Unfortunately these are not the usable firebox dimensions. In reality you are not going to load much more than 3" above the bricks and not right up against the glass.I just looked up the firebox dimensions:

25.25" Wide by 15" Deep by 14" high.

Need a bigger insert

- Thread starter hamsey

- Start date

-

Active since 1995, Hearth.com is THE place on the internet for free information and advice about wood stoves, pellet stoves and other energy saving equipment.

We strive to provide opinions, articles, discussions and history related to Hearth Products and in a more general sense, energy issues.

We promote the EFFICIENT, RESPONSIBLE, CLEAN and SAFE use of all fuels, whether renewable or fossil.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

- Status

- Not open for further replies.

[quote="begreen, How are you breaking up the heat that is stratifying near the peak of the cathedral ceiling? Is this effective?[/quote]

We have a ceiling fan. Still in debate about which way to operate it. My procedure: I turn it on to blow up when I turn on the C550 fan. This warms the area that the stove is in and the front foyer that is on the opposite side of the balcony. This area is open. When I do a reload I change direction of the fan so that it blows down and spreads (tries) the heat to the other areas. My wife just leaves it in the up direction because that is what you are suppose to do in the winter. Not sure if it makes a difference with our setup.

Right now it is a toss up between the Hearthstone and Enviro. About the same size firebox. I do not think the summit will fit. My fireplace dimensions are 37" Front, 22" Deep at the bottom and 21" deep at the top, 22 1/2" at the back and 27" Tall.

Tried to get an answer about the Boston only blowing out the right side but Sherwood Ind. would not give me an answer.

Homestead is out.

Worried that it will take too long for the clyde to heat up. And it might be a problem keeping the temp at 600* with our current wood due to the small size.

We have a ceiling fan. Still in debate about which way to operate it. My procedure: I turn it on to blow up when I turn on the C550 fan. This warms the area that the stove is in and the front foyer that is on the opposite side of the balcony. This area is open. When I do a reload I change direction of the fan so that it blows down and spreads (tries) the heat to the other areas. My wife just leaves it in the up direction because that is what you are suppose to do in the winter. Not sure if it makes a difference with our setup.

Right now it is a toss up between the Hearthstone and Enviro. About the same size firebox. I do not think the summit will fit. My fireplace dimensions are 37" Front, 22" Deep at the bottom and 21" deep at the top, 22 1/2" at the back and 27" Tall.

Tried to get an answer about the Boston only blowing out the right side but Sherwood Ind. would not give me an answer.

Homestead is out.

Worried that it will take too long for the clyde to heat up. And it might be a problem keeping the temp at 600* with our current wood due to the small size.

Hogwildz

Minister of Fire

Your loading east to west to start with, that won't get you a really full load, or the most heat for sure.

Grisu

Minister of Fire

Not sure if another medium-size stove will really help you all that much. Let's say you load 2 cu ft of wood in the Rockland and now get one like the Enviro 1700 that can be filled to capacity at 2.5 cu ft. That's just 20% more under very careful assumptions. When the Rockland already struggles below 30 F outside, any other, barely larger insert will not fare much better.

Maybe that's your problem. Subpar wood will not put out much heat. How long can you sustain a burn? What's the insert temp after 6 hours for example? Could you get the weight of a normal load e. g by putting it in a bag and stepping on a scale?

Something I noticed about the wood I bought is it does not have much weight to it. Dry punky (i think is what it is called) looks rotted.

Maybe that's your problem. Subpar wood will not put out much heat. How long can you sustain a burn? What's the insert temp after 6 hours for example? Could you get the weight of a normal load e. g by putting it in a bag and stepping on a scale?

Bigg_Redd

Minister of Fire

T5 is the same size but projects into the room. Read that it is not going to help much.

You read bad information. PE inserts throw a lot of heat without a blower

Huntindog1

Minister of Fire

Sounds like that C550 by jotul was designed by marketing and not by engineering.

But I will give them this that inserts dont give them alot of options.

I like a firebox with usable dimensions.

Looking at your pics of your fire burning looks like your not using 25% of that firebox.

Looks like your getting secondary burn.

But I will give them this that inserts dont give them alot of options.

I like a firebox with usable dimensions.

Looking at your pics of your fire burning looks like your not using 25% of that firebox.

Looks like your getting secondary burn.

Had a light bulb moment when I was applying stove polish on last PM. Last time I cleaned the glass 1 1/2 weeks ago I put too much glass cleaner (not straight glass cleaner something specifically for stove glass that the store gave me) and it was running down onto the gasket. Wiped the glass clean put in the wood and off she went. That explains the discoloration. Glad about this because I did not overfire the stove. Anyway cleaned the area with steel wool and applied stove polish and rubbed off and looks much better now.

Tested a couple of splits to see where the MC is. One of the lightweight splits was 11.5% and a normal piece of oak was 16%.

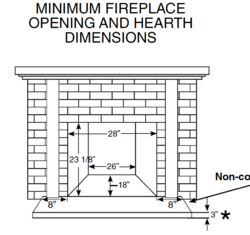

BE, Only 24" wide at 18" deep according to me doing a layout in CAD.

Hog, I have done n/s burns usually when doing a cold start. I thought e/w give the longer burn times so we change to that at reload. I read about raking coals forward put one split e/w in the back and then the rest n/s. Not sure what I am suppose to do with the coals that way. I have tried it but do not think I get the burn times not that we get stellar burn times to begin with.

Bigg, That is why I am considering the change. I have read different opinions about the heat. Not sure if the cast over plate gives the same radiant heat that a plate stove gives. That is why I am asking. Stores in my area do not have any of these in stock and would have to order it. I do not want to make the same mistake again.

Grisu, Another light bulb moment about the wood. Not the best for sure. I have normal weight pieces albeit on the smaller side that I am saving for when it gets colder. Should get longer burn times but we normally get the stove up temps between 500 and 700. I try and run it around 600 because that is where the stove gets a humming to it. I figure it is happy at that temp. Have not done a weight test. I am just learning about those things. Been reading up on it. I know the average is 8500 btu per pound per hour. My stove is rated for 65000 btu/hr and I figure a 3 hour burn time (not heat time) for a total of 195000 btu's. I divide the 195000 by 8500 and get 23 lbs of wood. Is that what I am suppose to load? Sounds like a lot with my current wood. Some of the stuff I just c/s/s one piece weights that and then some. No way the wife is loading those. Of course that is wet wood. Not sure what the weight will be dry. Saw some numbers not sure where and at the moment not too concerned about it.

Edit: Temp of the stove after 7 hours was 140. Was in the low 600's when I went to bed.

More about my house and location. Built 12 years ago. Pretty good insulation, all energy efficient double pane windows. I do live in a micro climate. We are 4 or 5 degrees colder than what they give for Hartford temps. Windy also which is good for seasoning fresh wood. Not so good for us.

Tested a couple of splits to see where the MC is. One of the lightweight splits was 11.5% and a normal piece of oak was 16%.

BE, Only 24" wide at 18" deep according to me doing a layout in CAD.

Hog, I have done n/s burns usually when doing a cold start. I thought e/w give the longer burn times so we change to that at reload. I read about raking coals forward put one split e/w in the back and then the rest n/s. Not sure what I am suppose to do with the coals that way. I have tried it but do not think I get the burn times not that we get stellar burn times to begin with.

Bigg, That is why I am considering the change. I have read different opinions about the heat. Not sure if the cast over plate gives the same radiant heat that a plate stove gives. That is why I am asking. Stores in my area do not have any of these in stock and would have to order it. I do not want to make the same mistake again.

Grisu, Another light bulb moment about the wood. Not the best for sure. I have normal weight pieces albeit on the smaller side that I am saving for when it gets colder. Should get longer burn times but we normally get the stove up temps between 500 and 700. I try and run it around 600 because that is where the stove gets a humming to it. I figure it is happy at that temp. Have not done a weight test. I am just learning about those things. Been reading up on it. I know the average is 8500 btu per pound per hour. My stove is rated for 65000 btu/hr and I figure a 3 hour burn time (not heat time) for a total of 195000 btu's. I divide the 195000 by 8500 and get 23 lbs of wood. Is that what I am suppose to load? Sounds like a lot with my current wood. Some of the stuff I just c/s/s one piece weights that and then some. No way the wife is loading those. Of course that is wet wood. Not sure what the weight will be dry. Saw some numbers not sure where and at the moment not too concerned about it.

Edit: Temp of the stove after 7 hours was 140. Was in the low 600's when I went to bed.

More about my house and location. Built 12 years ago. Pretty good insulation, all energy efficient double pane windows. I do live in a micro climate. We are 4 or 5 degrees colder than what they give for Hartford temps. Windy also which is good for seasoning fresh wood. Not so good for us.

Last edited:

Sounds like that C550 by jotul was designed by marketing and not by engineering.

Looking at your pics of your fire burning looks like your not using 25% of that firebox.

Looks like your getting secondary burn.

Hunt, I was typing when you replied. I am getting between 500 and 700 degree temps when loading 3 or 4 splits. I do not get long burn times. Have to admit that I am very nervous about loading it up with the wood (small splits) that i currently burning. Also I am not positive how I am suppose to be loading. If you see my post above with my numbers I believe I am suppose to be loading lots more wood. Going to wait for some replies from more experienced folk to see if that is how I am suppose to do it and give it a go. At least the scale will get used!

Huntindog1

Minister of Fire

Your not going to get an over fire if you load on a small bed of coals and you shut the input air down as soon as you can.

Usually what happens is a overly big bed of coals with a load of wood will fire off too quick and if the person dont adjust by shutting things down sooner then it will get hotter on you but its usually just that it gets hotter than a person likes and usually not a overfire issue. Plus your safer as your stove is sitting in a fireplace with a liner in masonry flue. Your pretty safe. Plus I wouldnt think you have any creosote built up so that helps also. As these epa stoves you haveto work pretty hard to get enough creosote built up to be an issue.

I have had my previous stove up to 900 stove top temps. But with a insert you cant measure stove top temp. Not sure what temp your taking?

Usually what happens is a overly big bed of coals with a load of wood will fire off too quick and if the person dont adjust by shutting things down sooner then it will get hotter on you but its usually just that it gets hotter than a person likes and usually not a overfire issue. Plus your safer as your stove is sitting in a fireplace with a liner in masonry flue. Your pretty safe. Plus I wouldnt think you have any creosote built up so that helps also. As these epa stoves you haveto work pretty hard to get enough creosote built up to be an issue.

I have had my previous stove up to 900 stove top temps. But with a insert you cant measure stove top temp. Not sure what temp your taking?

Huntindog1

Minister of Fire

My avatar shows the insert. I measure with an IR gun pointed a couple of inches in at the bottom of the slot. Not technically the top but where I have read to take readings.

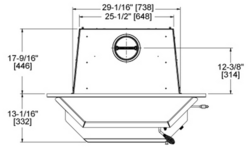

Thanks for the link will look at that unit also. Edit: To wide at the back with existing opening.

Thanks for the link will look at that unit also. Edit: To wide at the back with existing opening.

Huntindog1

Minister of Fire

Hunt, I was typing when you replied. I am getting between 500 and 700 degree temps when loading 3 or 4 splits. I do not get long burn times. Have to admit that I am very nervous about loading it up with the wood (small splits) that i currently burning. Also I am not positive how I am suppose to be loading. If you see my post above with my numbers I believe I am suppose to be loading lots more wood. Going to wait for some replies from more experienced folk to see if that is how I am suppose to do it and give it a go. At least the scale will get used!

When I had a 2.1 cu ft stove I loaded more than 3 or 4 splits and since your splits are small - medium you should be using more. I say you should get 3 splits on the back row east west load with the coals and ash raked forward. Loading that back row of 3 splits not on hot coals protects against over fire. The next row closest to the front would be the second row and most likely on coals and ash you should be able to load two splits. Then the last and front row the 3rd row load two more splits.

That would be 7 splits. Your heat output is directly related to the amount of wood you load and the quality of the burn and efficiency. Semi seasoned wood will greatly reduce your heat output. You should get 8 hour burns easily with that stove. If the wood is sub par you will be leaving the input air open a little too much and flushing more heat up the flue. Good wood gets you all kinds of things , more heat allows you to adjust input air lower and faster start ups so you dont waste wood just getting the heat built up in he stove to then get it shut back down for the over night burn, On restarts throw in a fire starter to speed things up sit it ontop of the wood load and lay some small split kindling a few pieces on top also and it will burn with the fire starteer and get the temps up in the box much quicker before you burn alot of your main load on start ups. As the heat from the fire starter and kindling adds to the heat of the coals. They work together for ideal startups and less wasted wood at start ups and lets the main wood be used for the all night burn.

I was getting 9 hour cycles easy with my stove and enough coals for easy restarts.

Last edited:

Huntindog1

Minister of Fire

Hamsey,

Too use one of the bigger inserts since your hooked to a stainless steel liner you could hire a masonry guy to do some decorative masonry work to fill in any gap behind the decorative surround of the insert. As the surround wouldnt be able to fit flush but it would only be an inch or two to worry about. Just an idea. The surround seal is not as critical since your hooked to the SS liner as in the old days the inserts would just be pushed into the fireplace and the surround would be sealed and the draft of the flue was supposed to draw everything up the chimney so no smoke leakage into the room. Todays liners are much safer setup.

Too use one of the bigger inserts since your hooked to a stainless steel liner you could hire a masonry guy to do some decorative masonry work to fill in any gap behind the decorative surround of the insert. As the surround wouldnt be able to fit flush but it would only be an inch or two to worry about. Just an idea. The surround seal is not as critical since your hooked to the SS liner as in the old days the inserts would just be pushed into the fireplace and the surround would be sealed and the draft of the flue was supposed to draw everything up the chimney so no smoke leakage into the room. Todays liners are much safer setup.

If the gap is under 2" it can be filled with a piece of angle metal painted black and attached to the back of the surround.

Grisu

Minister of Fire

Edit: Temp of the stove after 7 hours was 140. Was in the low 600's when I went to bed.

That's way too low after 7 hours. The insert is essentially out at that point. Your problem are short burn times either due to bad wood or small loads (or both). One pound of wood at 20% moisture will give you roughly 6000 BTU effective heat. If your three splits weigh together 10 lbs you load 60,000 BTU. Burn that over 6 hours you get only 10,000 BTU per hour. It is not surprising that this will not heat your home regardless of the insert. One cu ft of seasoned maple has 40 lbs. Load approx. 2 cu ft for 80 lbs total and you will get about 480,000 BTU. Over 8 hours that is roughly 60,000 BTU per hour. I am pretty sure that would make a difference. Once you have the new gasket in try larger loads. I do it the following way:

After a small startup fire to get the flue and insert warmed up (air about 50% closed, 2 to 3 small to medium splits + kindling), I rake the hot coals forward towards the door. I pack the fresh wood behind and on top of the coals until I almost reach the baffle, maybe leaving 1". With the door slightly ajar, I wait until the wood has caught fire. I open the door a bit again to let more air in and wait until I see good flames; then I close the door. I wait a few minutes until most of the wood is engulfed in flames then I start closing the air until the flames become slow-moving ("lazy"), air maybe 3/4 open. I wait until the flames pick up speed again, then I close the air further until the flames have noticeably slowed down again and so on. At the end, my air is usually fully closed but your insert may be different. You will see a few flames from the wood and lots of flames coming from the baffle tubes in the top. Stovetop should reach about 700 F after a short while. If the fire goes down too much, open the air again a bit, wait until it has picked up vigor again, and then keep closing as before. Try this method first during a day when you can monitor the fire for a few hours.

Last edited:

OK tried some of the methods mentioned above. I can only get 2 rows of splits in if I keep the wood behind the andirons (manual says so). Above freezing I have no problems heating the house it is below that I am having issues. Rake the coals forward put a load in and usually the wood has caught fire before I close the door. Let it char and start dampening it. I have no problem getting to 550 - 650* and above (try not to). Just do not think I can load enough wood in. Last PM loaded around 9:30 and had enough coals to restart in the AM. Outside temp of the stove was 130 inside was warmer. I am using bigger splits currently so that is helping.

Went and looked at a Clydesdale and am thinking about that. I know it is not much bigger but it has a deeper firebox and protrudes out some to get some radiant heat. I do know that some of the splits I just c/s/s (8" x 4" x 20") will take up to much space in the Jotul. Figure I can only get 1 row and 2 high with a real small split in front to ignite them.

Still working on it. Thanks for the help!

Went and looked at a Clydesdale and am thinking about that. I know it is not much bigger but it has a deeper firebox and protrudes out some to get some radiant heat. I do know that some of the splits I just c/s/s (8" x 4" x 20") will take up to much space in the Jotul. Figure I can only get 1 row and 2 high with a real small split in front to ignite them.

Still working on it. Thanks for the help!

mellow

Resident Stove Connoisseur

I do understand where you are coming from, I had a Jotul 450 for about a month and went back to a bigger insert for the overnight burns, nice inserts but like you I couldn't stand the burn times.

Huntindog1

Minister of Fire

Those inserts are just really small fire boxes starting to look like a new stove is in the works.

Keep us posted.

Clydesdale Insert doesnt look much bigger as to justify the cost of another insert.

I had a 2.12 cu ft fire box and could load 3 rows easily.

Take a look at these pics in an old post of mine.

https://www.hearth.com/talk/threads/rake-coals-forward-and-stove-start-up-pictures.80659/

Keep us posted.

Clydesdale Insert doesnt look much bigger as to justify the cost of another insert.

I had a 2.12 cu ft fire box and could load 3 rows easily.

Take a look at these pics in an old post of mine.

https://www.hearth.com/talk/threads/rake-coals-forward-and-stove-start-up-pictures.80659/

Huntindog1

Minister of Fire

If the gap is under 2" it can be filled with a piece of angle metal painted black and attached to the back of the surround.

I think the Summit is the answer with begreens idea. I think it can be done as the stove exhaust connected to the stainless steel liner so no need for the surround to have an air tight seal. Look around for a good metal working shop to fab up a custom spacer and buy matching paint to your surround.

- Status

- Not open for further replies.

Similar threads

- Replies

- 16

- Views

- 1K

- Replies

- 35

- Views

- 2K

- Replies

- 3

- Views

- 1K

- Replies

- 10

- Views

- 3K