I have a Tarm OT-50 and because it is not a gassification boiler it produces a descent amount of creosote. I've heard from most people that if you have a non gassification boiler it is inevitable that you will have a chimney fire at some point. I've been doing some reading about chimney fires and i have some questions that i'm hoping I can get answered so I can better understand how to run my boiler and avoid a chimney fire as much as possible.

1. What actually causes a chimney fire? Is it heat from overfiring the boiler or is it sparks that make their way up the chimney and get stuck in the creosote?

2. Can I still have a chimney fire if I don't overfire my boiler and i try to run it in the optimal temp range as much as possible?

3. I realize that it is the creosote that burns. I have noticed that there are two different forms. One is this black tar like sticky stuff that is just plain nasty. The other kind is puffy and crusty and flakes off easily. I've noticed that if you apply heat to the the black tarry shiny stuff it puffs up and becomes brittle and flakes off. Are both of these present in my chimney? If the sticky stuff is present in the chimney how am i supposed to remove it because that stuff does not just come off with a brush? How are both created? Is the sticky stuff what is created if you don't run your boiler up to the optimal burn temp and then when it gets to temp the sticky stuff burns off and it puffs up and blocks the chimney? The crusty puffy stuff doesn't appear to burn. I've put a torch to it and all it does is glow. If this stuff builds up in my chimney do I still have to worry about a chimney fire, or is the main concern the reduced draft and the plugged chimney?

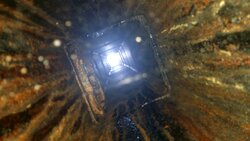

4. I have a hard time seeing what my chimney looks like from the bottom, even with a light and a mirror in the clean out. Can i get an idea of what my chimney looks like by looking through my boiler and into the connecting stove pipe, or will the stove pipe build up creosote faster than the chimney? How much faster does the single wall stove pipe build up creosote compared to the chimney?

5. If i have a chimney fire, i know i need to close everything up tight to cut off the draft to the chimney. Does this mean I also need to prop shut the barometric damper too? Is propping it shut good enough, or should i cover the entire opening with something to make sure the draft is completely blocked?

6. From researching on the internet i found something called Chimfex. It claims it starves out the chimney fire in as little as 22 seconds. I found them at a local hardware store and bought one for $25. Does anyone have any other advise or suggestions for extinguishing a chimney fire? I know i've heard things like throwing chain down the chimney or spraying water down it, but both of those either destroy the house or the chimney. I'm looking for simple things that work but won't harm the chimney or house if thats possible.

7. I've noticed what seems to be quite a bit of build up of creosote in the boiler. I've only ever run a wood stove. The amount of creosote seems alarming to me, but i don't really know what i'm looking at. How much creosote is ok inside the boiler and how much is too much? Can this creosote catch fire just like it does in the chimney or do i not need to worry about that? Do i need to scrub the inside of the boiler just like i do the chimney? A lot of the stuff in the boiler is black and shiny and sticky, if it is needed, how do i remove that stuff?

Any other information people can give me would be much appreciated.

1. What actually causes a chimney fire? Is it heat from overfiring the boiler or is it sparks that make their way up the chimney and get stuck in the creosote?

2. Can I still have a chimney fire if I don't overfire my boiler and i try to run it in the optimal temp range as much as possible?

3. I realize that it is the creosote that burns. I have noticed that there are two different forms. One is this black tar like sticky stuff that is just plain nasty. The other kind is puffy and crusty and flakes off easily. I've noticed that if you apply heat to the the black tarry shiny stuff it puffs up and becomes brittle and flakes off. Are both of these present in my chimney? If the sticky stuff is present in the chimney how am i supposed to remove it because that stuff does not just come off with a brush? How are both created? Is the sticky stuff what is created if you don't run your boiler up to the optimal burn temp and then when it gets to temp the sticky stuff burns off and it puffs up and blocks the chimney? The crusty puffy stuff doesn't appear to burn. I've put a torch to it and all it does is glow. If this stuff builds up in my chimney do I still have to worry about a chimney fire, or is the main concern the reduced draft and the plugged chimney?

4. I have a hard time seeing what my chimney looks like from the bottom, even with a light and a mirror in the clean out. Can i get an idea of what my chimney looks like by looking through my boiler and into the connecting stove pipe, or will the stove pipe build up creosote faster than the chimney? How much faster does the single wall stove pipe build up creosote compared to the chimney?

5. If i have a chimney fire, i know i need to close everything up tight to cut off the draft to the chimney. Does this mean I also need to prop shut the barometric damper too? Is propping it shut good enough, or should i cover the entire opening with something to make sure the draft is completely blocked?

6. From researching on the internet i found something called Chimfex. It claims it starves out the chimney fire in as little as 22 seconds. I found them at a local hardware store and bought one for $25. Does anyone have any other advise or suggestions for extinguishing a chimney fire? I know i've heard things like throwing chain down the chimney or spraying water down it, but both of those either destroy the house or the chimney. I'm looking for simple things that work but won't harm the chimney or house if thats possible.

7. I've noticed what seems to be quite a bit of build up of creosote in the boiler. I've only ever run a wood stove. The amount of creosote seems alarming to me, but i don't really know what i'm looking at. How much creosote is ok inside the boiler and how much is too much? Can this creosote catch fire just like it does in the chimney or do i not need to worry about that? Do i need to scrub the inside of the boiler just like i do the chimney? A lot of the stuff in the boiler is black and shiny and sticky, if it is needed, how do i remove that stuff?

Any other information people can give me would be much appreciated.

Last edited: