Well, some success this morning. I started with a flat bed of ash, knowing there were some coals in it. Cat probe was well down below inactive. From the the moment my first piece of tinder burst into flame to engaging the cat I got my elapsed time down to 19 minutes.

One variable I hadn't been controlling for earlier, turn the convection fan off. I don't know if I have been doing that consistently in the past, but I was careful to do it today. Running the convection fan - blowing room air over the stove top- is great for moving heat around the house, but logically an impediment to heating up the stove from a cold start.

Second, for now I am sticking with leaving the thermostat at 3/3 on my Ashford. Properly adjusted i can turn it up to 3.5 or maybe 4/3 when I meet the hard stop in the mechanism with the knob pointing right at 6 o'clock. I might in the future have to turn that knob to wide open to cut my time a bit further, but it will be one more thing to remember, "turn the Tsat back down to 3/3 when engaging the cat."

Also, getting the cat engaged does not instantly result in a clean stack plume, as Highbeam has observed repeatedly.

Finally, I am not equipped to start the stove this way and monitor my stack plume simultaneously. I have the door pretty wide open for quite a while using the method I am about to describe, running out in the yard to check the stack while the loading door is wide open is going to take two people. So I don't know how long after the first piece of tinder burst into flames (T=0) I first was generating a visible plume out the stack (T sub

regulated =0).

I suspect I am blowing visible smoke longer after I have the cat engaged than I am saving time on the front end by starting to heat the stove without having a visible plume. Make sense?

Anyway, I have just been kinda stewing on the ideas y'all already provided in this thread, tried this and I know what I am going to try next.

NB: I have been loading EW for a couple weeks now. I am pretty sure I am getting more complete burns and less ash, but when it warms up here a little bit i will go back to NS loading so I am not worrying about burning splits rolling onto the glass.

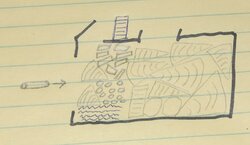

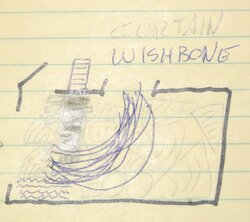

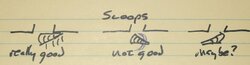

First, fill the back of the box with regular splits and a couple bio-logs if you are using them. In the drawing attached, pencil lines are all wood. Sharpie is the side profile of my stove box. The blue square with the perpendicular lines is my cat. The wavy blue lines represent the coals I was able to scrape together this AM, just inside the door.

So fill the back of the box with regular splits, and I did my darndest to block the bypass flue exit with splits. I got to within about a centimeter (maybe half an inch) of blocking the front half of the firebox from the bypass exit with the last split up in there.

Then one regular split just inside the door resting partly on the firebrick and partly on the coals. Then some tinder (wood shavings) on the back half of the coal bed .

The side to side kindling pieces about half an inch in diameter, about a cm in diameter, pretty small stuff that will light pretty easy but not burn out in 15 seconds. These are all 16" pieces.

What I did was keep the loading door wide open until I mention it again. I got the back half of the box full. I got one decent split at the front resting partly on the coal bed. Some tinder, and maybe three or four 16" pieces half inch in diameter laying on the tinder. The tinder bursts into flames. The three or four 1/2" diameter pieces start burning.

Now some little tiny more tinder pieces (maybe 1/4" in diameter by 3" long), perpendicular to the 1/2" x 16" kindling that just lit. Then more 1/2x16 kindling, more perpendicular tinder, more kindling, to even with the top of the split at the front.

Keep the loading door wide open. Looking for the kindling to be lit all the way across left to right, not just burning at the ends.

Once the 1/2x16 kindling is going good, side to side, lit up all the way across, then a second split to fill more of the doorway opening, and fill the area behind the second door split, the area of the burning half inch diameter stuff with small splits, about the nominal size of 1x2 and 1x3 inch stock from Lowes or Home Depot or a lumber yard. Not really 1x3", nominal 1x3 lumber sized.

Loading door still wide open. What happened for me was my flue started to rumble like it was drawing about here, but without the flue probe budging off room temp. Let it run a while, I wanted the 1x2 and 1x3 stuff fully engulfed if I could.

Once the 1x2 and 1x3 is fully engulfed, then move the loading door to where it is just barely cracked open and get the blast thing going on.

Once the flue is hot by ear or by probe close the loading door, once the cat is hot engage the cat.

Next time I am going to break some half inch kindling pieces in half and lay them perpendicular to the already burning 1/2 stuff, between the two regular sized splits at the front. I hope that will let some air through to light off the 1x2 and 1x3 even better.