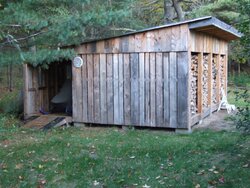

Finalizing the plans for my woodshed and was wondering what folks thought about using pressure treated wood.

The structure will be 8x12 built on 6 concrete sonotubes. The floor will be supported by crushed stone with 2 X 8 floor joists that rest on the stone. On top of the joists will be more 2x8 for a floor.

It will have 2x4s running horizontally spaced a few inches apart (air flow) on the sides and in the middle to split the shed in half. Obviously I will be using pressure treated for the posts out of the sonotubes, and floor joists.

My question is would you guys use pressure treated for the flooring, the 2x4s used for sides or the roof rafters?

I'm worried about insects liking the wood shed as much as the wood. Also worried about it being an open shed. I doubt much water will get in because I want to have a 2ft overhang on all sides but still a small concern.

Those who have a wood shed what did you do?

The structure will be 8x12 built on 6 concrete sonotubes. The floor will be supported by crushed stone with 2 X 8 floor joists that rest on the stone. On top of the joists will be more 2x8 for a floor.

It will have 2x4s running horizontally spaced a few inches apart (air flow) on the sides and in the middle to split the shed in half. Obviously I will be using pressure treated for the posts out of the sonotubes, and floor joists.

My question is would you guys use pressure treated for the flooring, the 2x4s used for sides or the roof rafters?

I'm worried about insects liking the wood shed as much as the wood. Also worried about it being an open shed. I doubt much water will get in because I want to have a 2ft overhang on all sides but still a small concern.

Those who have a wood shed what did you do?