When was the last time the stove burned correctly and when is the last time you cleaned the stove and vent pipe. Does the damper knob have an affect on the flame? Sounds like it's an air problem. I have a Quest plus and if I recall, my damper has a rod and yours has a knob but both do the same thing and the stoves are very similar. You can see the damper control knob on the right of my stove.

If you have already done these let me know but go through some basic checks.

First, Check for air leaks around your door, and glass.

Verify that both of the ash slide covers are shut on the left and right floor of the firebox.

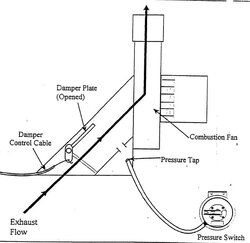

Make sure your vent pipe is clean from the exhaust motor out. Depending on your exhaust configuration, you will want make sure the exhaust blower motor housing and impeller is clean as well. Check to verify that your exhaust motor is functioning and coming up to speed. (I like to bench test motor as it sits in the housing to verify it comes up to speed and the impeller isn't bent and vibrating)

If all is good there, you may have a blockage between your exhaust motor and the fire box. you will need to pull the blower motor and either blow the stove out with compressed air or use a shop vac with a small hose to get around the corners and difficult to reach areas. Take your stove outside or in the garage when you do this. The exhaust vents in the fire box on this stove are in the upper right and left corners beside the heat tubes. You will have to remove the deflector plate to get to them and getting the ash can be challenging. (I like to put the shop vac hose into the exhaust housing and with the shop vac on, hit the two exhaust vents with compressed air. does a nice job)

Not positive the configuration of the damper but make sure it is functioning when the knob is turned. If it is not, this may be your problem and more than likely it is stuck in a near closed position.

Check the square combustion air tube below the burn pot to make sure its not blocked and the burn pot is seating correctly when it is in place.

After that, you may be looking at a control panel issue however I think you're going to find it is an air problem.

Just a good cleaning can effect your stoves performance greatly and you really have to keep up with them especially when they are in service. I really like my Quest Plus. I modified the burn pot slightly and it runs flawlessly and It's a very quiet stove.

Let me know how you make out.

Bob

Actually forum member Bob. P gives some very good info on how to clean the hard to get to area in his post further up in this thread. Please study his post an extra time... Remember: 80% of all problems with a pellet stove is caused by a clogged up exhaust!!

Actually forum member Bob. P gives some very good info on how to clean the hard to get to area in his post further up in this thread. Please study his post an extra time... Remember: 80% of all problems with a pellet stove is caused by a clogged up exhaust!!