- Nov 30, 2010

- 126

Hey guys,

I recently got a Ridgewood Model# 6000 OWB. I installed it myself, and later had the company's installer come out to help diagnose the problem. He said I installed everything correctly and very cleanly. He left dumbfounded that we could not get the system to heat my house. I have a hard time believing this. Please note that our Side arm is working just fine, and in fact I have yet to run out of any hot water. The electricity is off to the hot water heater, and has been for a few days now.

Some background. The pump on the OWB is a Honeywell model# PC3F1558IUF00.

It is a 3 speed pump, and the Manual says that it has a maximum flow rate of 15GPM on high speed (which I have it set on)

I am running a 32" Sidearm, which is 3/4" inside 1 1/2".

The water to water heat exchanger was included with the OWB purchase and does not display a brand name. It

just says the following " 50-RD40 Capacity up to 300,000 Btu/h @ 30.7 GPM PD<5 psig

The houses Boiler system is a Slant/fin boiler with a Grundfos Type UP 15-42F pump. The thermostat for the water temp. was previously set a 200° (seemed really high to me)

There is approximately 140ft of 3/4" copper pipping of which 90ft is baseboard with fins. According to the front gauge on the house boiler the pressure in the lines is at about 20 to 25 psi.

The house has a total of 1,638 sq ft. to heat. We can not get the house above 60°F without the help of our pellet stove.

There is approximately 75ft of insulated 1" Pex tubing running from the back of the OWB to the house 6ft under ground. Once in the basement, it immediately 90°'s and runs 10ft through another wall where it takes another 90° turn towards the Sidearm. It then takes two more 90° turns into the Sidearm. From the side arm it travels less than 3ft through 2 90° turns into the water to water plate exchanger. Then it leaves the plate exchanger and goes through 4 90° turns back to the OWB.

The guy who came out from Ridgewood bumped up the High Set Point to 200° from the pre set 180° and said it should help. Well it has allowed us to only get the house up to 65° and that is running 100% everything on high.

When we had propane, we could get the house to any temp we wanted, although we only used it for only one winter because it went through so much propane. The system has sat empty for the last 6 years, until this install. I have already got all the air out of the system... have bleed it about 10 times now to make sure.

Someone school this dummy why this set up is not working??? I see right off the bat that the pump is only capable of pumping half of the GPM that the exchanger will take, but am not sure if this is the problem. Any help would be more than appreciated.

Below are some photos to help describe my setup.

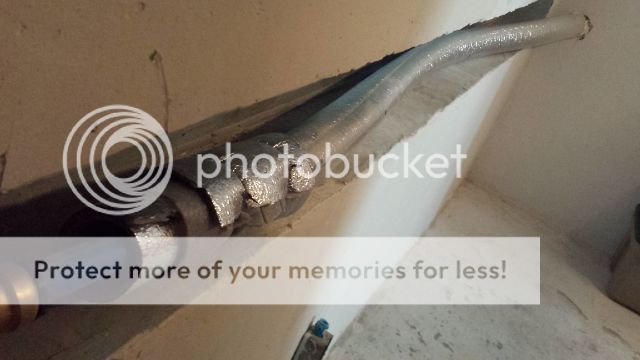

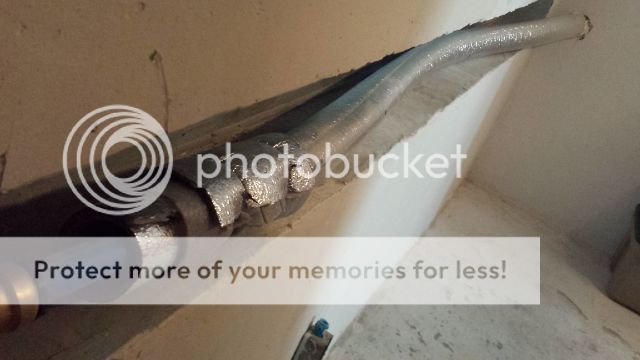

Where the pex enters the house

Then into the furnace room

And inside the furnace room

I recently got a Ridgewood Model# 6000 OWB. I installed it myself, and later had the company's installer come out to help diagnose the problem. He said I installed everything correctly and very cleanly. He left dumbfounded that we could not get the system to heat my house. I have a hard time believing this. Please note that our Side arm is working just fine, and in fact I have yet to run out of any hot water. The electricity is off to the hot water heater, and has been for a few days now.

Some background. The pump on the OWB is a Honeywell model# PC3F1558IUF00.

It is a 3 speed pump, and the Manual says that it has a maximum flow rate of 15GPM on high speed (which I have it set on)

I am running a 32" Sidearm, which is 3/4" inside 1 1/2".

The water to water heat exchanger was included with the OWB purchase and does not display a brand name. It

just says the following " 50-RD40 Capacity up to 300,000 Btu/h @ 30.7 GPM PD<5 psig

The houses Boiler system is a Slant/fin boiler with a Grundfos Type UP 15-42F pump. The thermostat for the water temp. was previously set a 200° (seemed really high to me)

There is approximately 140ft of 3/4" copper pipping of which 90ft is baseboard with fins. According to the front gauge on the house boiler the pressure in the lines is at about 20 to 25 psi.

The house has a total of 1,638 sq ft. to heat. We can not get the house above 60°F without the help of our pellet stove.

There is approximately 75ft of insulated 1" Pex tubing running from the back of the OWB to the house 6ft under ground. Once in the basement, it immediately 90°'s and runs 10ft through another wall where it takes another 90° turn towards the Sidearm. It then takes two more 90° turns into the Sidearm. From the side arm it travels less than 3ft through 2 90° turns into the water to water plate exchanger. Then it leaves the plate exchanger and goes through 4 90° turns back to the OWB.

The guy who came out from Ridgewood bumped up the High Set Point to 200° from the pre set 180° and said it should help. Well it has allowed us to only get the house up to 65° and that is running 100% everything on high.

When we had propane, we could get the house to any temp we wanted, although we only used it for only one winter because it went through so much propane. The system has sat empty for the last 6 years, until this install. I have already got all the air out of the system... have bleed it about 10 times now to make sure.

Someone school this dummy why this set up is not working??? I see right off the bat that the pump is only capable of pumping half of the GPM that the exchanger will take, but am not sure if this is the problem. Any help would be more than appreciated.

Below are some photos to help describe my setup.

Where the pex enters the house

Then into the furnace room

And inside the furnace room