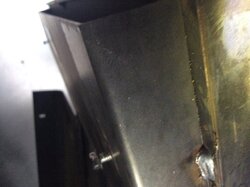

I was looking at my Lopi Liberty last night thinking how much I resembles a Fisher and decided to take the side heat shields off to clean underneath. Noticed the spot welds along the rear seams which surprised me because I would have imagined them to be welded all along, then noticed the welds themselves were very shallow and were split.

The top plate is welded to the sides very nicely and presentable. Is this how they are put together with spot welds and should I have the welds repaired? I traded for this stove a couple years back and it was new then. My walls have heat shields and I am going to paint the sides of the stove so to leave the Lopi shields off.

Really not how I thought this stove was put together, it may be 100% sound solid manufacturing practice intended to be hidden behind the heat shields but seems a little skimpy and a easy way for air to get in. Unless there's welds inside or something this might be why my burns have been shorter than What I remember. New gaskets,sealed stove pipe,no cracks on baffle assembly that I have seen posted elsewhere.

Last edited by a moderator:

!

!