Just seeing if anyone has any pointers or opinions on things that could help me this winter. I don't care about your EPA stove, I prefer old school.

Shop Stove:

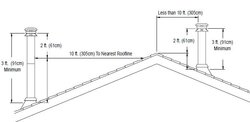

Scandia 308, 8" flue through roof, sand bed in bottom of stove, has secondary damper

Small basement stove:

Boxwood, 6" flue, has fire bricks installed

Main home stove:

Old Mill 80, 6" flue, fire bricked

Will be running mostly Oak, tree was taken down late winter, immediately sectioned, and split. Have a feeling it's still going to be a little green come November... I am taking some of the drier pieces and splitting them thinner, and stacking inside my wood shed. Will have a backup load of seasoned locust and cherry.

Wood shed:

8x14

Shop Stove:

Scandia 308, 8" flue through roof, sand bed in bottom of stove, has secondary damper

Small basement stove:

Boxwood, 6" flue, has fire bricks installed

Main home stove:

Old Mill 80, 6" flue, fire bricked

Will be running mostly Oak, tree was taken down late winter, immediately sectioned, and split. Have a feeling it's still going to be a little green come November... I am taking some of the drier pieces and splitting them thinner, and stacking inside my wood shed. Will have a backup load of seasoned locust and cherry.

Wood shed:

8x14