Hello all, I've been reading around the forums and planning for some time now, but it's about that time for my first post so here it goes.

New Wood Boiler - Attack DPX 45 Profi

Thermal Storage - Two 500 gallon 're-purposed' propane tanks stacked horizontally on top of each other.

New Chimney - Haven't ordered it yet but planing on doing DuraTech double-wall stainless. Installed inside house (just have to go up through one bedroom then out top (bedroom has cathedral ceilings)).

Existing Setup - Buderus Logano G115 Oil Boiler, Buderus Logalux ST150 Indirect Fired Domestic Hot Water Tank, 1 Circulator with 4 zones on zone valves, 1 zone for DHW and, 2 for each bedroom, and 1 for the living room.

Plans: I plan to install and configure controls the way Nofossil explains:

https://www.hearth.com/talk/wiki/pressurized-storage-solution-for-biomass-boilers/

What I have done so far (with video explination):

Got the new boiler in house: https://www.youtube.com/watch?v=DLBbsgTeluo

Video of existing setup: https://www.youtube.com/watch?v=X-Z9NZzMufc

Cleaned and placed bottom tank: https://www.youtube.com/watch?v=wLK8x8mm5dw

Cleaned and plan to place top tank tonight (wish me luck...) https://www.youtube.com/watch?v=zlSDzZypNUY

Cleaned, Painted and placed stand: https://www.youtube.com/watch?v=wrtbwT1wsfM

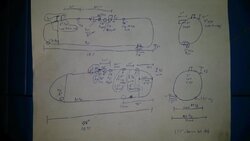

I found the three 500 gal tanks and stand on craigslist and paid $1200 (super lucky find I think). They are a little rusty but the guy I bought them from said they did work and he seemed like a decent guy. The tanks have ports all over the place as the video and drawing illustrates. He basically told me he simply out-grew the system for his heating needs and for how long he is away from home for extended periods of time.

I only have room to stack two tanks on top of each other. I know ideally I would like them vertical but don't have space for that either.

The above YouTube videos explain all of the tanks' and port locations and sizes. I have also attached some pictures and a very rough drawing of tanks with dimensions. I plan to 3D Model the tanks and stand with dimensions, but haven't gotten around to it yet. I also plan to modify Nofossil's plumbing schematic and electrical schematic to better fit my needs, basically just add another zone like I have and use Caleffi's ThermoBloc.

I'm no HVAC technician but do consider myself somewhat competent of a handyman. I can weld, solder, do basic carpentry, and went to school for engineering. I work as a teacher (IT) in a vocational high school and am friends with the HVAC instructor who has many years of experience. Once the final tank is in place and boiler is in place and I install the chimney, I may leave the rest of the work in the hands of that HVAC teacher or my brother from Colorado who is a hydronics engineer (if he is willing to make the trip).

One issue I hope to receive feedback about is that of the expansion tank. Along with the three 500 gallon tanks and stand, there is a custom made expansion tank he had made from what seems to be about a 150-200 gal propane tank. This would technically be considered a 'compression tank' since there is no bladder. Since there is no bladder both my brother and HVAC teacher don't think it is wise to use due to air and corrosion over the long term (I don't care about the periodic maintenance of checking level and draining/charging). This is a shame since an Extrol style expansion tank with bladder is not cheap for this size system.

I will take pics and a video of the expansion/compression tank and try to post later tonight.

Any thoughts, suggestions, criticisms, and concerns are greatly appreciated. I will keep this post as up to date as I can, thanks.

New Wood Boiler - Attack DPX 45 Profi

Thermal Storage - Two 500 gallon 're-purposed' propane tanks stacked horizontally on top of each other.

New Chimney - Haven't ordered it yet but planing on doing DuraTech double-wall stainless. Installed inside house (just have to go up through one bedroom then out top (bedroom has cathedral ceilings)).

Existing Setup - Buderus Logano G115 Oil Boiler, Buderus Logalux ST150 Indirect Fired Domestic Hot Water Tank, 1 Circulator with 4 zones on zone valves, 1 zone for DHW and, 2 for each bedroom, and 1 for the living room.

Plans: I plan to install and configure controls the way Nofossil explains:

https://www.hearth.com/talk/wiki/pressurized-storage-solution-for-biomass-boilers/

What I have done so far (with video explination):

Got the new boiler in house: https://www.youtube.com/watch?v=DLBbsgTeluo

Video of existing setup: https://www.youtube.com/watch?v=X-Z9NZzMufc

Cleaned and placed bottom tank: https://www.youtube.com/watch?v=wLK8x8mm5dw

Cleaned and plan to place top tank tonight (wish me luck...) https://www.youtube.com/watch?v=zlSDzZypNUY

Cleaned, Painted and placed stand: https://www.youtube.com/watch?v=wrtbwT1wsfM

I found the three 500 gal tanks and stand on craigslist and paid $1200 (super lucky find I think). They are a little rusty but the guy I bought them from said they did work and he seemed like a decent guy. The tanks have ports all over the place as the video and drawing illustrates. He basically told me he simply out-grew the system for his heating needs and for how long he is away from home for extended periods of time.

I only have room to stack two tanks on top of each other. I know ideally I would like them vertical but don't have space for that either.

The above YouTube videos explain all of the tanks' and port locations and sizes. I have also attached some pictures and a very rough drawing of tanks with dimensions. I plan to 3D Model the tanks and stand with dimensions, but haven't gotten around to it yet. I also plan to modify Nofossil's plumbing schematic and electrical schematic to better fit my needs, basically just add another zone like I have and use Caleffi's ThermoBloc.

I'm no HVAC technician but do consider myself somewhat competent of a handyman. I can weld, solder, do basic carpentry, and went to school for engineering. I work as a teacher (IT) in a vocational high school and am friends with the HVAC instructor who has many years of experience. Once the final tank is in place and boiler is in place and I install the chimney, I may leave the rest of the work in the hands of that HVAC teacher or my brother from Colorado who is a hydronics engineer (if he is willing to make the trip).

One issue I hope to receive feedback about is that of the expansion tank. Along with the three 500 gallon tanks and stand, there is a custom made expansion tank he had made from what seems to be about a 150-200 gal propane tank. This would technically be considered a 'compression tank' since there is no bladder. Since there is no bladder both my brother and HVAC teacher don't think it is wise to use due to air and corrosion over the long term (I don't care about the periodic maintenance of checking level and draining/charging). This is a shame since an Extrol style expansion tank with bladder is not cheap for this size system.

I will take pics and a video of the expansion/compression tank and try to post later tonight.

Any thoughts, suggestions, criticisms, and concerns are greatly appreciated. I will keep this post as up to date as I can, thanks.

Attachments

-

drawing.jpg97.5 KB · Views: 616

drawing.jpg97.5 KB · Views: 616 -

hoist.jpg170.6 KB · Views: 607

hoist.jpg170.6 KB · Views: 607 -

botomm tank top.jpg183.2 KB · Views: 626

botomm tank top.jpg183.2 KB · Views: 626 -

old temp port.jpg163.7 KB · Views: 597

old temp port.jpg163.7 KB · Views: 597 -

plug.jpg183.1 KB · Views: 596

plug.jpg183.1 KB · Views: 596 -

ports1.jpg284.8 KB · Views: 569

ports1.jpg284.8 KB · Views: 569 -

ports2.jpg272.2 KB · Views: 554

ports2.jpg272.2 KB · Views: 554 -

return bottom.jpg119.4 KB · Views: 586

return bottom.jpg119.4 KB · Views: 586 -

union.jpg155.9 KB · Views: 579

union.jpg155.9 KB · Views: 579