OK, so I am a big forum browser, but this is my first post ever. Someone please let me know if this is in the wrong section.

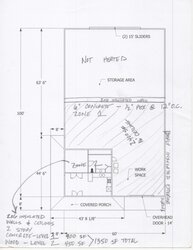

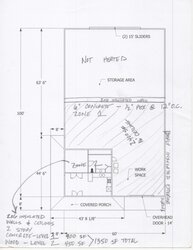

So here is my deal... I built a barn 3 years ago that is also my apartment. I had always wanted to have hydronic heat, and thought that since I have an almost endless supply of hardwood scraps at my disposal, a wood boiler would be best. I have the Orlan Eko 40 sitting in place. I ran 1/2" oxygen barrier pex on 12" centers in my slab and put 2" closed cell foam underneath and on the edges. I ran these in 280' loops and back to 2 manifolds for the 2 zones.

So there are two zones (Apartment & Shop):

Apartment is 2 stories, concrete downstairs, and wood floors upstairs (i made metal 'fins' and ran them over the pex on that loop). Whole thing is 2x6 walls R40 and R50 ceiling.

Shop is just one story with 16" ceilings, and not the greatest insulation. However I am not trying to get it up to room temp really, just want it a little more comfortable.

That being said, I have done almost all the work myself, but tried to hire a guy who was going to get my system turned on, and he ended up making all kinds of ridiculous errors, and basically just robbed me of $1,500. His name is James Lasater for anyone in the Nashville area. At least I was left with a little copper and a Taco Pump...

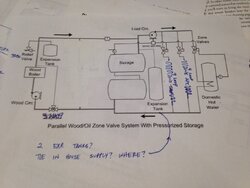

So I am about to cut all his piping out, and start over myself. I am thinking of about 500 gal storage, but not positive. I was planning a closed system, and this is the primary and only heat source. I have forced air run in the apartment for backup, and am not totally concerned about it working perfectly in there, but would LOVE some warmth in the shop.

I am posting some photos of the botched work from the guy I hired, and of my manifolds. I can also post photos of my schematics and other information. I just would greatly appreciate all of your knowledge because I know alot of people on here have real-world experience, and know that this can work!!

Thank you for all the knowledge y'all have already given me even though I have been silent until now!

Best regards, Jake

So here is my deal... I built a barn 3 years ago that is also my apartment. I had always wanted to have hydronic heat, and thought that since I have an almost endless supply of hardwood scraps at my disposal, a wood boiler would be best. I have the Orlan Eko 40 sitting in place. I ran 1/2" oxygen barrier pex on 12" centers in my slab and put 2" closed cell foam underneath and on the edges. I ran these in 280' loops and back to 2 manifolds for the 2 zones.

So there are two zones (Apartment & Shop):

Apartment is 2 stories, concrete downstairs, and wood floors upstairs (i made metal 'fins' and ran them over the pex on that loop). Whole thing is 2x6 walls R40 and R50 ceiling.

Shop is just one story with 16" ceilings, and not the greatest insulation. However I am not trying to get it up to room temp really, just want it a little more comfortable.

That being said, I have done almost all the work myself, but tried to hire a guy who was going to get my system turned on, and he ended up making all kinds of ridiculous errors, and basically just robbed me of $1,500. His name is James Lasater for anyone in the Nashville area. At least I was left with a little copper and a Taco Pump...

So I am about to cut all his piping out, and start over myself. I am thinking of about 500 gal storage, but not positive. I was planning a closed system, and this is the primary and only heat source. I have forced air run in the apartment for backup, and am not totally concerned about it working perfectly in there, but would LOVE some warmth in the shop.

I am posting some photos of the botched work from the guy I hired, and of my manifolds. I can also post photos of my schematics and other information. I just would greatly appreciate all of your knowledge because I know alot of people on here have real-world experience, and know that this can work!!

Thank you for all the knowledge y'all have already given me even though I have been silent until now!

Best regards, Jake

Attachments

Last edited: