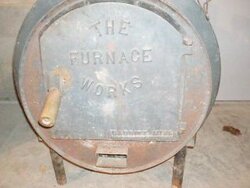

I received an old hot water jacket stove that has to be at least 50 years old. It has the name "The Furnace Works" on the door and the stove itself is shaped like a barrel. Under the door there is a rectangular hole that I believe either a blower or a draft control/damper was located. This stove will be piped into my hot water oil furnace and will become my primary heat source, with my oil furnace being the back up. My question is, can I find parts to replace the draft control? Should I plug this hole and put a draft control in the stove pipe? I want something that will be automatically controlled by a thermostat so that I can feed the fire and walk away. Thanks in advance for any help!

Old boiler wood stove...need draft control help

- Thread starter jimimiller

- Start date

-

Active since 1995, Hearth.com is THE place on the internet for free information and advice about wood stoves, pellet stoves and other energy saving equipment.

We strive to provide opinions, articles, discussions and history related to Hearth Products and in a more general sense, energy issues.

We promote the EFFICIENT, RESPONSIBLE, CLEAN and SAFE use of all fuels, whether renewable or fossil.