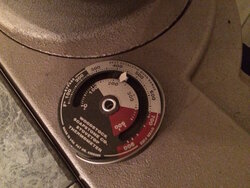

Help! We installed our new Progress Hybrid in August, and after that (in September or early October) we began to have our initial burns. We were careful to have small fires, engaged the cat at about 300 and thought we were doing really well. We had several burns of 550-600, which worried us--we thought that might have been too hot too soon. But the stove seemed fine with it.

At this point, though, we are having difficulty getting the stove temps above about 450, and with the cold weather we've been having, we need to run the stove hotter in order to heat the house. First, I tried to simulate our initial burns but using more wood, thinking that we would then get hotter burns. No such luck. We would have coals in the morning, though, which is good. Then I started up the fire with a large split in the back, a small split in the front, and a medium split in the middle on top of the other two. I let the temp on the stovetop next to the stove pipe get to a little over 500 before closing the damper down most of the way and engaging the cat. The temp, instead of rising, fell back to between 400 and 450.

Our burn times have been 6 to 8 hours during the day with three splits, and overnight about 10 hours with usually 4 to 5 splits, with the stove top at just under 300 in the morning.

When I called Woodstock, I was told to check the innocent screen visually through the glass because it could have gotten partially plugged. This surprised me. In fact I was told to remove it and burn the fire without it to see if it would get hotter, the theory being that then we'd know if it was the inconel. In looking at the screen through the glass, it doesn't "appear" to be plugged, and anyway, we'd need to get the stove fairly cool in order to reach in and remove it. With the temps the way they have been, we decided to limp along for a bit, hoping we could find something else that might be contributing to the issue. We're willing to do it, but wanted to ask here first.

The wood we're using has been seasoned for two years, and besides, the early burns seemed fine with it, so we don't think that it's that.

So can anyone give us a clue?

At this point, though, we are having difficulty getting the stove temps above about 450, and with the cold weather we've been having, we need to run the stove hotter in order to heat the house. First, I tried to simulate our initial burns but using more wood, thinking that we would then get hotter burns. No such luck. We would have coals in the morning, though, which is good. Then I started up the fire with a large split in the back, a small split in the front, and a medium split in the middle on top of the other two. I let the temp on the stovetop next to the stove pipe get to a little over 500 before closing the damper down most of the way and engaging the cat. The temp, instead of rising, fell back to between 400 and 450.

Our burn times have been 6 to 8 hours during the day with three splits, and overnight about 10 hours with usually 4 to 5 splits, with the stove top at just under 300 in the morning.

When I called Woodstock, I was told to check the innocent screen visually through the glass because it could have gotten partially plugged. This surprised me. In fact I was told to remove it and burn the fire without it to see if it would get hotter, the theory being that then we'd know if it was the inconel. In looking at the screen through the glass, it doesn't "appear" to be plugged, and anyway, we'd need to get the stove fairly cool in order to reach in and remove it. With the temps the way they have been, we decided to limp along for a bit, hoping we could find something else that might be contributing to the issue. We're willing to do it, but wanted to ask here first.

The wood we're using has been seasoned for two years, and besides, the early burns seemed fine with it, so we don't think that it's that.

So can anyone give us a clue?