i would really appreciate some feedback on this.....

I need to buy around half of my logs and since getting my first stove in Dec 2013 I always used the same supplier, who was very reliable. However the last two times I ordered from him his logs haven't performed so well... Some of the splits seemed too thick IMO - often 6 inches at the widest part.. But more to the point, the MC in the centre of most of these larger logs, when freshly split, was as high as 28%, even when the reading on the outside was as low as 16%. These are sold as kiln dried logs.

When I emailed him about this today he gave me a detailed reply, justifying the MC readings thus:

What do you think of what he's saying? (I stacked these logs within hours of delivery in a covered shed with doors, so would be dismayed to hear that the MC might have increased significantly. Also..Is this 'true moisture content' measurement he descirbes an acceptable way to measure MC? My thought is to find another supplier, but I am aware I am still very much a newbie so he may be right and I may be doing him an injustice.

Thanks....

I need to buy around half of my logs and since getting my first stove in Dec 2013 I always used the same supplier, who was very reliable. However the last two times I ordered from him his logs haven't performed so well... Some of the splits seemed too thick IMO - often 6 inches at the widest part.. But more to the point, the MC in the centre of most of these larger logs, when freshly split, was as high as 28%, even when the reading on the outside was as low as 16%. These are sold as kiln dried logs.

When I emailed him about this today he gave me a detailed reply, justifying the MC readings thus:

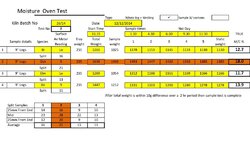

Regarding moisture content (MC), there are 3 ways in which to take moisture content, 1) Surface moisture with a Pin Meter in the centre of the log, 2) Split in half , we take 3 measurements one in the middle and one near each end, 3) Oven test we split a log into small kindling and weigh it and when we are sure the weight is static we calculate the true moisture content from there via spreadsheet. I attach a copy of the most recent Oven test and you will see where I have highlighted brown, that an Oak log recorded 28 in the centre when split, and ultimately recorded 18% when the Oven test was complete. The split MC recorded at 21% average of the 3 readings. Pin meters are not 100% reliable and MC varies over the whole log anyway so the acid test is always an Oven test which is 100% reliable.

Regarding Kilning, we take a kiln batch out after the surface moisture reads 12% 0r less, the Kiln is also computer controlled and we will know the MC of the air in the kiln at the end of the batch. If a kiln contains mixed Oak we would expect the oak to be 10-12% whilst all else would be below 10% normally. We then check MC regularly as the logs are being bagged and periodically do oven tests. Over time we know that when we have less that 10% surface moisture after a kiln cycle that the moisture by oven test will always be under 15- 20% for most species. However all logs will rise in surface MC after kilning, as they absorb moisture when humidity is high in the winter, and centre moisture content will migrate to a degree so your getting 20% on the outside and 28% in the centre would not surprise me dependant on handling and storage at your end.

On our website we guarantee less than 24% , so I don’t know where you got 20% although ours should always be well into the teens at least which gives us insurance so to spaek. Industry norm stipulates 25% or lower as being good for purpose.

What do you think of what he's saying? (I stacked these logs within hours of delivery in a covered shed with doors, so would be dismayed to hear that the MC might have increased significantly. Also..Is this 'true moisture content' measurement he descirbes an acceptable way to measure MC? My thought is to find another supplier, but I am aware I am still very much a newbie so he may be right and I may be doing him an injustice.

Thanks....