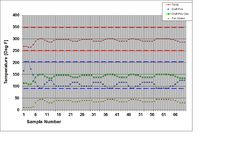

She is up and running, test burn yesterday went well with only minimal changes to the default program.

I made a few more tweeks today, lots of parameters to adjust Impressed so far.

Impressed so far.

My original plan was to tap into the outside air tube and control with an automotive type throttle body.

Decided to ditch that idea due to the O.A. system not being air tight enough to control with. Too many small leaks to deal with, and opportunities for future air leaks. These things don't flow much air, as we all know a small leak isn't good.

So i went with an easy backup plan, just for the heck of it. Didn't expect much from this set up but was pleasantly surprised.

I made a few more tweeks today, lots of parameters to adjust

Impressed so far.

Impressed so far.My original plan was to tap into the outside air tube and control with an automotive type throttle body.

Decided to ditch that idea due to the O.A. system not being air tight enough to control with. Too many small leaks to deal with, and opportunities for future air leaks. These things don't flow much air, as we all know a small leak isn't good.

So i went with an easy backup plan, just for the heck of it. Didn't expect much from this set up but was pleasantly surprised.

Last edited: