Found this on CL. Couldn't pass it up. Haven't even figure out how to get it off the trailer.

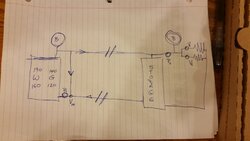

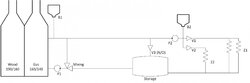

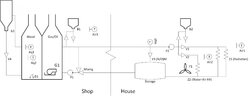

I am thinking about installing in detached garage (maybe in a to-be-created corner room).

House and garage currently have forced air oil/propane heating. Not above installing cast iron radiators.

Suggestions welcomed.

I am thinking about installing in detached garage (maybe in a to-be-created corner room).

House and garage currently have forced air oil/propane heating. Not above installing cast iron radiators.

Suggestions welcomed.

Last edited: