Guys,

First post but 7yr Aqua-Therm 145 owner......here's what I need help with..... Boiler is outside in shed, approx 90ft from house, down hill (slight). With outside temps up and down this winter, I've been having "boiler over" issues this past year, after just running with straight water, instead of 50% glycol. Have been setting aquastat between 160-170 to compensate for ambient temps.

Have a stacked plate exchanger at inside hydronic oil boiler, and use the existing baseboard loop as a constant dump zone with constant running taco 007.

Temp. relief valve has been going off and would like to create a expansion/dump zone at boiler site....or believe that's what I need to do? If heat isn't being used over period of time, it just gets to be too much, no matter what I set aquastat to.

What do you need from me to help figure this out? I've read a bunch of articles and have fine tuned this system over past 4yrs (inside and outside).....but would like to fix this.

My 145's capacity is 48 gal......and have about a 90ft run of 1" pex loop. Pressure relief (30 lb) and temp relief valves (210 blow off) are in place.....

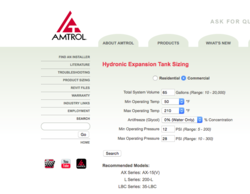

Can I just put a tank (how big if yes?) above highest pipe point, remove temp relief valve, and pipe up to that to let water expand up there and then let gravity feed back down? Or???

Thanks for your time to look at this! I appreciate any help possible.

First post but 7yr Aqua-Therm 145 owner......here's what I need help with..... Boiler is outside in shed, approx 90ft from house, down hill (slight). With outside temps up and down this winter, I've been having "boiler over" issues this past year, after just running with straight water, instead of 50% glycol. Have been setting aquastat between 160-170 to compensate for ambient temps.

Have a stacked plate exchanger at inside hydronic oil boiler, and use the existing baseboard loop as a constant dump zone with constant running taco 007.

Temp. relief valve has been going off and would like to create a expansion/dump zone at boiler site....or believe that's what I need to do? If heat isn't being used over period of time, it just gets to be too much, no matter what I set aquastat to.

What do you need from me to help figure this out? I've read a bunch of articles and have fine tuned this system over past 4yrs (inside and outside).....but would like to fix this.

My 145's capacity is 48 gal......and have about a 90ft run of 1" pex loop. Pressure relief (30 lb) and temp relief valves (210 blow off) are in place.....

Can I just put a tank (how big if yes?) above highest pipe point, remove temp relief valve, and pipe up to that to let water expand up there and then let gravity feed back down? Or???

Thanks for your time to look at this! I appreciate any help possible.

..and its brand new

..and its brand new  ...I need one made by NASA

...I need one made by NASA