible.

ddahlgen,

Yes, 3 was pretty useless. I was going on advice to start small. I'll ramp it up next time. I'm thinking of a tight layer of 6 on the bottom topped with a split or two on top.

I am able to put 14 in that little box but I can't afford that unless they burn 8-10 hours. I don't see that happening though.

Tight is not your friend you need surface area to have fire and heat. Ever see cordwood burn from the inside out? Didn't think so plus they need room to swell when burning or just turn to coals at best and no heat. All those that say don't put in more than a few and pack them tight are just a bunch of nervous old women afraid to get a good fire in the stove and get it hot. I have no idea what the problem is with a stovetop at 650 to 700 is. Maybe my Avalon Pendleton while small is very robust in construction. Maybe it is years of working on turbocharged racing engines that if the exhaust lights off to 1500 to 1700 and bright red barely catches my attention any more 700 seems very tame to be honest well within the ability or steel to deal with it unless very poorly designed. The little Pendleton uses firebrick for the baffle so not going to warp that or crack it either. 700 on the top is so far from hurting steel even the cheapest 1018 low carbon steel that is silly to worry about.

hoot

Burning Hunk

Those laser thermometers are pretty awesome. I used my father in laws the other day. Checked the floor vs. Ceiling of every room. Checked the windows. Checked the doors. Very good for finding heat loss. I'm going out to buy one this weekend.

I used a laser thermometer in the beginning. Problem is there is a cast iron grate on top and it's not easy to get a reading through the slots. That is why I finally went with the thermocouple.

HotCoals

Minister of Fire

Right now I have the thought that a small cat stove might work better for heat bricks better then a large one.

cookin2night

Member

I have a small cat stove in addition to an insert, vermont castings dutch west. How can you tell when it's putting out efficient heat? Is it partly feel?Right now I have the thought that a small cat stove might work better for heat bricks better then a large one.

About 3 hours in and still ~600°. Substantial flames and a mound of glowing coals. I should see 4 hours before the last of the flames go out.

HotCoals

Minister of Fire

HotCoals

Minister of Fire

Yea I increased it to 50% right before I took that pic.

Thought maybe.

In the dead of winter I can get 12 hours easy off my BK with a 2/3 load of hardwood. Then if I open the air way up I can get another 3 hours of good heat plus that helps with burning the coals down. Sometimes I even sprinkle some pellets onto the coals to get some hot flame during that process.Two or three cup fulls.

I think 12 hours out of my little stove would be a pipe dream but, are you saying that I can increase the burn time 25% by opening up the air at the end of the burn?

HotCoals

Minister of Fire

I think 12 hours out of my little stove would be a pipe dream but, are you saying that I can increase the burn time 25% by opening up the air at the end of the burn?

I'm just saying that sometimes I can. Your millage may very lol. Cheers!

Comparing a big BK cat to a small Century is apples to oranges. They are two different animals. The mileage will almost always vary.

HotCoals

Minister of Fire

True but maybe he will increase his burn time by maybe up to 25% ...thinking about it 4 extra hours with the air all the way may be a little high..but I know I can get 3 extra hours most times. I also may stir up things with the poker and add some pellets also once or twice during that time.Comparing a big BK cat to a small Century is apples to oranges. They are two different animals. The mileage will almost always vary.

Update:

Well my wood supplier has vanished after 2 cords. I guess he is either out of wood or he no longer wants to sell me wood for $175/cord. Im not sure which since he wont return my calls. Either way, I'm guessing I'm about 2 cords short of what I "think" I'll need to get through the winter. Since everyone else around here is selling cords for $250 or more (and you never know what you're going to get) I guess we will be redirecting our financial resources to bio bricks from here on out.

So as it stands right now, I have 2 cord and a half ton of bricks. I'll be getting more bricks each week until I can't get any more.

Well my wood supplier has vanished after 2 cords. I guess he is either out of wood or he no longer wants to sell me wood for $175/cord. Im not sure which since he wont return my calls. Either way, I'm guessing I'm about 2 cords short of what I "think" I'll need to get through the winter. Since everyone else around here is selling cords for $250 or more (and you never know what you're going to get) I guess we will be redirecting our financial resources to bio bricks from here on out.

So as it stands right now, I have 2 cord and a half ton of bricks. I'll be getting more bricks each week until I can't get any more.

NewStoveGuy

New Member

Update:

Well my wood supplier has vanished after 2 cords. I guess he is either out of wood or he no longer wants to sell me wood for $175/cord. Im not sure which since he wont return my calls. Either way, I'm guessing I'm about 2 cords short of what I "think" I'll need to get through the winter. Since everyone else around here is selling cords for $250 or more (and you never know what you're going to get) I guess we will be redirecting our financial resources to bio bricks from here on out.

So as it stands right now, I have 2 cord and a half ton of bricks. I'll be getting more bricks each week until I can't get any more.

I'm in the same boat. My guy vanished after selling me 2 cords @ $100/cord for 6mo-1yr oak, even though I paid him for another half cord that I haven't received. Can't complain too much given the price and the fact that 1.5 cords of the 2 was metering at 20-25% two months ago. I figure I have 3.25 laid up with the scrounging I've done but 1 of those is definitely 3 handle on the meter. Have been thinking I'd need 2.5-3 for the season so I'm still short. There's plenty of "seasoned" wood on CL near me for $200-275/cord, but I don't need any more wet wood.

It helps to get a year or two ahead. If buying. April 1st should be the cut off date. Folks buying now are out of luck unless they have a kiln dried wood seller nearby. If buying now, consider getting ash if available and avoid oak and hickory. Truly seasoned pine, fir or hemlock is ok too. But before letting them dump it off the truck take some random splits off and resplit them, then test for moisture before accepting the load.

It helps to get a year or two ahead.

Believe me, I'm trying. Very difficult to do in first year. Especially on a tight budget.

- Status

- Not open for further replies.

Similar threads

- Replies

- 3

- Views

- 620

- Replies

- 12

- Views

- 473

- Replies

- 17

- Views

- 1K

- Replies

- 8

- Views

- 841