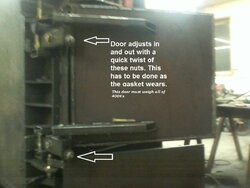

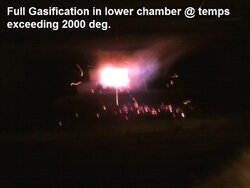

Hi everyone, my names Aaron I'm new to the forum. I am a proud owner of what I call BIG RED, my homemade gasser. I am in the excavation business, but also own a welding shop, so I decided to build a gasifier myself to replace my central boiler. which is a story of it's own, rotting from the outside - inward under the spray foam. This after only 15 years! Anyway I will attach some picts and answer any questions should anyone be inspired to take on a project like this. A few stats. the boiler is 3/8" thick fire box, 1/4" water jacket and boiler tube design. the fire box is around 45 cubic ft and the boiler holds approx. 550 gals of water. Yes I have a huge heat load!

Last edited by a moderator: