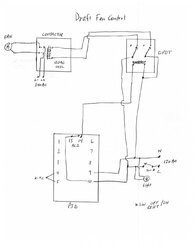

Maybe the discussion at this point, on use of a PID controller, deserves its own thread. Based on the comments I have corrected the drawing as to the 240VAC circuit.

Not sure if leaving one leg hot on the 220 VAC motor is permissible

My mistake in doing the drawing, the contactor switches both legs on the 240VAC circuit.

Why is second pole of DPDT relay being used to interrupt the neutral leg of the contactor coil circuit?

I'm not sure what the intent of this question is or its import. Is there a problem from doing this?

What happens if the entire system loses power for a second, a minute, or two hours?

A system loss of power for any length of time (including a loss of power only to the controller) would be the same as switching OFF-RESET / ON to "off" and then back to "on." On power-up of the controller the suppression feature on the alarm circuit opens the alarm low limit relay and restarts the draft fan, probably what is desired on a brief power outage, maybe not on a long outage, but then the operator would be aware of a major problem and probably has lots of problems to deal with, including restarting a fire in the boiler.

It looks like you have an auber(ins) controller. I can't tell if it is ssr or relay model.

It is an Auber controller, relay model.

Why not hook up your dpdt relay to pins 7 and 8 so the main output of your PID controls what it was designed to do. The green numbers will show your off temperature and your red numbers will show real time. The alarm can be adjusted to do the same thing, but is a low amperage internal relay on a made in china product, at least mine is a made in china product.. You have to push a button to see where the alarm is set, then it disappears. The main output is always displayed.

I thought about doing something like, because essentially all I'm using the PID for is to use the alarm circuit with suppression, which then operates like a limit switch with automatic reset on power-up (and on power failure/power restore). But it was the search for an automatic limit switch that led me to this PID controller. My thought on the low amperage internal relay is that it is only switching the coil on the DPDT relay, very low current draw. As to using pins 7 and 8, I don't think this provides for suppression of the low limit on power-up. Wouldn't the fan have to run on a cold start to get above the low limit? And it was automatic running the fan on cold start that was my primary goal. Do you see another way to do this?

... to get contactor control on 240v.

The PID will operate on 240VAC. The contactor I had has a 120VAC coil, and it as well as the DPDT relay, also 120VAC coil, were salvaged parts I had collected and I wanted to use them rather than purchase 240VAC parts. The circuit diagram could be simplified with use of 240VAC parts.

If you have a 450 degree off temperature and 100 degree hysteresis, that means on start up the PID wont turn on until 550. For my boiler and location of the sensor, that is about 45 seconds after the match is struck.

With the Wood Gun E500, there is little or no natural draft after the match is lit, so it is not possible to light a match and get the temperature up to a temperature to turn on the PID at 550F, for example. Do you see another way around this? My use of the alarm relay deals with this situation.

If you do a flue pipe sensor location that hysteresis as well as the on/off temperature I think would be set lower. Also I have the P set to off, the I set to off and the D set to off. So the temperature controller is in on/off function only.

While not relevant for use of the alarm relay, I also have these set to off and use the PID for on/off only. As to location of the sensor and the "off" limit setting, I think I will need to experiment a bit to make sure it goes off at a temperature about at the point where the boiler is not providing any heat to the system, probably a temperature of 10-20F above maximum boiler hot water output. The Wood Gun has a high limit of 185F, so probably a draft fan "off" limit of about 200F. On my Tarm the high limit is 190-195F and I have the draft fan shut down at 210F, and the Tarm sensor is located in the smoke box before the exhaust gases enter the flue.

. say my boiler fires and things are good..... say I built the fire small to avoid a boil over

. say my boiler fires and things are good..... say I built the fire small to avoid a boil over  ....having not added enough wood, my boiler ran out of wood to burn in the stove an/or there is such a little bit left it will never be able do anything....but my fan keeps on blowing cold "outside" air into the fire box, cause the AQs sayz so........... I would like the fans to stop blowing air when the water temp falls to 100-130 or so ...thereby not blowing-.what could be 30below air into the fire box /making me and the stove work to get back up to temp, when I get home to fix it. any ideas ?

....having not added enough wood, my boiler ran out of wood to burn in the stove an/or there is such a little bit left it will never be able do anything....but my fan keeps on blowing cold "outside" air into the fire box, cause the AQs sayz so........... I would like the fans to stop blowing air when the water temp falls to 100-130 or so ...thereby not blowing-.what could be 30below air into the fire box /making me and the stove work to get back up to temp, when I get home to fix it. any ideas ? . say my boiler fires and things are good..... say I built the fire small to avoid a boil over

. say my boiler fires and things are good..... say I built the fire small to avoid a boil over  ....having not added enough wood, my boiler ran out of wood to burn in the stove an/or there is such a little bit left it will never be able do anything....but my fan keeps on blowing cold "outside" air into the fire box, cause the AQs sayz so........... I would like the fans to stop blowing air when the water temp falls to 100-130 or so ...thereby not blowing-.what could be 30below air into the fire box /making me and the stove work to get back up to temp, when I get home to fix it. any ideas ?

....having not added enough wood, my boiler ran out of wood to burn in the stove an/or there is such a little bit left it will never be able do anything....but my fan keeps on blowing cold "outside" air into the fire box, cause the AQs sayz so........... I would like the fans to stop blowing air when the water temp falls to 100-130 or so ...thereby not blowing-.what could be 30below air into the fire box /making me and the stove work to get back up to temp, when I get home to fix it. any ideas ?