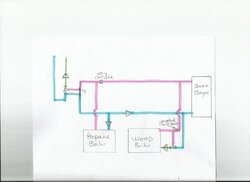

I've been putting it off long enough, and started my storage tank build. In general, I'm putting two 500 gal. Propane tanks vertically. That part is coming along nicely.

The advice I'm looking for is a simple temp measuring and digital display idea. I think four locations from top to bottom would be nice. I'm thinking the thread talking about WiFi capability is to high tech, nice features, but not necessary for me. Any suggestions?

Maybe I should bring this question to that other thread?

The advice I'm looking for is a simple temp measuring and digital display idea. I think four locations from top to bottom would be nice. I'm thinking the thread talking about WiFi capability is to high tech, nice features, but not necessary for me. Any suggestions?

Maybe I should bring this question to that other thread?

Last edited: