I have owned a Tarm Solo 60 Plus for 14 years and have been running it with an STSS 1200 gallon storage solution. About a year ago the tank started overflowing because my heat exchangers have been leaking. I removed and replaced it with 3 - 250 gallon LP vertical tanks I purchased from Smokeless Heat. I'm in the process of piping the boiler now and would like to know from experience the best way to plumb the tanks. I've studied serial and parallel arrangements and think that maybe the easiest way to pipe it is parallel. I have very tight space constraints and can only place the tanks as shown in the attached vertical view drawing. Does anybody see any problems ganging the tanks this way? I plan to use ball valves on each tank connection as a balancing valve and adjusting where necessary. I've noticed in Europe they are quick to use a Bivalent shunt to select the lower half off the tank for withdrawal first, then switching or mixing to the upper tank port. Is this necessary? I would think the hot water would just rise in the tanks as it is pulled off via convection and the tank stratification would remain intact assuming I was careful with the return temps.

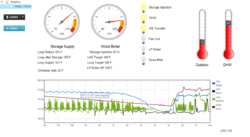

I have both radiant heat loads (via a variable speed injection pump) and 3 fan coils. The return water should be about 110 degrees at design temp from the radiant heat system but could be much hotter from the fan coils. I may run an injection pump from the storage tanks into a secondary loop which feeds the fancoils to lower their supply and return temps (25 delta T) . I'm using an EasyIO FG Beast 32 for a control platform (previously ran Tekmar) so controls are not an issue.

I have both radiant heat loads (via a variable speed injection pump) and 3 fan coils. The return water should be about 110 degrees at design temp from the radiant heat system but could be much hotter from the fan coils. I may run an injection pump from the storage tanks into a secondary loop which feeds the fancoils to lower their supply and return temps (25 delta T) . I'm using an EasyIO FG Beast 32 for a control platform (previously ran Tekmar) so controls are not an issue.