Man, my head is still spinning from mr.fixit's post, which seemed so easy at first, but made my head hurt as I tried to think about it more. Hopefully this will be more straightforward.

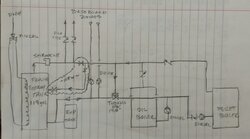

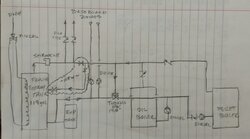

I plan to make the changes in the bubble marked 'new' in the diagram come summer. (Note: not all isolation valves shown.) It doesn't involve much piping and is reversible by closing a couple of valve. Comments?

Background: When I was first starting things up I had the boiler feed pumps set pretty high, which caused the first floor zone to heat up some since I guess flow went past the Taco flo-chk valve. There's a circ pump for each zone and they pump towards return. Since I turned down the speed, everything is fine. It's working fine, so why mess with a good thing, right? Fatal flaw, I guess. Writing about it also helps me think about it more too, I guess.

The way I look at my buffer tank is that it takes up excess heat generated by the pellet boiler, allows longer run times, longer times between starts, and therefore fewer starts. I'm still using a wood insert, so the 15kw boiler primarily warms up the second floor, dhw, and generally provides baseline comfort. While it modulates down to 30%, with the insert running, it's too much, so hence, the buffer tank.

Right now, when the boiler is running and the boiler feed pump is on, the loads get first crack at the supply water-excess goes to buffer tank via the top connection. When the boiler is off and a load comes on, flow is reversed through the top connection, and the loads are supplied by the buffer tank.

I propose to change the flow through the top connection to only one direction: out, supplying heated water to the zones. The boiler supply will be connected to a point 1/3 down from the top of the tank.

The buffer tank is a Froling Energy Tank. http://www.woodboilers.com/images/stories/documents/energy-tank-rev5.pdf

It supposedly has baffles built in to help with stratification. I don't notice much stratification going on when the boiler feed pump is running the way it is plumbed now, one connection, from the top. When the boiler feed pump is off, yes, stratification, for sure.

The way it is plumbed now, I get a nice heat fill, to around 180 at the sensors at the top and 1/3 down from the top. So, i'm happy there.

Even though the supply would be 1/3 down from the top, I think the supply to the zones would still be receiving the benefit of the hot water coming off a running boiler since it should go to the top.

What do you think.

Gotta go, ran out of time. Too cold for anything but a movies.

Thanks.

I plan to make the changes in the bubble marked 'new' in the diagram come summer. (Note: not all isolation valves shown.) It doesn't involve much piping and is reversible by closing a couple of valve. Comments?

Background: When I was first starting things up I had the boiler feed pumps set pretty high, which caused the first floor zone to heat up some since I guess flow went past the Taco flo-chk valve. There's a circ pump for each zone and they pump towards return. Since I turned down the speed, everything is fine. It's working fine, so why mess with a good thing, right? Fatal flaw, I guess. Writing about it also helps me think about it more too, I guess.

The way I look at my buffer tank is that it takes up excess heat generated by the pellet boiler, allows longer run times, longer times between starts, and therefore fewer starts. I'm still using a wood insert, so the 15kw boiler primarily warms up the second floor, dhw, and generally provides baseline comfort. While it modulates down to 30%, with the insert running, it's too much, so hence, the buffer tank.

Right now, when the boiler is running and the boiler feed pump is on, the loads get first crack at the supply water-excess goes to buffer tank via the top connection. When the boiler is off and a load comes on, flow is reversed through the top connection, and the loads are supplied by the buffer tank.

I propose to change the flow through the top connection to only one direction: out, supplying heated water to the zones. The boiler supply will be connected to a point 1/3 down from the top of the tank.

The buffer tank is a Froling Energy Tank. http://www.woodboilers.com/images/stories/documents/energy-tank-rev5.pdf

It supposedly has baffles built in to help with stratification. I don't notice much stratification going on when the boiler feed pump is running the way it is plumbed now, one connection, from the top. When the boiler feed pump is off, yes, stratification, for sure.

The way it is plumbed now, I get a nice heat fill, to around 180 at the sensors at the top and 1/3 down from the top. So, i'm happy there.

Even though the supply would be 1/3 down from the top, I think the supply to the zones would still be receiving the benefit of the hot water coming off a running boiler since it should go to the top.

What do you think.

Gotta go, ran out of time. Too cold for anything but a movies.

Thanks.