XXV may have to go

- Thread starter canuck_22

- Start date

-

Active since 1995, Hearth.com is THE place on the internet for free information and advice about wood stoves, pellet stoves and other energy saving equipment.

We strive to provide opinions, articles, discussions and history related to Hearth Products and in a more general sense, energy issues.

We promote the EFFICIENT, RESPONSIBLE, CLEAN and SAFE use of all fuels, whether renewable or fossil.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

- Status

- Not open for further replies.

Ok, here we go. The high draft makes no sense whatsoever to me, so I connected my gauge, put the stove in test mode and proceeded to change parts on the vent as follows, the reading observed right off the bat was -.80~85.

1) Remove the new jet cap no change

no change

2) Add 24 inches vertical no change

no change

3) Add the jet cap to that nochange

nochange

4) Put the old cap back on no change

no change

So, no matter what I do, no change and it's as low as it goes.

Time to pull it out, disconnect at the exhaust(see pics), disconnect the OAK (see pics)

Put the gauge back in, test mode, -.70 on high then -.25 afterwards, all makes sense as nothing is in there to cause a restriction. Introduce my hand and rag to the OAK port, the gauge rises to -.50~60~65, so that tells me a high number means starving/restriction!

As I devised the OAK adapter 3 inch to 2 inch using automotive exhaust parts siliconed together then attach it to the 2 inch flex, this had to be a problem hence starving the stove. I cant see other explanations. Now maybe the igniter is not getting enough air to fire up the pellets!

Let the feedback pour in

1) Remove the new jet cap

no change

no change2) Add 24 inches vertical

no change

no change3) Add the jet cap to that

nochange

nochange4) Put the old cap back on

no change

no changeSo, no matter what I do, no change and it's as low as it goes.

Time to pull it out, disconnect at the exhaust(see pics), disconnect the OAK (see pics)

Put the gauge back in, test mode, -.70 on high then -.25 afterwards, all makes sense as nothing is in there to cause a restriction. Introduce my hand and rag to the OAK port, the gauge rises to -.50~60~65, so that tells me a high number means starving/restriction!

As I devised the OAK adapter 3 inch to 2 inch using automotive exhaust parts siliconed together then attach it to the 2 inch flex, this had to be a problem hence starving the stove. I cant see other explanations. Now maybe the igniter is not getting enough air to fire up the pellets!

Let the feedback pour in

Attachments

SmokeyTheBear

Minister of Fire

Wonderful you confirmed that the OAK is supposed to be the same size and at least as big enough to fit over the stoves air intake. Besides playing and now having enough information to kick the vent dealer with is the stove running?

ETA: An since you were poking around I hope you cleaned the crud in the exhaust system out as well.

ETA: An since you were poking around I hope you cleaned the crud in the exhaust system out as well.

No, it's all disconnected, will have to get a new thimble with a 3 inch or a plain thimble with a separate oak kit. Not sure now if I need an igniter, might get one just in case. I might as well get the new Harman adapter while I'm at it. I did not like the build up of crap as you can see in the pics, maybe because it was not burning well. A Selkirk DT would be the ultimate, but I dont think my hole is big enough.Wonderful you confirmed that the OAK is supposed to be the same size and at least as big enough to fit over the stoves air intake. Besides playing and now having enough information to kick the vent dealer with is the stove running?

Yes I did vacuum the crud.

SmokeyTheBear

Minister of Fire

Just let us know when you are going playing so we don't just sit around waiting for burn pictures and CO meter readings. I suspect this thread has a few watchers.

MarkF48

Feeling the Heat

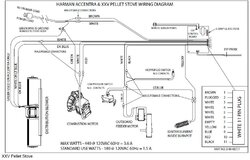

Just a technical point, the ignitor is fed through the low pressure switch from a wire which being white I would take as the "neutral" and is a current carrying wire. The other wire from the ignitor (yellow) connects back to the control board and likely is fed through a relay from the "hot" side of the line, also a current carrying conductor. The "ground" in the stove is more for safety and protection and wouldn't/shouldn't carry any operating current of the stove. The stove and ignitor could conceivably function without the ground, but not without the neutral. Since the pellet feed motor operates, the neutral conductor that feeds the low pressure switch appears to be intact and the pressure switch is functioning properly.If you have 110+ volts and a good ground then it's the igniter

jmo

On a remote chance canuck has a Kill a Watt power meter , he could check the power draw when the ignitor is supposed to be powered up. According to the wiring diagram maximum rated current/power draw is 3.6amps/440watts, a portion of which will be the ignitor. If the reading doesn't get up that high it's likely the ignitor is faulty.

My suggestion to disconnect the OAK was just meant to be only temporary as a means to troubleshoot the possible reason the ignitor didn't adequately heat up in an expected time frame, by no means a permanent fix. Crack open a window for a short while if the house is sealed up tight while doing this. I would hope the house wouldn't explode while doing this. Might be interesting to get a comparative reading of the draft while disconnected also (edit.. see in the above post you did this). Yeah, it should be designed to work correctly with the recommended OAK, but why not try it without and see if there is a different outcome.

Smokey, can you recommend an online seller to get a decent draft gauge. Keep thinking about adding one to rest of tools I have, but haven't gotten around to searching one out yet.

Last edited:

Bioburner

Moderator

Slight starvation of any flame can lead to CO too.

Just a technical point, the ignitor is fed through the low pressure switch from a wire which being white I would take as the "neutral" and is a current carrying wire. The other wire from the ignitor (yellow) connects back to the control board and likely is fed through a relay from the "hot" side of the line, also a current carrying conductor. The "ground" in the stove is more for safety and protection and wouldn't/shouldn't carry any operating current of the stove. The stove and ignitor could conceivably function without the ground, but not without the neutral. Since the pellet feed motor operates, the neutral conductor that feeds the low pressure switch appears to be intact and the pressure switch is functioning properly.

On a remote chance canuck has a Kill a Watt power meter , he could check the power draw when the ignitor is supposed to be powered up. According to the wiring diagram maximum rated current/power draw is 3.6amps/440watts, a portion of which will be the ignitor. If the reading doesn't get up that high it's likely the ignitor is faulty.

My suggestion to disconnect the OAK was just meant to be only temporary as a means to troubleshoot the possible reason the ignitor didn't adequately heat up in an expected time frame, by no means a permanent fix. Crack open a window for a short while if the house is sealed up tight while doing this. I would hope the house wouldn't explode while doing this. Might be interesting to get a comparative reading of the draft while disconnected also. Yeah, it should be designed to work correctly with the recommended OAK, but why not try it without and see if there is a different outcome.

Smokey, can you recommend an online seller to get a decent draft gauge. Keep thinking about adding one to rest of tools I have, but haven't gotten around to searching one out yet.

View attachment 154328

I own 2 Kill a watt, great tool, will do the test when I put it back together.

Smokey, this wont be done until next weekend, I'll call for the parts tomorrow. I suspect it will be miserable to pull off the adapter from the exhaust.

SmokeyTheBear

Minister of Fire

You know MarkF48 I always mention setting up to the manual using one but my stove has no setting to adjust to and no way to do an adjustment so I don't have one. Funny that huh?

Last edited:

SmokeyTheBear

Minister of Fire

First ya got to generate the CO and then you've got to disperse it. If ya don't generate a lot of it you don't need too much good air to make what concentration is there inconsequential.

SmokeyTheBear

Minister of Fire

I own 2 Kill a watt, great tool, will do the test when I put it back together.

Smokey, this wont be done until next weekend, I'll call for the parts tomorrow. I suspect it will be miserable to pull off the adapter from the exhaust.

Ok not a problem.

Luv2burnPellets

Member

I for one am watching closely. I am super impressed with Canuck-22 being so determined and trying everything he can to get to the bottom of it. Also my hat is off to Smokey for sharing his knowledge and being so genuinely helpful. A solution is imminent!Just let us know when you are going playing so we don't just sit around waiting for burn pictures and CO meter readings. I suspect this thread has a few watchers.

Luv2burnPellets

Member

He has a Dwyer magnahelic draft gage, which I think is an extremely high quality gage.Just a technical point, the ignitor is fed through the low pressure switch from a wire which being white I would take as the "neutral" and is a current carrying wire. The other wire from the ignitor (yellow) connects back to the control board and likely is fed through a relay from the "hot" side of the line, also a current carrying conductor. The "ground" in the stove is more for safety and protection and wouldn't/shouldn't carry any operating current of the stove. The stove and ignitor could conceivably function without the ground, but not without the neutral. Since the pellet feed motor operates, the neutral conductor that feeds the low pressure switch appears to be intact and the pressure switch is functioning properly.

On a remote chance canuck has a Kill a Watt power meter , he could check the power draw when the ignitor is supposed to be powered up. According to the wiring diagram maximum rated current/power draw is 3.6amps/440watts, a portion of which will be the ignitor. If the reading doesn't get up that high it's likely the ignitor is faulty.

My suggestion to disconnect the OAK was just meant to be only temporary as a means to troubleshoot the possible reason the ignitor didn't adequately heat up in an expected time frame, by no means a permanent fix. Crack open a window for a short while if the house is sealed up tight while doing this. I would hope the house wouldn't explode while doing this. Might be interesting to get a comparative reading of the draft while disconnected also (edit.. see in the above post you did this). Yeah, it should be designed to work correctly with the recommended OAK, but why not try it without and see if there is a different outcome.

Smokey, can you recommend an online seller to get a decent draft gauge. Keep thinking about adding one to rest of tools I have, but haven't gotten around to searching one out yet.

View attachment 154328

He has a Dwyer magnahelic draft gage, which I think is an extremely high quality gage.

I do

SmokeyTheBear

Minister of Fire

And just so everyone understands the igniter needs a very good airflow past it to do its job in the time allotted before the control system says failed ignition.

MarkF48

Feeling the Heat

And the airflow likely will probably help significantly with the issue of the innards of the stove getting gummed up that he hadAnd just so everyone understands the igniter needs a very good airflow past it to do its job in the time allotted before the control system says failed ignition.

Last edited:

Well folks, after a week of reflecting, information gathering from pros here and in my area, I risk not succeeding, sink more money with bad results. Three different dealers have spelled it out the same way and that convinced me at the end of the day, 1) my stove is on the wrong wall with no options, North/East=nasty super cold winds 2) Long vent pipes outside instead of inside means "gummy" pipes and stove = troubles, long pipes will always remain cold and condense, soot, gum up, not good. So I sold the XXV stove this afternoon, they are picking it up Sunday, my spouse wont have to deal with this when I travel on business. Sorry folks, I wish I could say I fired it up and report back with something more helpful, I take my loss and move on. The P61A on the west side of the house chugs along very nicely, at the end of the day only one stove to baby. With the new gas furnace coming in May, it will have an additional cold air return expressly for the P61A, the ECM motor on the furnace will run 24/7, my furnace installer says it should produce nice results, in other words maximize the use of the pellet stove by distributing more evenly. I wish to thank everyone for their help, appreciated. PS, I have mixed feelings about my dealer's assistance, pellet sales next year will be awarded elsewhere, same goes for service parts.

Ambient

Member

Our natural inclinations drive us to be stubborn, yet with age comes more wisdom. I found that the Spouse being happy is half any battle. Sorry it didn't work out for you.

Our natural inclinations drive us to be stubborn, yet with age comes more wisdom. I found that the Spouse being happy is half any battle. Sorry it didn't work out for you.

Yup happy wife happy house, this is what she is getting instead, press button on press button off. I'm confident the P61A in the basement is still going to give me savings.

Attachments

- Status

- Not open for further replies.

Similar threads

- Replies

- 8

- Views

- 965

- Replies

- 9

- Views

- 2K

- Replies

- 50

- Views

- 2K

- Replies

- 36

- Views

- 3K