I recently purchased a Timber Ridge 55-SHP10, (I meant to say that in my post but said 25-PVDC instead and I can't seem to change it) and was quite disappointed with regards to heat output and ash build up. So I made the following non-permanent modifications to the stove which have improved it greatly. First off, I changed the control board from mode "D" to "C". Note the following pics show my changes.

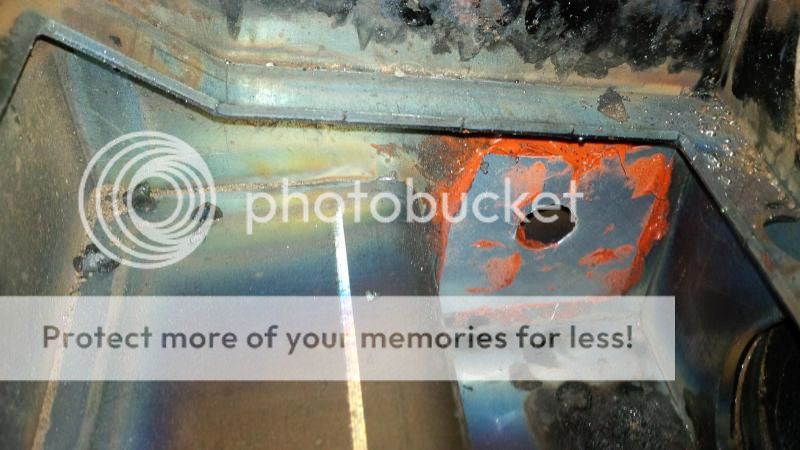

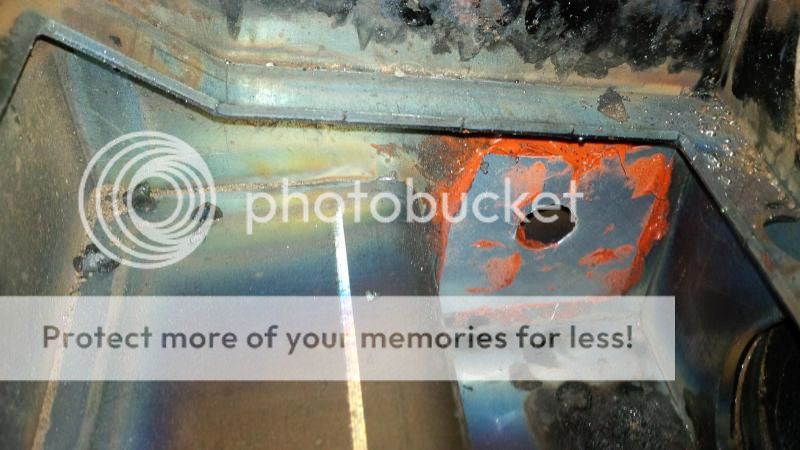

First off I down sized the two large holes under the burn plate to 1/2" by sticking two pieces of aluminium pop can over the holes with high temp. silicone. This cut down some of the air flow to the sides and left more to be used up through the burn plate.

Next, I made a new burn plate with 1/4" holes instead of 1/8" holes. I also reduced the size of the cut outs by the auger and eliminated the 8 holes on the bend of the plate, which were a waste of air in my opinion.

Here is all of the ash that is left in the burn pot after 16 hours of burning, as you can see most of it is in the ash bin where it should be.

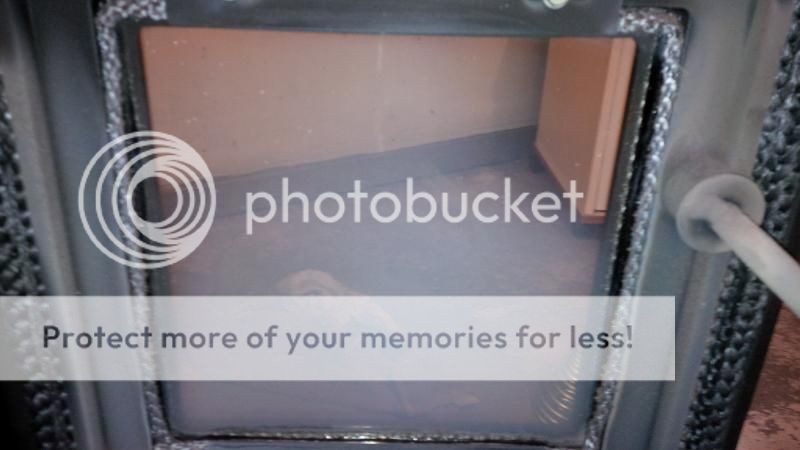

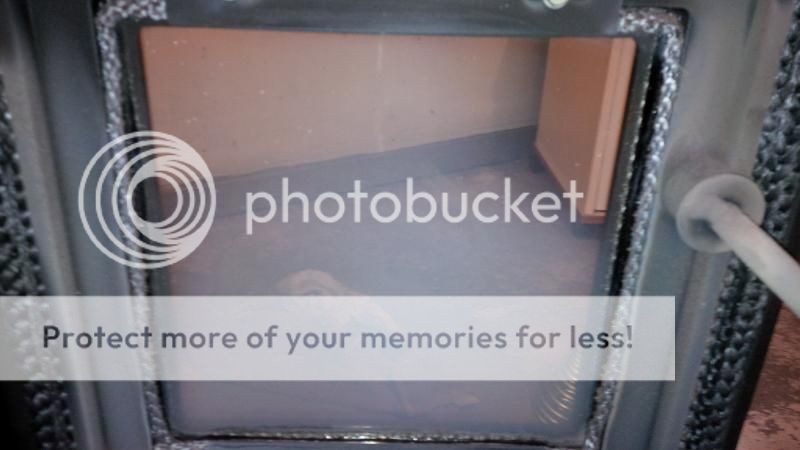

Here is my glass after 16 hours of burning.

And here is how she burns! Also, if this doesn't work for you, all you have to do is remove the aluminium and reinstall the original burn plate, and you're back to factory.

First off I down sized the two large holes under the burn plate to 1/2" by sticking two pieces of aluminium pop can over the holes with high temp. silicone. This cut down some of the air flow to the sides and left more to be used up through the burn plate.

Next, I made a new burn plate with 1/4" holes instead of 1/8" holes. I also reduced the size of the cut outs by the auger and eliminated the 8 holes on the bend of the plate, which were a waste of air in my opinion.

Here is all of the ash that is left in the burn pot after 16 hours of burning, as you can see most of it is in the ash bin where it should be.

Here is my glass after 16 hours of burning.

And here is how she burns! Also, if this doesn't work for you, all you have to do is remove the aluminium and reinstall the original burn plate, and you're back to factory.

Last edited: