Hey all, I'm a fairly new member here and long time lurker. I thought I'd start my first thread with a little wood shed build to get things off in the right direction. I'm in the concept phase right now and I've pieced together ideas that I've liked from a bunch of other sheds that I've seen here and elsewhere online.

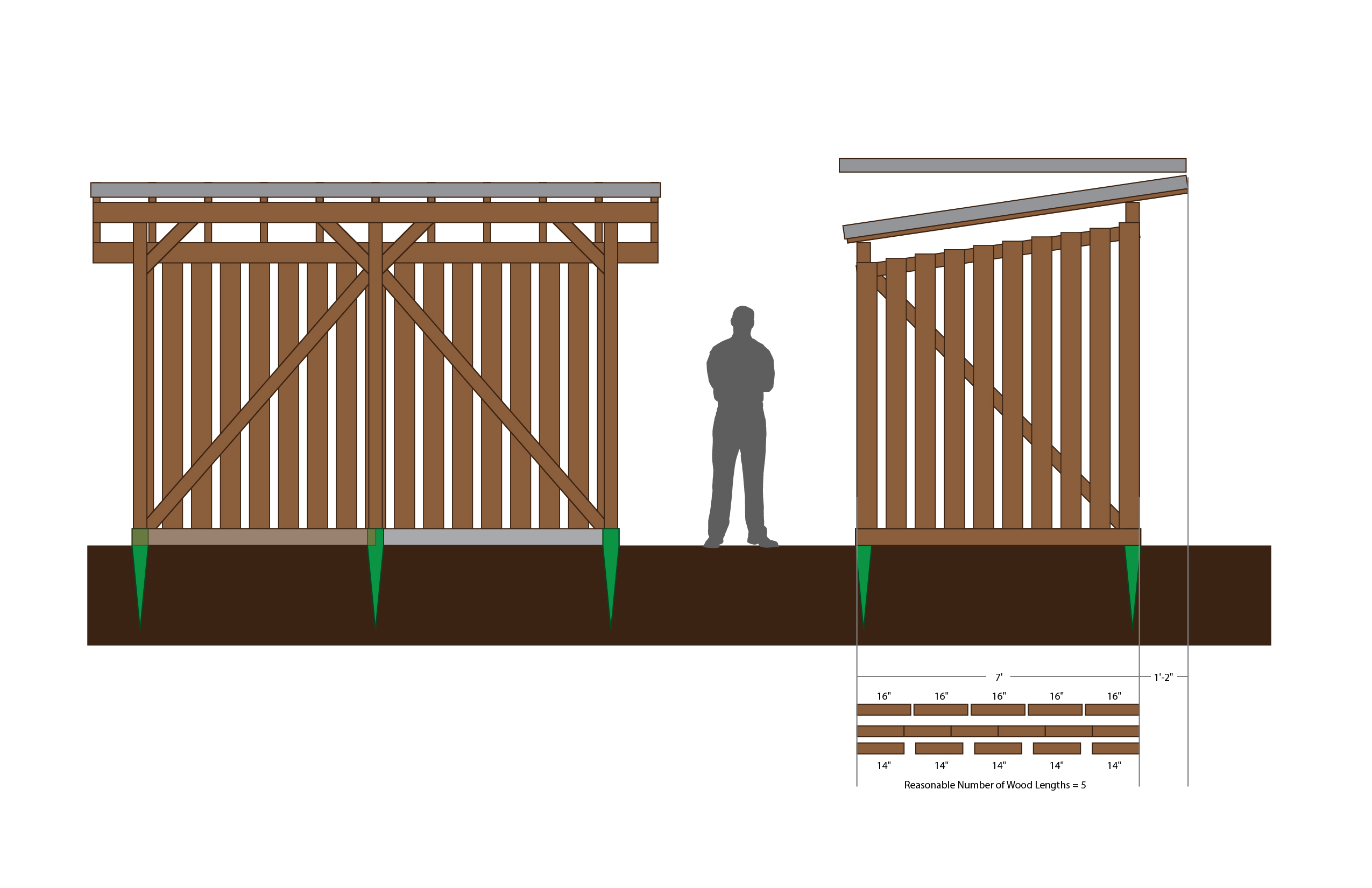

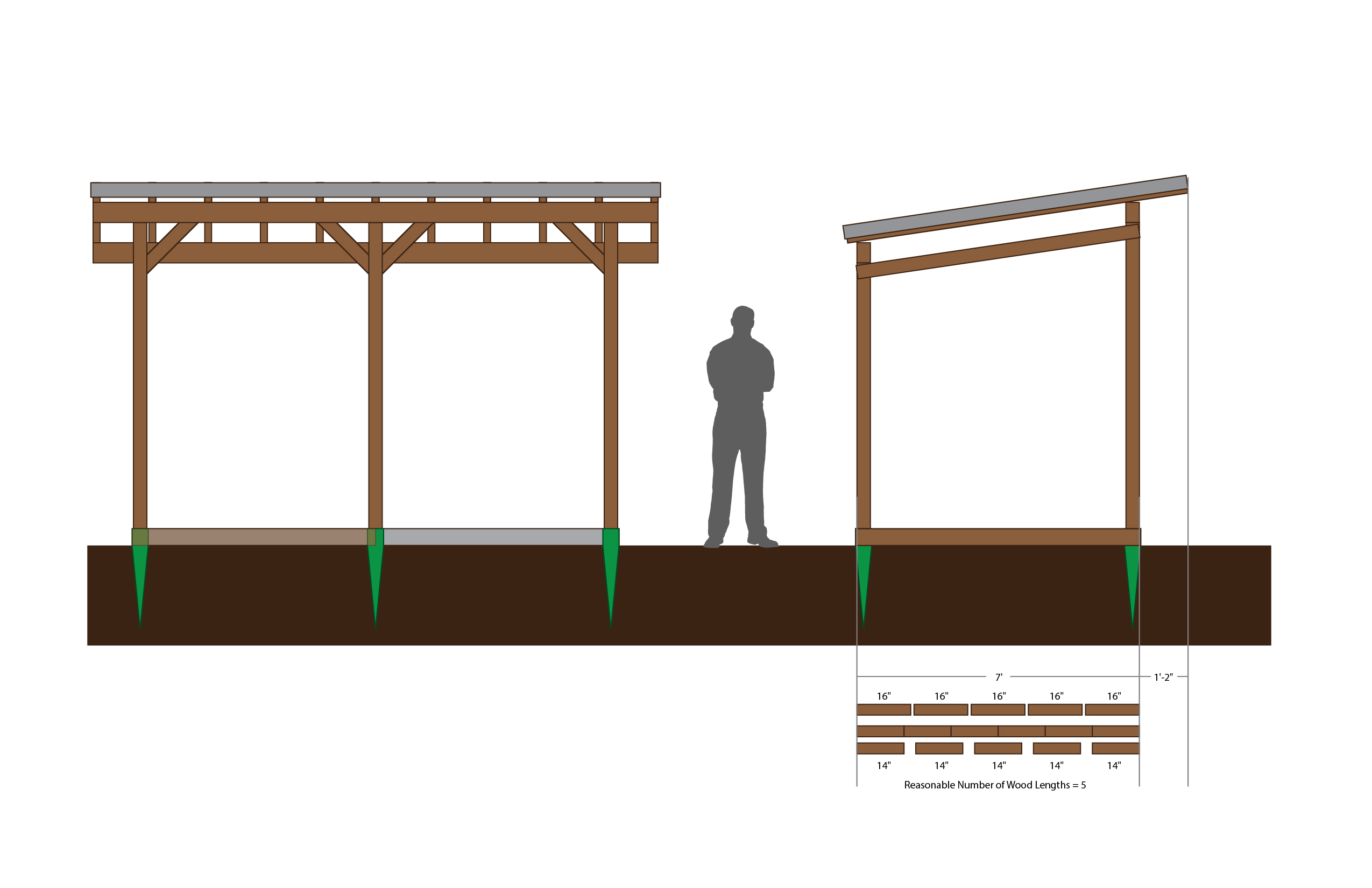

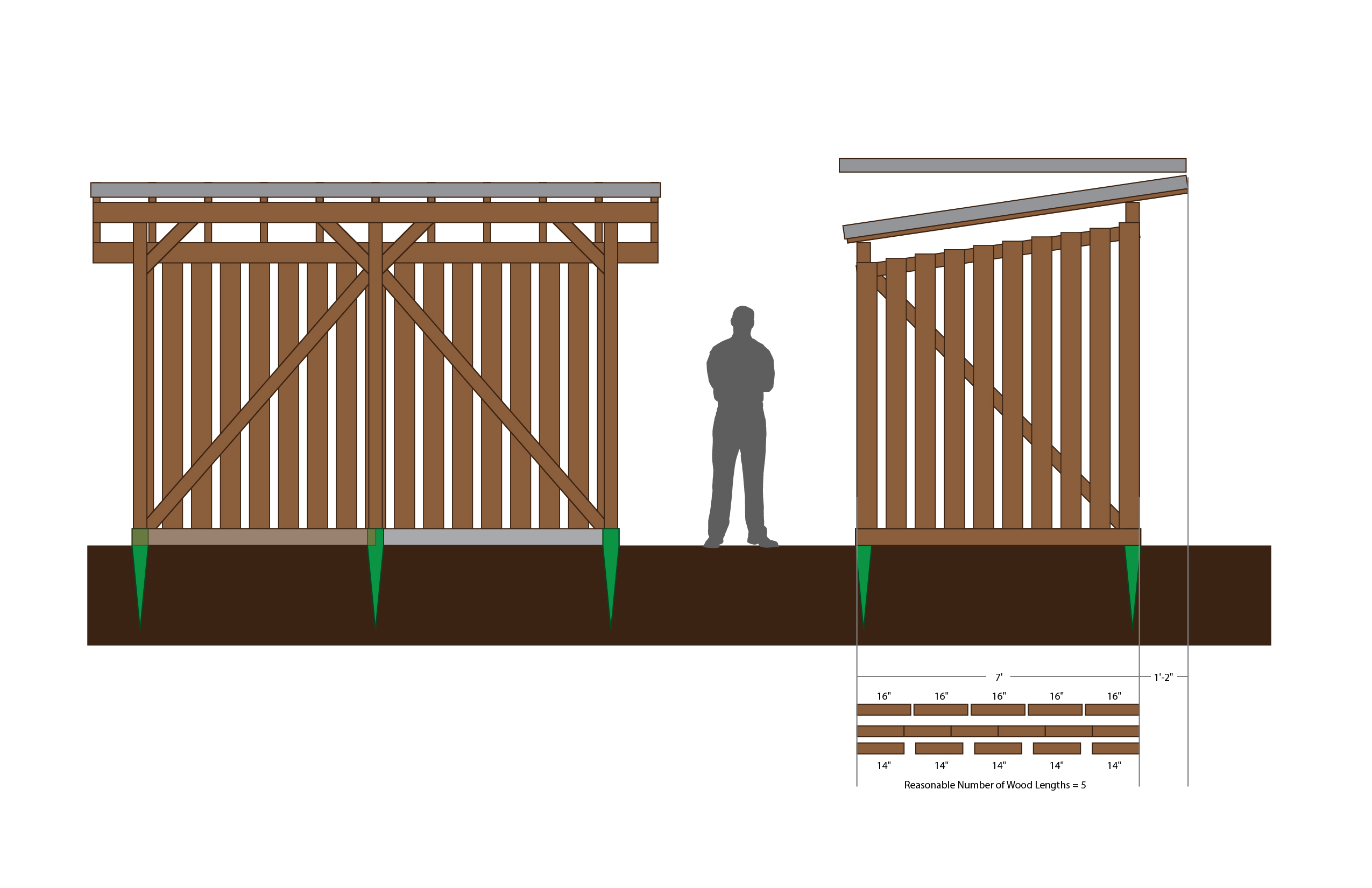

Please feel free to check out the photos posted and let me know what you think! I'll create a new thread and link back to this once I start the build.

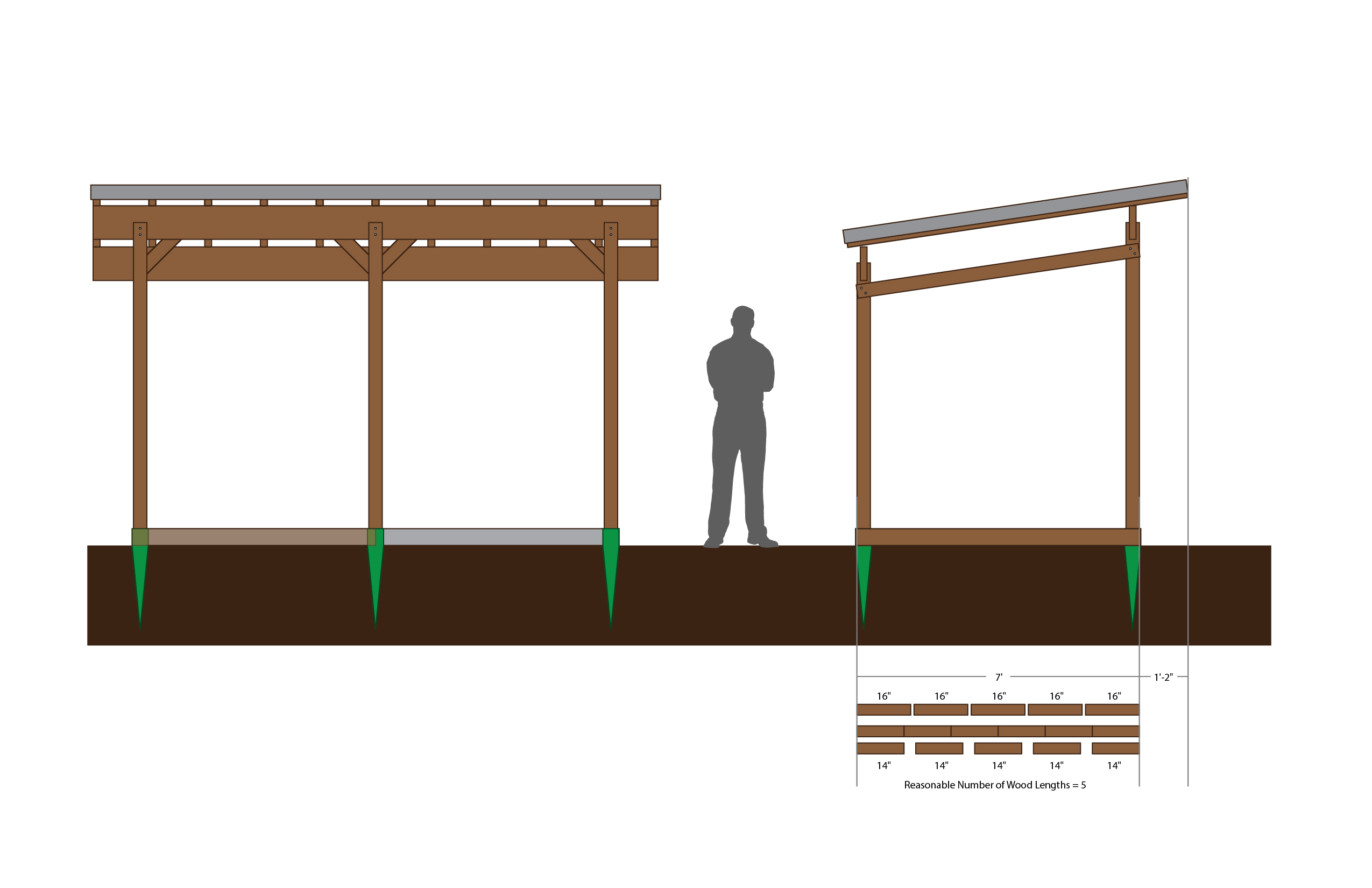

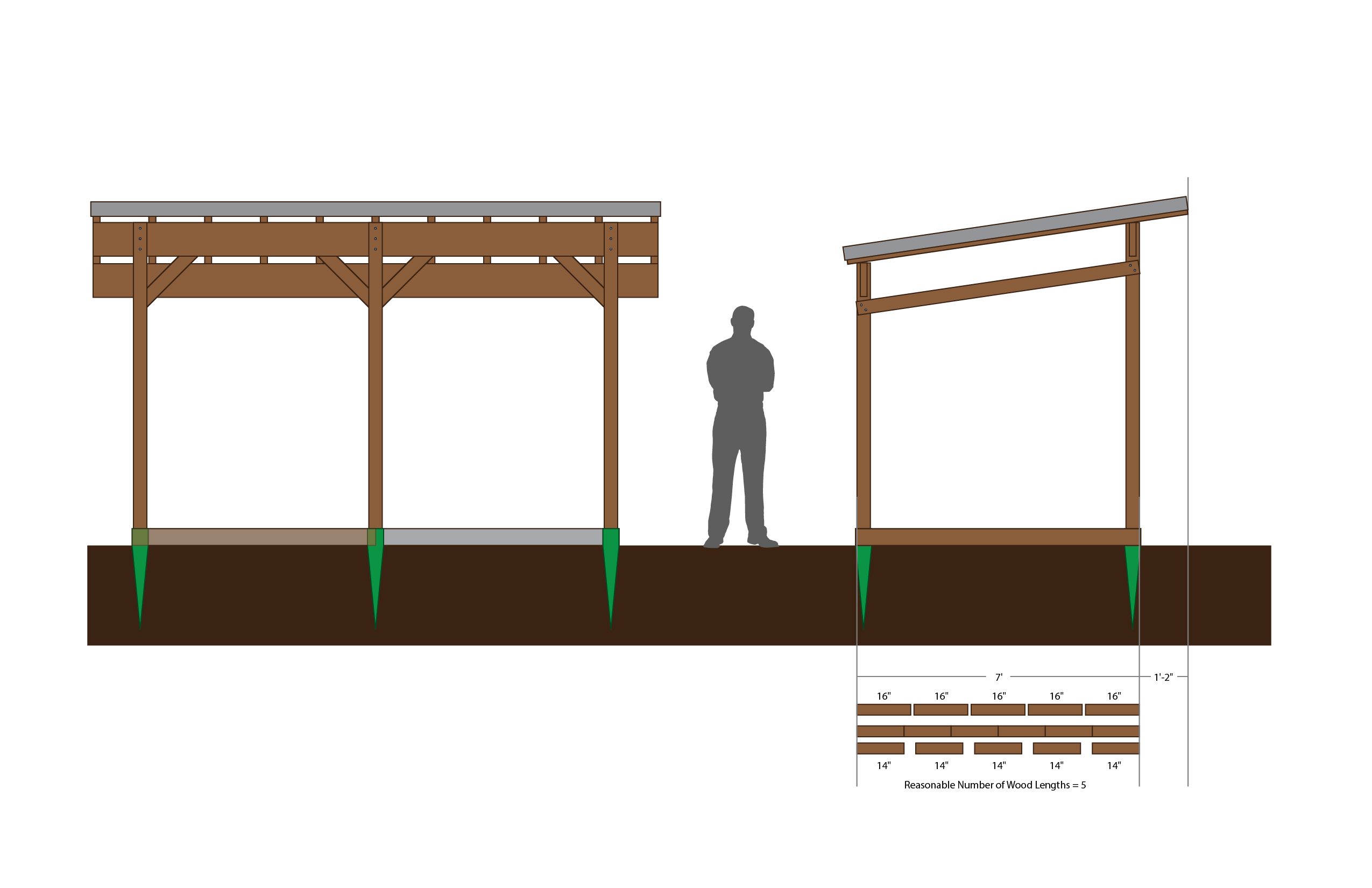

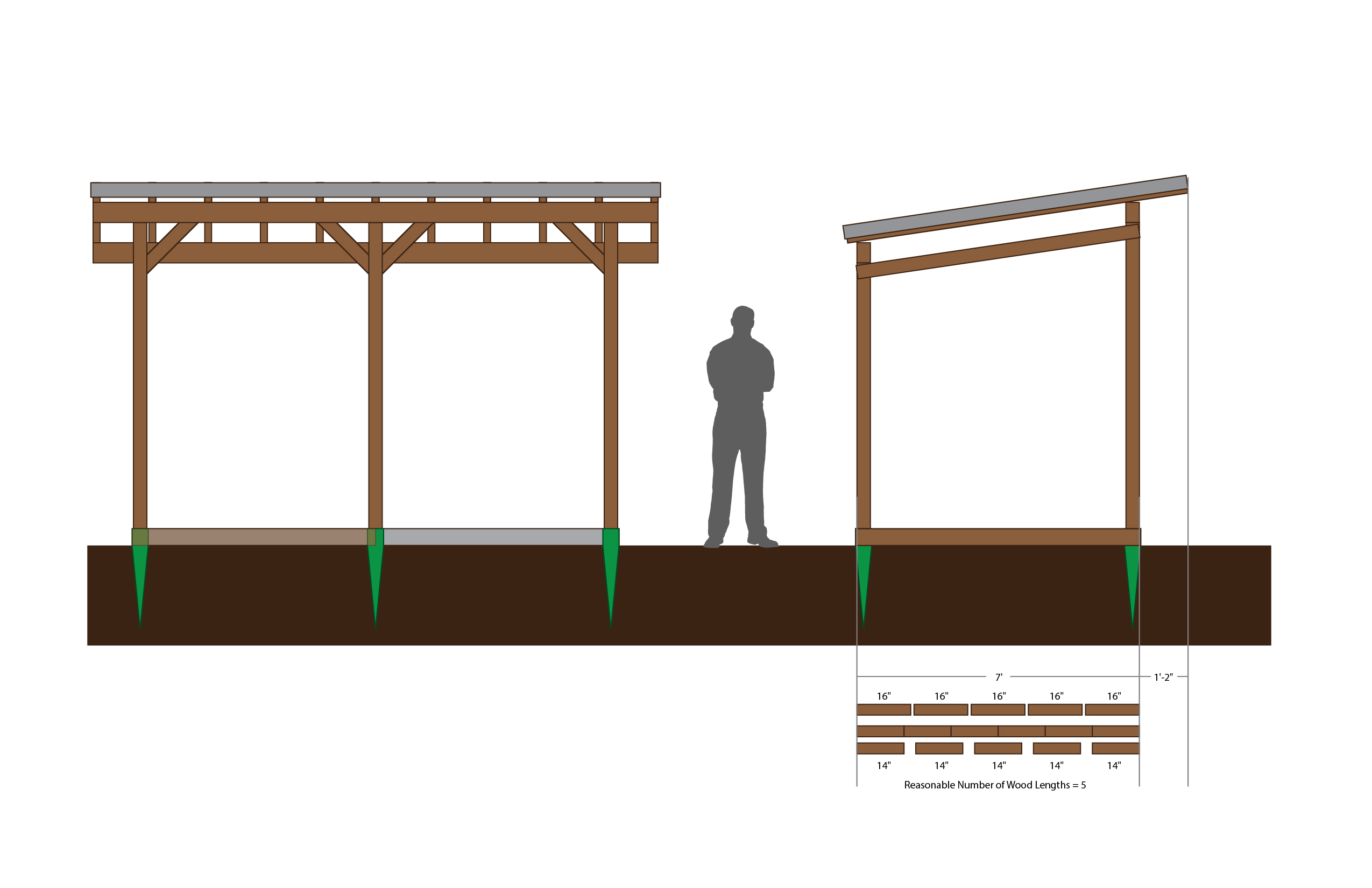

The footprint dimensions are 12x7. Seems weird I know, but it works out better with the wood lengths I'll be using. I'm going to be cutting all my wood to 14" from now on to fit in my Osburn Matrix which burns much better NS than EW. Will be 8' high in the front and 7' high in the back. I plan on stacking to about six or seven feet high.

Top beams: 4x6x14'

Vert posts: 4x4x8'

Side planking: 1x6x8' cedar

Everything else: 2x4 of varying length

Things I've settled on:

1. Roughly 4 cord capacity. This is my first wood burning year and so far I'm at about the 1.25 cord mark. In Chico CA where I live, we've passed peak burn season and we're only having evening fires these days. The plan is to have two cords worth saved up for winter burning per side. One side will be the current season and the other will be for the next year. I'll season wood during the summer outside the shed and then move it in the fall. The goal is to get three winters ahead so I can have 4 seasoned cords in the shed should I need more than two cords in a winter. I've been cutting all my wood this winter because we get a lot of sun and I like working in the cold over the 100 degree summer heat.

2. Gravel or crushed granite floor. Because I'll be stacking pretty high, I'm planning on having everything on the ground. Running floor joists seemed like a lot more work, engineering, and wood than necessary. I'm not into pallets either. While free/cheap, I want to keep my neighbor happy as this will run right on the property line. Plus they're always different sizes and I don't feel like playing Pallet Tetris.

3. Sliding barn door (not pictured). I have some old barn door hardware laying around and I thought I'd use it to make a sliding door for the front of the shed. I can load my two cords in and slide the door over. It's purely an aesthetic feature, but I think the asymmetry and hardware will look kind of cool.

Things I'm still thinking about:

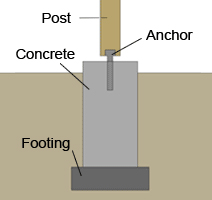

1. Anchoring the shed. Right now, I'm leaning towards these 4x4 stakes that you pound into the ground and set your posts into. I got em for $16 at Lowes. They seem like they'll last longer than pouring concrete around the posts. I've been replacing our 4x4 vertical fence posts which have started deteriorating and I don't want to have to do this to the shed any time soon. As far as driving the stakes goes, the soil is this wonderful rich loam topsoil which is a breeze to work with. I pounded one in about 2/3 of the way today and it seemed pretty darn sturdy.

See here if you don't know what I mean (I don't have the Lowes link): http://www.homedepot.com/p/Simpson-...er-Coated-12-Gauge-E-Z-Spike-FPBS44/100655352

Originally I was thinking about pier blocks, but as you can see from the design I think it'll be easier to contain the gravel if the posts are closer to the ground. With piers on top of the ground the gravel will spill out. Then I can run treated 2x6s around the perimeter to contain the gravel. Now I could bury the pier blocks, set them in concrete, and leave just the top barely sticking out, but this seemed like a lot more work than needed although much sturdier. I'm definitely open to opinions on this one. Note: Where the shed is located there is not a lot of wind exposure as it's protected mostly by the house next door. I'm not too worried about it blowing over.

2. Not using pressure treated wood for the vertical posts. I think I can get away with not using pressure treated wood since the posts won't be in the ground. What do you think? I'd rather not use it if possible just so everything looks the same. It's more an aesthetic preference, but mixing the wood colors seems a little cheesy.

3. Hardware. What would you guys recommend for hardware? I was thinking lags for the big beams and screws for everything else. I want it to be solid!

I would appreciate any feedback!

Thanks!

Oliver

Please feel free to check out the photos posted and let me know what you think! I'll create a new thread and link back to this once I start the build.

The footprint dimensions are 12x7. Seems weird I know, but it works out better with the wood lengths I'll be using. I'm going to be cutting all my wood to 14" from now on to fit in my Osburn Matrix which burns much better NS than EW. Will be 8' high in the front and 7' high in the back. I plan on stacking to about six or seven feet high.

Top beams: 4x6x14'

Vert posts: 4x4x8'

Side planking: 1x6x8' cedar

Everything else: 2x4 of varying length

Things I've settled on:

1. Roughly 4 cord capacity. This is my first wood burning year and so far I'm at about the 1.25 cord mark. In Chico CA where I live, we've passed peak burn season and we're only having evening fires these days. The plan is to have two cords worth saved up for winter burning per side. One side will be the current season and the other will be for the next year. I'll season wood during the summer outside the shed and then move it in the fall. The goal is to get three winters ahead so I can have 4 seasoned cords in the shed should I need more than two cords in a winter. I've been cutting all my wood this winter because we get a lot of sun and I like working in the cold over the 100 degree summer heat.

2. Gravel or crushed granite floor. Because I'll be stacking pretty high, I'm planning on having everything on the ground. Running floor joists seemed like a lot more work, engineering, and wood than necessary. I'm not into pallets either. While free/cheap, I want to keep my neighbor happy as this will run right on the property line. Plus they're always different sizes and I don't feel like playing Pallet Tetris.

3. Sliding barn door (not pictured). I have some old barn door hardware laying around and I thought I'd use it to make a sliding door for the front of the shed. I can load my two cords in and slide the door over. It's purely an aesthetic feature, but I think the asymmetry and hardware will look kind of cool.

Things I'm still thinking about:

1. Anchoring the shed. Right now, I'm leaning towards these 4x4 stakes that you pound into the ground and set your posts into. I got em for $16 at Lowes. They seem like they'll last longer than pouring concrete around the posts. I've been replacing our 4x4 vertical fence posts which have started deteriorating and I don't want to have to do this to the shed any time soon. As far as driving the stakes goes, the soil is this wonderful rich loam topsoil which is a breeze to work with. I pounded one in about 2/3 of the way today and it seemed pretty darn sturdy.

See here if you don't know what I mean (I don't have the Lowes link): http://www.homedepot.com/p/Simpson-...er-Coated-12-Gauge-E-Z-Spike-FPBS44/100655352

Originally I was thinking about pier blocks, but as you can see from the design I think it'll be easier to contain the gravel if the posts are closer to the ground. With piers on top of the ground the gravel will spill out. Then I can run treated 2x6s around the perimeter to contain the gravel. Now I could bury the pier blocks, set them in concrete, and leave just the top barely sticking out, but this seemed like a lot more work than needed although much sturdier. I'm definitely open to opinions on this one. Note: Where the shed is located there is not a lot of wind exposure as it's protected mostly by the house next door. I'm not too worried about it blowing over.

2. Not using pressure treated wood for the vertical posts. I think I can get away with not using pressure treated wood since the posts won't be in the ground. What do you think? I'd rather not use it if possible just so everything looks the same. It's more an aesthetic preference, but mixing the wood colors seems a little cheesy.

3. Hardware. What would you guys recommend for hardware? I was thinking lags for the big beams and screws for everything else. I want it to be solid!

I would appreciate any feedback!

Thanks!

Oliver