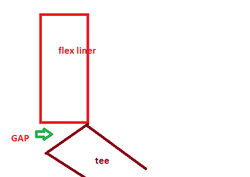

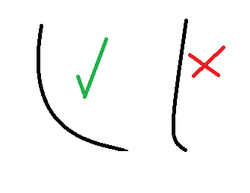

Found a nice looking SS tee at Rockford, 4" tee with 3" snout to connect, locking collar and clean-out bottom cap for $99. If, for clearance reasons, I need to rotate the tee maybe 20 to 30 degrees instead of being dead perpendicular to the stove, would this be OK?