I am running my Tarm HS 4.0 for the first year this year. It heats extremely well. Running roughly 3k square feet. 5 zone system with 1 radiant floor heat zone. The rest are old cast iron radiators. It is a new install. Mostly copper from the boiler to the header system, and pex from there to the radiators. The radiant floor heat is running with a mixing valve.

I am plowing through about 1 ton of fuel a week...be it corn or pellets. To me that is an insanely high consumption rate....

I have propane forced air backup. It heats just fine. I'd run that 100% but really wanted this biomass to work.

Few observations, FWIW:

1.) metering valves are on the output side of the registers

2.) Radiant floor heat does not work well. That room will not get above 55 degrees. Its pex only with no other heat transfer mechanism in line.

3.) Burning corn might be the issue right now because of moisture content - it makes big clinkers and hurts the efficiency a bit because of it.

4.) Its running a flue dampener - Tarm called for it

Any suggestions? I can't afford $800 to $1000 per month in fuel. I'd be better off pulling it and putting a propane boiler in. I also have a Harman Accentra insert for the addition room (one with radiant floor heat) - it's just not installed yet.

Is there anything obvious I need to check? Any help or suggestions would be appreciated.

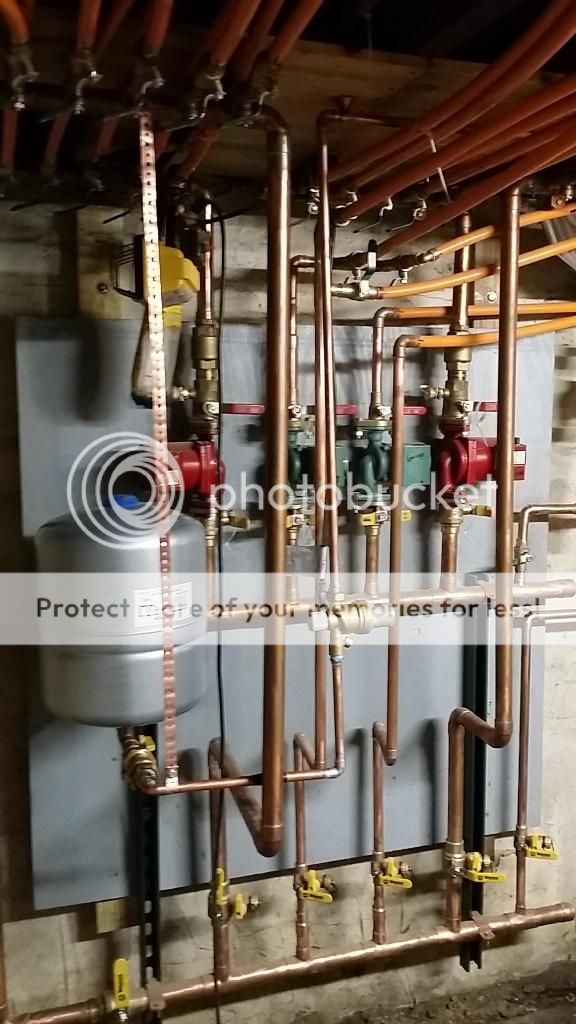

Video attached of the boiler. I'll dig up pics of the manifold as well

I am plowing through about 1 ton of fuel a week...be it corn or pellets. To me that is an insanely high consumption rate....

I have propane forced air backup. It heats just fine. I'd run that 100% but really wanted this biomass to work.

Few observations, FWIW:

1.) metering valves are on the output side of the registers

2.) Radiant floor heat does not work well. That room will not get above 55 degrees. Its pex only with no other heat transfer mechanism in line.

3.) Burning corn might be the issue right now because of moisture content - it makes big clinkers and hurts the efficiency a bit because of it.

4.) Its running a flue dampener - Tarm called for it

Any suggestions? I can't afford $800 to $1000 per month in fuel. I'd be better off pulling it and putting a propane boiler in. I also have a Harman Accentra insert for the addition room (one with radiant floor heat) - it's just not installed yet.

Is there anything obvious I need to check? Any help or suggestions would be appreciated.

Video attached of the boiler. I'll dig up pics of the manifold as well

Last edited: