Found this site in my attempts to figure out my new to me boiler. It is an Eko-Vimar circa 2005, gasification unit and is 40k btu I believe. This is outside and is used to heat the house that I just bought before winter. The system was crudely installed and in no way works properly. The hot water goes from the top of the boiler into the house and directly into the heat exchanger in the forced air furnace. Then it returns to the boiler via a pump. There are some plastic 55 gallon drums in the basement with pex tubing coiled inside them to be used as a heat storage battery but the water has to be manually diverted there with valves and an auxilary pump. When the temps here were around 40° outside, the system worked well with those barrels were hot to the touch and I had 65°c boiler temps. Now that it is sub zero outside, the system cant keep up and the only way I have any heat at all is if I close off the battery valves and run straight thru the furnace. Even then my boiler temps are rarely above 45°c. I know there are supposed to be thermal valves and other devices in place but I don't know what to do and I have very little money to make this system work better so any help is greatly appreciated!!

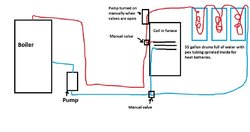

Here is a crudely drawn picture of my setup.

Please don't flame me, I didn't install this system!!

Here is a crudely drawn picture of my setup.

Please don't flame me, I didn't install this system!!