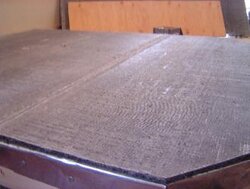

We are in the process of planning a new hearth for our wood stove due to an unsafe condition that currently exists. Since we want to do this right, we are turning to the experts for help. This will be for a chimney in an interior wall. The chimney is constructed of 16” square concrete chimney block with a 6” terra cotta flue. The terra cotta thimble extends about 10 inches into our living room, where the stove will be located. The other three sides of the chimney are in a closet. Our plan is to “box-in” our chimney using steel studs and Durock with the studs being 2 inches from the chimney and the Durock about 5 ½” from the chimney (2 inches plus the stud width). Hopefully, this will give us a non-combustible wall behind the stove and the proper clearances around the other sides of the chimney.

Our questions right now are these:

Does this type of framing sound acceptable?

Is it necessary to use Durock for the 3 walls in the closet or can they be regular drywall if they are behind a non-combustible wall and are the recommended distance from our stove for a combustible wall?

What should we do around the terra cotta thimble? Can the Durock go right up against it? Would we able to use single wall stovepipe going into the thimble with this type of construction?

Just for info: We are planning to replace our old Scandia stove with a new Hearthstone Craftsbury. We like the looks of it and it is in our price range. We will be heating about 1000 square feet in a ranch style log home.

Thanks!

Mike

Our questions right now are these:

Does this type of framing sound acceptable?

Is it necessary to use Durock for the 3 walls in the closet or can they be regular drywall if they are behind a non-combustible wall and are the recommended distance from our stove for a combustible wall?

What should we do around the terra cotta thimble? Can the Durock go right up against it? Would we able to use single wall stovepipe going into the thimble with this type of construction?

Just for info: We are planning to replace our old Scandia stove with a new Hearthstone Craftsbury. We like the looks of it and it is in our price range. We will be heating about 1000 square feet in a ranch style log home.

Thanks!

Mike