Good morning.

I have been doing a bunch of reading of old posts on the site this weekend and have now started to wonder if I am getting the most efficient use of my boiler.

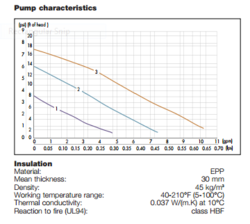

I have an Econoburn 200K boiler and 1000 gallon storage and have always assumed I am moving enough heat from one to the other. My pump from boiler to storage is a Caleffi 280 series loading unit. The pump chart is attached. I am using 1 1/4 inch copper piping. You can see in my avatar that my boiler is right beside storage. My pump is located at floor level on the return to the boiler. Above the boiler is about 4 foot rise and then another 6-7 feet across to the tanks.

I have always figured that since my boiler is not coasting when I run the pump on speed 3 then I am moving enough water. I am no good with the math and pump charts so can anyone offer me up a quick opinion. I would hate to be burning wood to create heat that is not making it to storage.

I have been doing a bunch of reading of old posts on the site this weekend and have now started to wonder if I am getting the most efficient use of my boiler.

I have an Econoburn 200K boiler and 1000 gallon storage and have always assumed I am moving enough heat from one to the other. My pump from boiler to storage is a Caleffi 280 series loading unit. The pump chart is attached. I am using 1 1/4 inch copper piping. You can see in my avatar that my boiler is right beside storage. My pump is located at floor level on the return to the boiler. Above the boiler is about 4 foot rise and then another 6-7 feet across to the tanks.

I have always figured that since my boiler is not coasting when I run the pump on speed 3 then I am moving enough water. I am no good with the math and pump charts so can anyone offer me up a quick opinion. I would hate to be burning wood to create heat that is not making it to storage.